Self-compacting expansive concrete

An expansive concrete and self-compacting technology, which is applied in the field of building materials, can solve the problems of large amount of cementitious materials and large shrinkage, and achieve the effects of widening the use range, enhanced functions, and a wide use temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

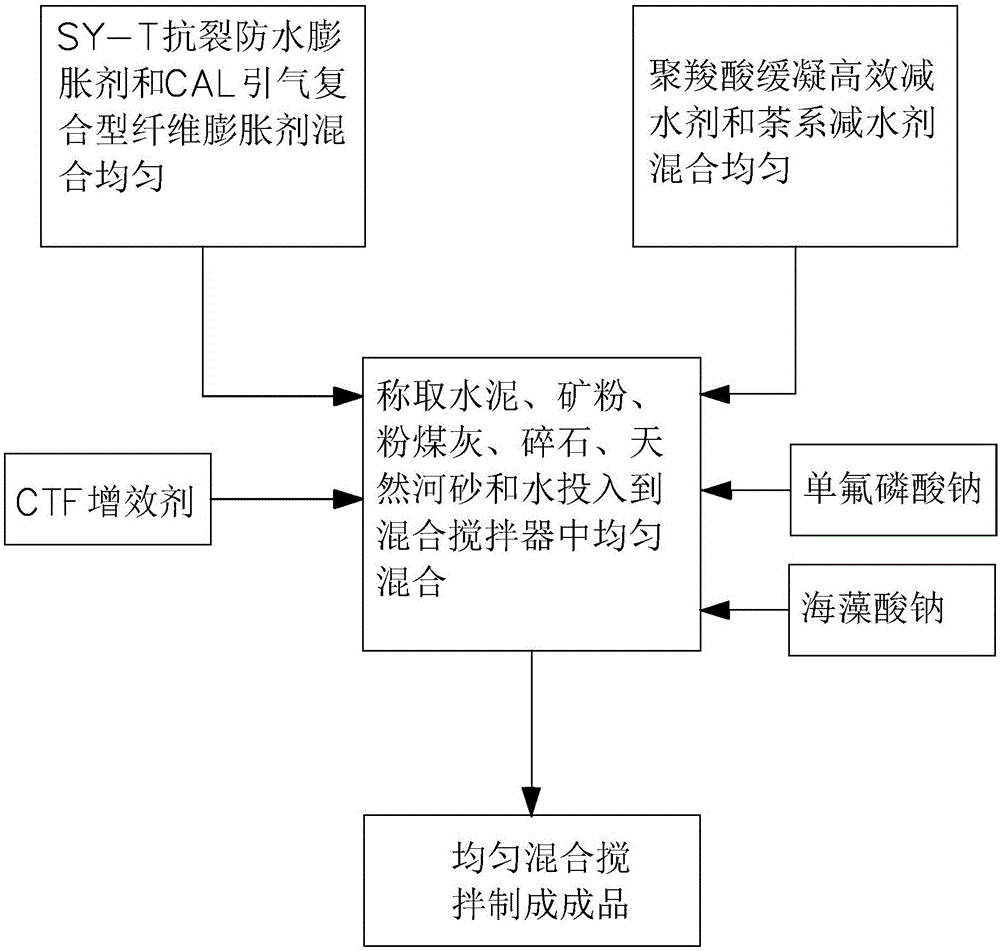

Method used

Image

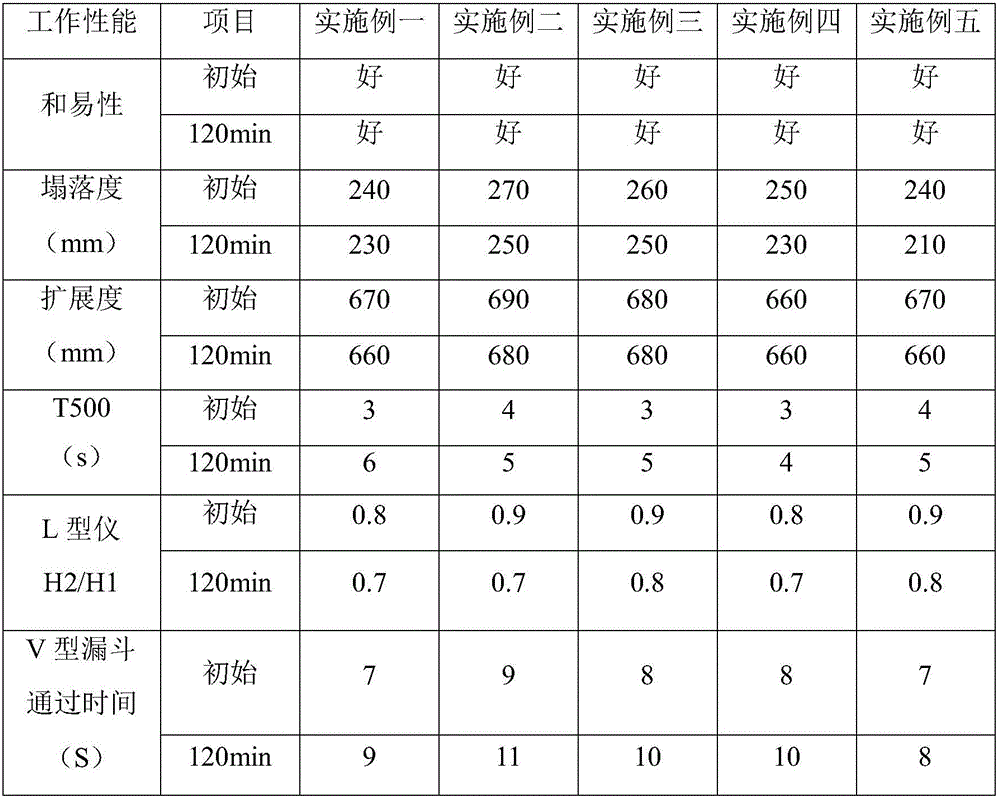

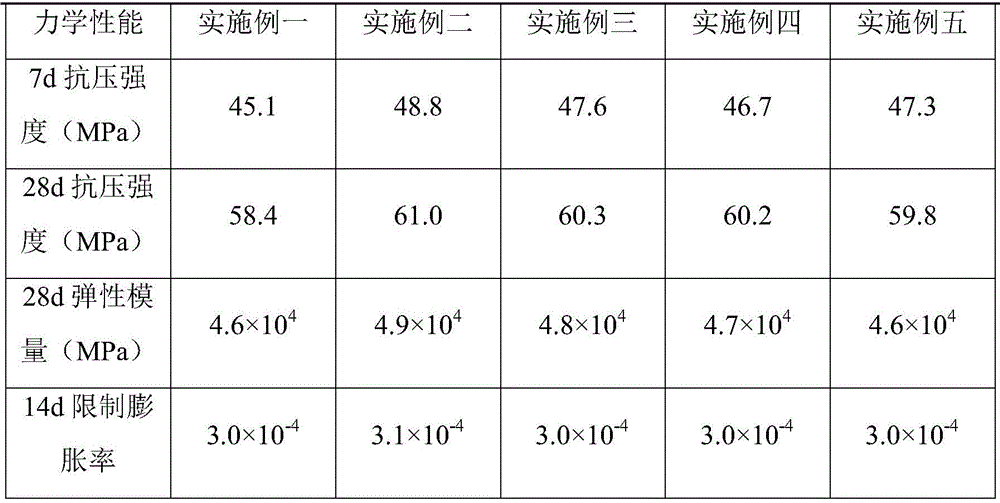

Examples

Embodiment 1

[0035] Step 1: Weigh 11.5kg of SY-T anti-crack and waterproof expansion agent and 11.5kg of CAL air-entraining composite fiber expansion agent and add them to the mixer for thorough mixing to prepare a mixed expansion agent for use as a spare;

[0036] Step 2: Weigh 4kg polycarboxylate retarding high-efficiency superplasticizer and 6kg tea-based superplasticizer and add them to the mixer for thorough mixing to prepare a mixed superplasticizer for use as a spare

[0037] Step 3: Weigh 340kg of cement, 80kg of mineral powder, 50kg of fly ash, 300kg of perlite crushed stone, 240kg of vermiculite crushed stone, 360kg of calcite crushed stone, 680kg of natural river sand and 350kg of water into the mixer, and Stir at a speed of 200rpm, and at the same time, add the mixed expansion agent and mixed water reducer in step 1 and step 2, and the stirring time is controlled at about 30min;

[0038] Step 4: Weigh 3kg of CTF synergist, 2.4kg of sodium monofluorophosphate and 2.8kg of sodium a...

Embodiment 2

[0041] Step 1: Weigh 11.6kg of SY-T anti-crack and waterproof expansion agent and 17.4kg of CAL air-entraining composite fiber expansion agent and add them to the mixer for thorough mixing to prepare a mixed expansion agent for use as a spare;

