Acidic soil conditioner with straw as raw material, preparation method and application thereof

A soil conditioner and acidic soil technology, which is applied in the field of acidic soil conditioner and its preparation, can solve the problems that soil conditioner is difficult to be widely used, and achieve the effects of promoting the formation of soil aggregate structure, enhancing adsorption activity, and increasing alkali replacement capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

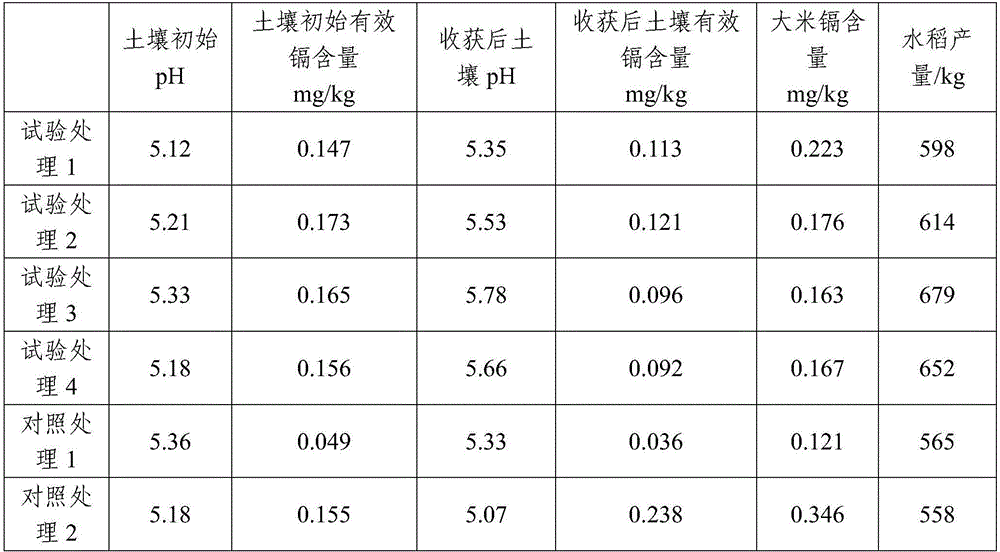

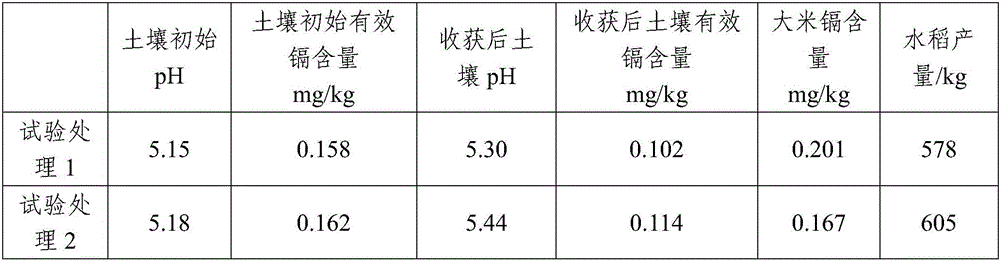

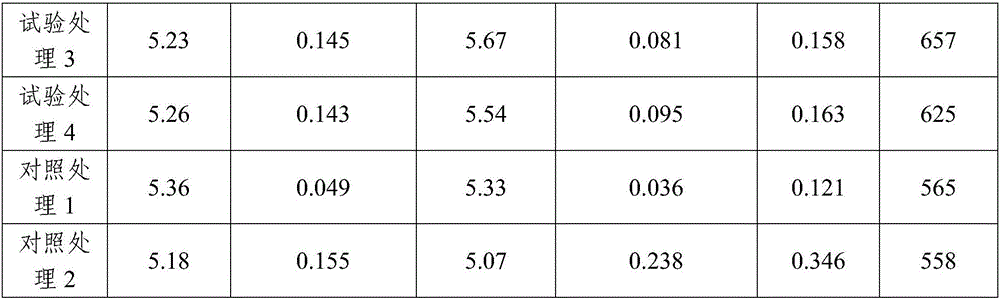

Examples

Embodiment 1

[0037] Embodiment 1 is the acidic soil conditioner with straw as raw material

[0038] (1) crushing straw raw materials to 16 meshes to obtain straw powder;

[0039] (2) Mix straw powder and attapulgite in a weight ratio of 50:20;

[0040] (3) Add the above mixture into lye solution containing 1.5% sodium hydroxide and 0.5% quicklime, the solid-to-liquid ratio is 10:100, heat to boiling, and keep for 30 minutes;

[0041] (4) Solid-liquid separation, drying the solid part to a water content≤30%;

[0042] (5) adding an appropriate amount of hydrochloric acid to the above liquid part to adjust the pH to neutral, and precipitating the lignin, and drying the solid part after solid-liquid separation until the water content is ≤ 30%;

[0043] (6) Mix the above two dried solid products with calcium magnesium phosphate fertilizer and ironmaking slag in a ratio of 70:10:20 to obtain a soil conditioner.

Embodiment 2

[0044] Embodiment 2 is the acidic soil conditioner with straw as raw material

[0045] (1) crushing straw raw materials to 16 meshes to obtain straw powder;

[0046] (2) Mix straw powder and attapulgite in a weight ratio of 60:20;

[0047] (3) Add the above mixture into lye solution containing 1.5% sodium hydroxide and 0.5% quicklime, the solid-to-liquid ratio is 10:100, heat to boiling, and keep for 30 minutes;

[0048] (4) Solid-liquid separation, drying the solid part to a water content≤30%;

[0049] (5) adding an appropriate amount of hydrochloric acid to the above liquid part to adjust the pH to neutral, and precipitating the lignin, and drying the solid part after solid-liquid separation until the water content is ≤ 30%;

[0050] (6) Mix the above two dried solid products with calcium magnesium phosphate fertilizer and ironmaking slag at a ratio of 80:10:10 to obtain a soil conditioner.

Embodiment 3

[0051] Embodiment 3 is the acidic soil conditioner with straw as raw material

[0052](1) crushing straw raw materials to 16 meshes to obtain straw powder;

[0053] (2) Mix straw powder and attapulgite in a weight ratio of 40:20;

[0054] (3) Add the above mixture into lye solution containing 1.5% sodium hydroxide and 0.5% quicklime, the solid-to-liquid ratio is 10:100, heat to boiling, and keep for 35 minutes;

[0055] (4) Solid-liquid separation, drying the solid part to a water content≤30%;

[0056] (5) adding an appropriate amount of hydrochloric acid to the above liquid part to adjust the pH to neutral, and precipitating the lignin, and drying the solid part after solid-liquid separation until the water content is ≤ 30%;

[0057] (6) Mix the above two dried solid products with calcium magnesium phosphate fertilizer and ironmaking slag in a ratio of 60:15:25 to obtain a soil conditioner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com