A foamed visible light catalytic material, preparation method and use thereof

A technology of photocatalytic materials and catalytic materials, applied in the field of semiconductor photocatalysis, to avoid the generation of by-products, solve the problem of light shielding, excellent photocatalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

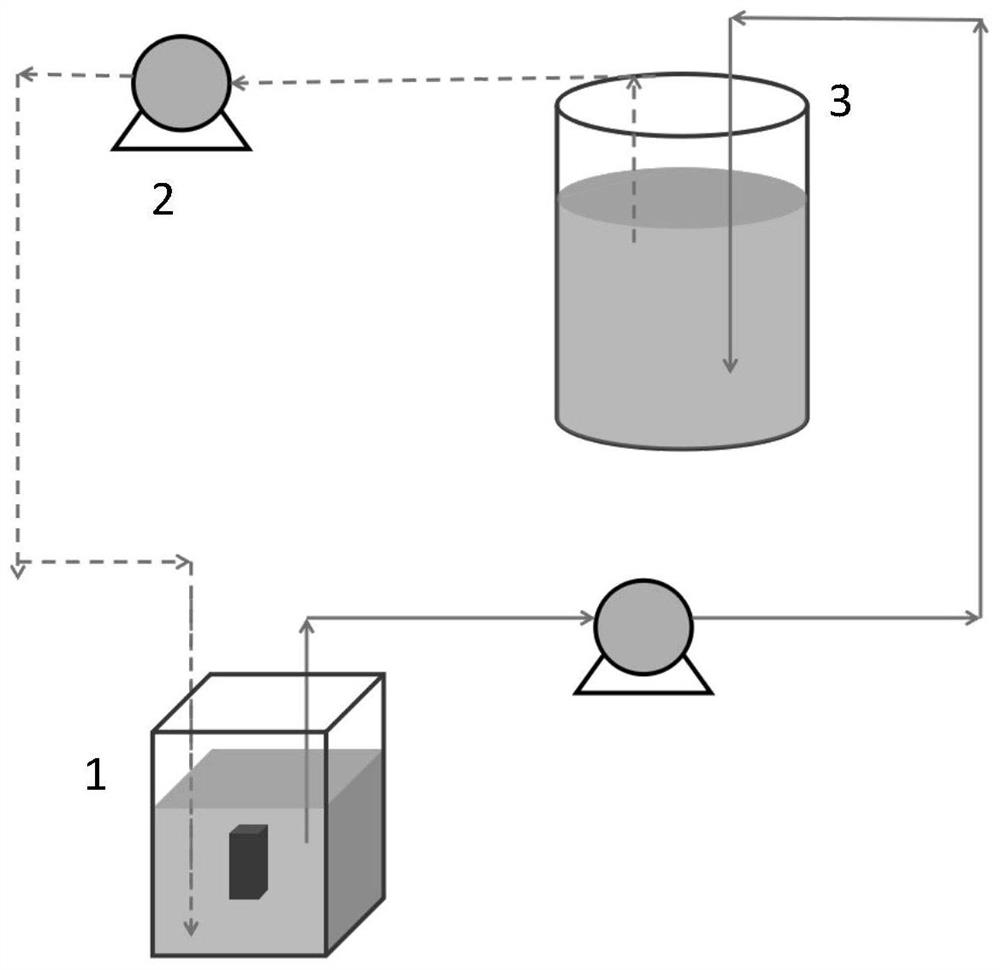

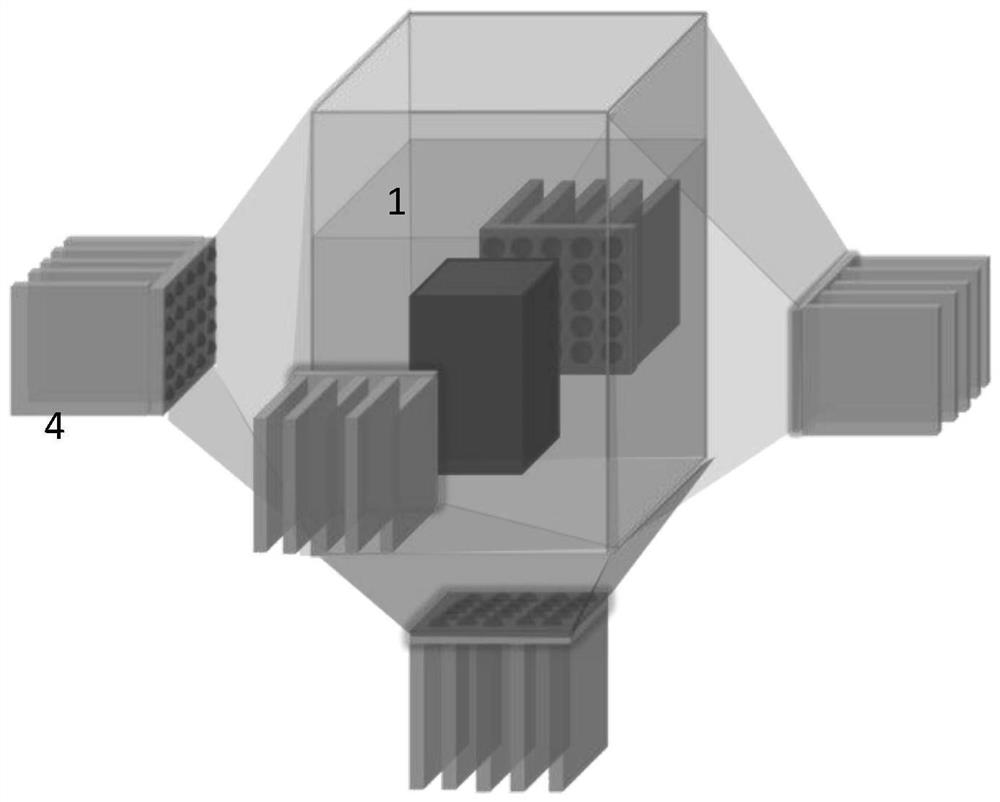

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the invention is simple and convenient, and the raw materials used are easy to obtain and low in price, can effectively avoid polluting by-products, and have no secondary pollution in the process. The prepared photocatalytic material has a low carrier recombination rate. The three-dimensional network structure can effectively increase the contact between the catalyst and pollutants, has excellent photocatalytic activity and stability, can be recycled, and has good practical application prospects. The foamy C of the present invention 3 N 4 Compared with the single powder, the / GO@MF photocatalytic material can effectively increase the adsorption capacity of pollutants, improve the photocatalytic performance, and the catalyst is easy to recycle.

[0041] The structure of the product prepared by the present invention is characterized by the following means: a Vario EL cube type elemental analyzer is used to analyze the composition of the sample....

Embodiment 1

[0046] Add 20 mg of graphene oxide (GO) to 38.5 mL of deionized water, and ultrasonicate for 60 min to make it uniformly dispersed. Add 2.0 g of urea (urea) to the GO dispersion and stir for 30 min to completely dissolve it in the GO dispersion. At this point, the concentrations of GO and urea in the precursor solution