[0042] Step 2: Weigh 6.7kg of polycarboxylate retarding high-efficiency superplasticizer and 13.3kg of tea-based superplasticizer and add them to the mixer for thorough mixing to prepare a mixed superplasticizer for use as a spare

[0043] Step 3: Weigh 400kg of cement, 120kg of mineral powder, 70kg of fly ash, 275kg of perlite crushed stone, 385kg of vermiculite crushed stone, 440kg of calcite crushed stone, 760kg of natural river sand and 390kg of water into the mixer, and Stir at a speed of 200rpm, and at the same time, add the mixed expansion agent and mixed water reducer in step 1 and step 2, and the stirring time is controlled at about 30min;

[0044] Step 4: Weigh 3.4kg of CTF synergist, 2.8kg of sodium monofluorophosphate and 3...

Embodiment 3

[0047] Step 1: Weigh 11.3kg of SY-T anti-crack and waterproof expansion agent and 14.7kg of CAL air-entraining composite fiber expansion agent and add them to the mixer for thorough mixing to prepare a mixed expansion agent for use as a spare;

[0048] Step 2: Weigh 5.6kg of polycarboxylate retarding high-efficiency superplasticizer and 9.4kg of tea-based superplasticizer and add them to the mixer for thorough mixing to prepare a mixed superplasticizer for use as a spare

[0049] Step 3: Weigh 370kg of cement, 100kg of mineral powder, 60kg of fly ash, 285.7kg of perlite crushed stone, 314.3kg of vermiculite crushed stone, 400kg of calcite crushed stone, 720kg of natural river sand and 370kg of water into the mixer, Stir at a speed of 200 rpm, and at the same time, add the mixed expansion agent and mixed water reducer in step 1 and step 2, and the stirring time is controlled at about 30 minutes.

[0050] Step 4: Weigh 3.2kg of CTF synergist, 2.6kg of sodium monofluorophosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com