Lubricating oil containing nitrogen boric acid ester additive and preparation method thereof

A nitrogen borate and additive technology, applied in the field of lubricating oil, can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simple preparation method and reduced mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

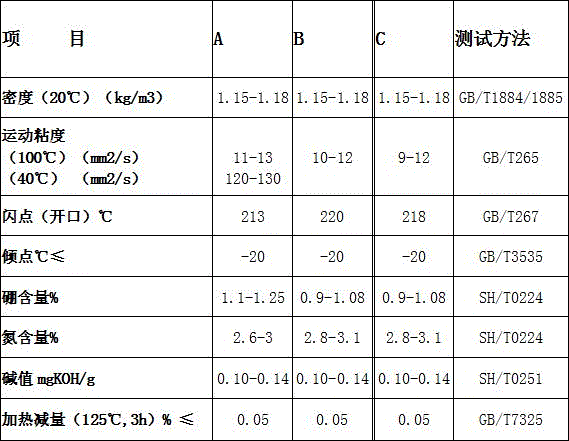

Embodiment 1

[0021] A lubricating oil containing a nitrogen borate additive is prepared by the following method: in a reaction kettle with a stirrer, a thermometer and a water separation and reflux device, adding boric acid and hexadecanoic acid with a molar ratio of 1: 1.5 Alcohol, and add a certain amount of toluene as a solvent, stir and react at about 120 ° C for 1 hour, then add ethanolamine with a molar ratio of 3, react for 5 hours, and reflux to obtain nitrogen borate lubricating oil additive;

[0022] Add 1% of the above-mentioned nitrogen borate additive (mass percentage, the same below), 8% of thiophosphatyl octyl zinc salt, 30% of petroleum ether, 10% of sorbitol, 20% of glycerin, 20% of cyclohexane, fluorine Surfactant 1% and borated polyisobutenyl succinimide 10% were stirred and blended to prepare "lubricating oil A".

Embodiment 2

[0024] A lubricating oil containing a nitrogen borate additive is prepared by the following method: in a reaction kettle with a stirrer, a thermometer and a water separation and reflux device, adding boric acid and hexadecanoic acid in a molar ratio of 1:2 Alcohol, and add a certain amount of toluene as a solvent, stir and react at about 120 ° C for 1 hour, then add ethanolamine with a molar ratio of 3, react for 5 hours, and reflux to obtain nitrogen borate lubricating oil additive;

[0025] Add 3% of the above-mentioned nitrogen borate additive (mass percentage, the same below), 5% of octyl zinc salt of thionate, 25% of petroleum ether, 15% of sorbitol, 15% of glycerin, 25% of cyclohexane, fluorine Surfactant 2% and borated polyisobutenyl succinimide 10% were stirred and blended to prepare "lubricating oil B".

Embodiment 3

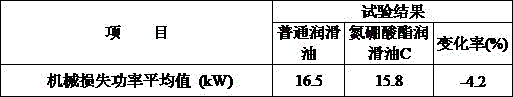

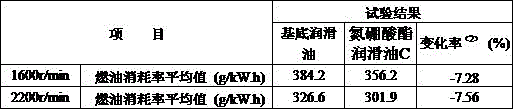

[0027] A lubricating oil containing a nitrogen borate additive is prepared by the following method: in a reaction kettle with a stirrer, a thermometer and a water separation and reflux device, adding boric acid and hexadecanoic acid with a molar ratio of 1: 1.5 Alcohol, and add a certain amount of toluene as a solvent, stir and react at about 120 ° C for 1 hour, then add ethanolamine with a molar ratio of 5, react for 5 hours, and reflux to obtain nitrogen borate lubricating oil additive;

[0028] Add 5% of the above-mentioned nitrogen borate additive (mass percentage, the same below), 6% of octyl zinc salt of thionate, 25% of petroleum ether, 15% of sorbitol, 15% of glycerin, 25% of cyclohexane, fluorine Surfactant 1% and borated polyisobutenyl succinimide 8% were stirred and blended to prepare "lubricating oil C".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com