were 0.5 mg / mL and 50 mg / mL, respectively. Then melamine resin foam (MF) (1.5 × 1.5 × 2.0 cm) was immersed in the graphene oxide urea (GO-urea) solution, and GO and urea were uniformly dispersed on the MF by ultrasonication for 0.5 h. The foam adsorbed with GO and urea was placed in a 10 mL crucible with a lid and wrapped with tinfoil. Put it in a tube furnace, heat-treat and roast at 500°C for 4h in an argon atmosphere, and the heating rate is 2.5°C / min. After naturally cooling to room temperature, wash with water and absolute ethanol three times respectively, and vacuum dry at 55°C for 10 hours to obtain foamy C 3 N 4 / GO@MF photocatalyst.

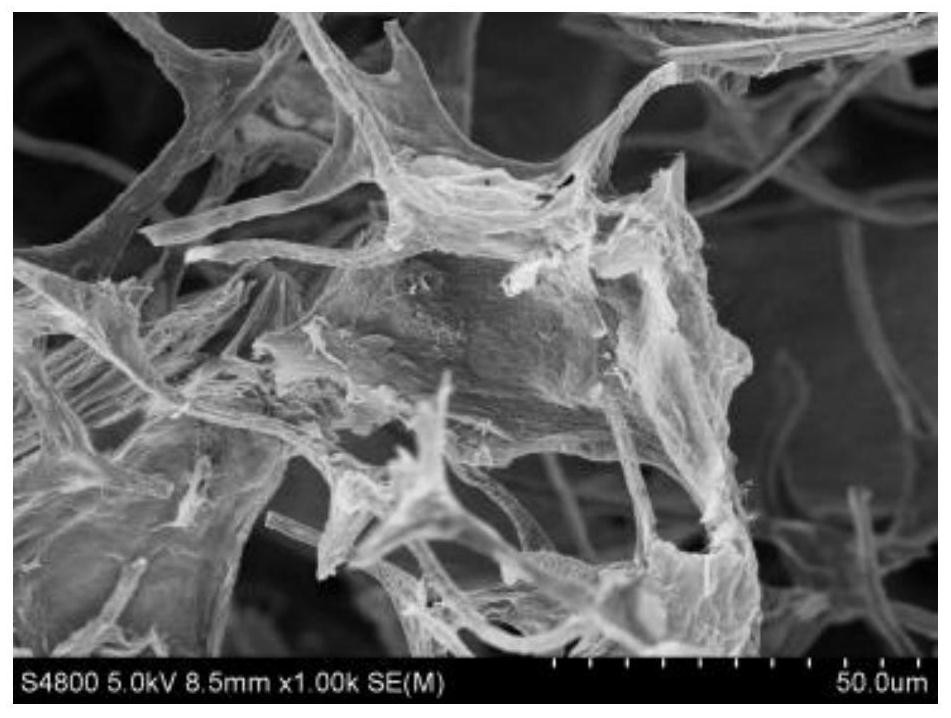

[0047] The ob...

Embodiment 2

[0058] Prepare foamy C in Example 1 3 N 4 The process of / GO@MF catalytic material is the same, only the concentration of urea in the precursor solution is 0 mg / mL.

[0059] Elemental analysis, scanning electron microscope (SEM) analysis, infrared spectrum analysis, Raman spectrum analysis, ultraviolet-visible diffuse reflectance absorption (UV-vis DRS) spectrum analysis, fluorescence spectrum analysis and photocatalytic activity test were carried out on the obtained samples respectively.

[0060] See Table 1 for the elemental analysis results, where it can be seen that the ratio of carbon to nitrogen in Example 2 is 5.42, indicating that the material is mainly carbon material and GO is successfully incorporated into the foam to increase the carbon-nitrogen ratio of the material.

[0061] Figure 2(b) is a scanning electron microscope (SEM) photo of the sample prepared in Example 2, as shown in Figure 2(b), indicating that GO in the sample prepared in Example 2 was successfull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com