Preparation method of one-dimensional CdS nanorod/three-dimensional multilayer Ti3C2 composite photocatalyst

A three-dimensional multilayer, nanorod technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problem of accelerating photogenerated electron-hole polymerization depletion, reducing effective catalytic specific surface area, and limiting the application of CdS Development and other issues, to achieve the effect of improving electron transport capacity, reducing carrier recombination rate, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

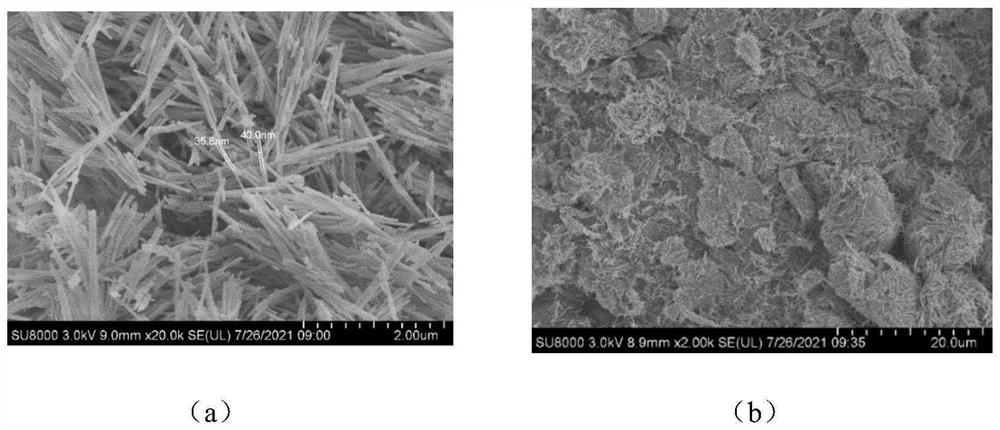

[0039] A 1D CdS nanorod / 3D multilayer Ti 3 C 2 The preparation method of composite photocatalyst specifically comprises the following steps:

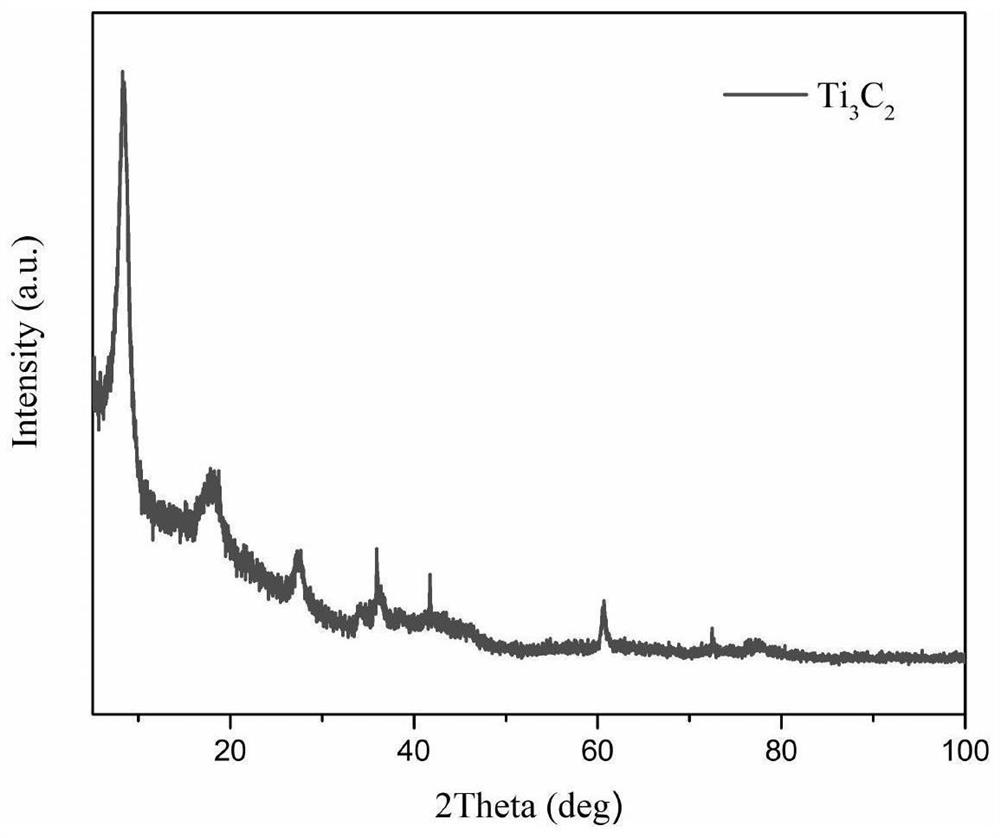

[0040] (1) get hydrofluoric acid in the reactor, place the reactor on a magnetic stirrer, weigh a certain amount of Ti 3 AlC 2 The powder is added to the hydrofluoric acid solution and reacted at a constant temperature for 20-28h;

[0041] (2) repeatedly washing the material obtained from the reaction in step (1) until the pH of the collected washing solution is 7, to remove residual hydrofluoric acid and Al 3+ ion;

[0042] (3) vacuum drying the material obtained in step (2) for 20-28h, and grinding the dried sample to obtain multilayer Ti 3 C 2 powder;

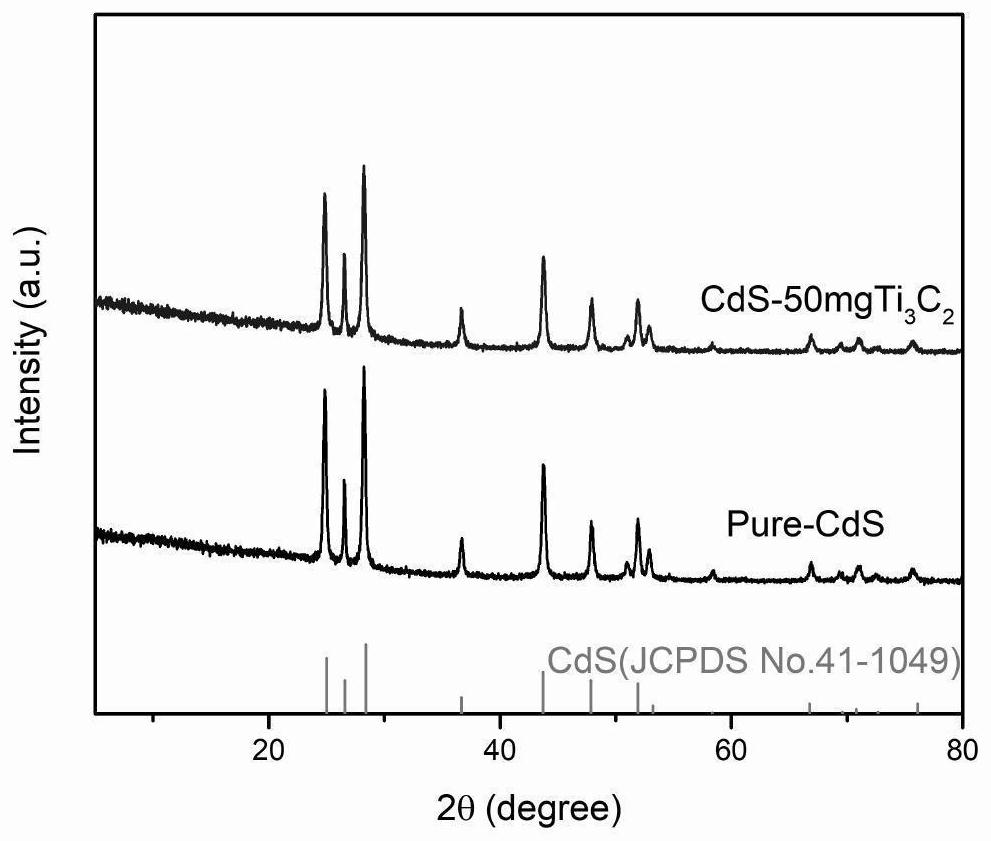

[0043] (4) Take the above-mentioned Ti of a certain quality 3 C 2 powder, make it uniformly dispersed in a certain volume of ethylenediamine solution to obtain Ti 3 C 2 / ethylenediamine solution, take cadmium nitrate (Cd(NO 3 ) 2 .4H 2 O) be dissolved in a certain volum...

Embodiment 1

[0055] (1) Take 20 mL of hydrofluoric acid with a mass fraction of 40 wt% in a polytetrafluoroethylene cup, place it on a magnetic stirrer and stir, and weigh 2 g of Ti 3 AlC 2 The powder was slowly added to the hydrofluoric acid solution for 10 minutes, and was reacted at a constant temperature of 40°C under stirring conditions for 24 hours;

[0056] (2) the material obtained by the reaction in the step (1) is washed alternately with water and alcohol until the pH of the washing solution is 7, to remove residual hydrofluoric acid and Al 3+ ion;

[0057] (3) vacuum-drying the material obtained in step (2) for 24 hours, and grinding the dried sample to obtain multilayer Ti 3 C 2 powder;

[0058] (4) take 50mg Ti obtained in step (3) 3 C 2 The powder was added to 30 mL of ethylenediamine solution, and ultrasonicated for 2 hours to make it evenly dispersed; take 15 mmol of cadmium nitrate (Cd(NO) 3 .4H 2 O), add to 20mL of ethylenediamine solution, stir to make it evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com