Method for performing deacidification reinforcement on paper cultural relic by one-step process

A paper cultural relic and deacidification technology, applied in the post-processing of waste paper, etc., can solve the problems of paper aging, cumbersome implementation, strict requirements, etc., to prevent the growth of mold, facilitate the later preservation, and strengthen the effect of paper cultural relics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

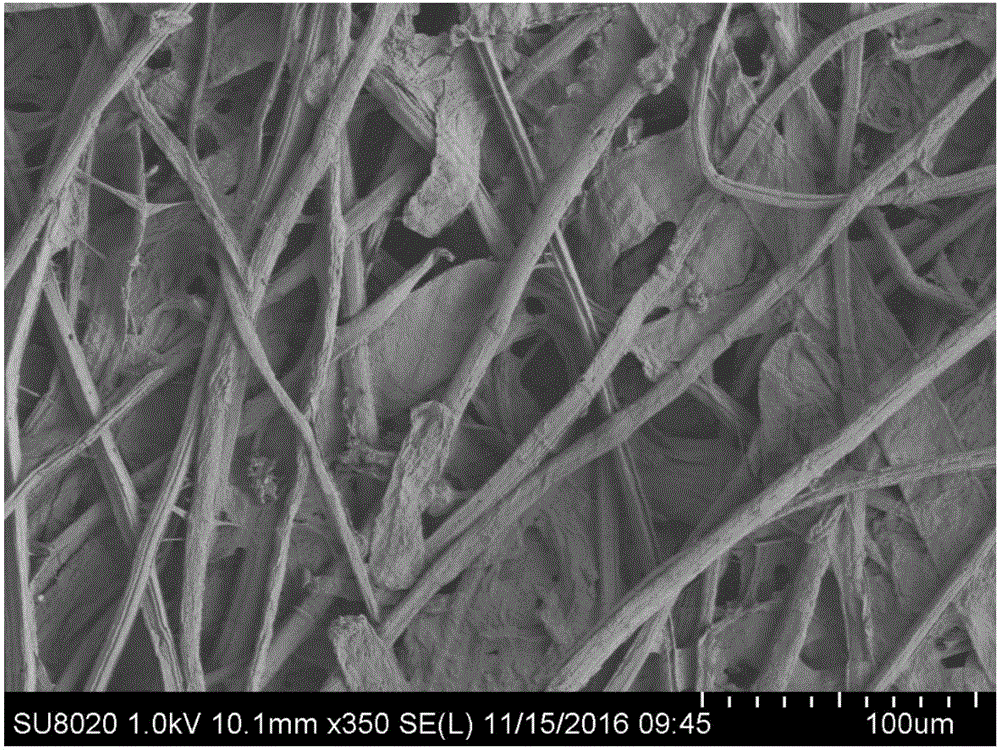

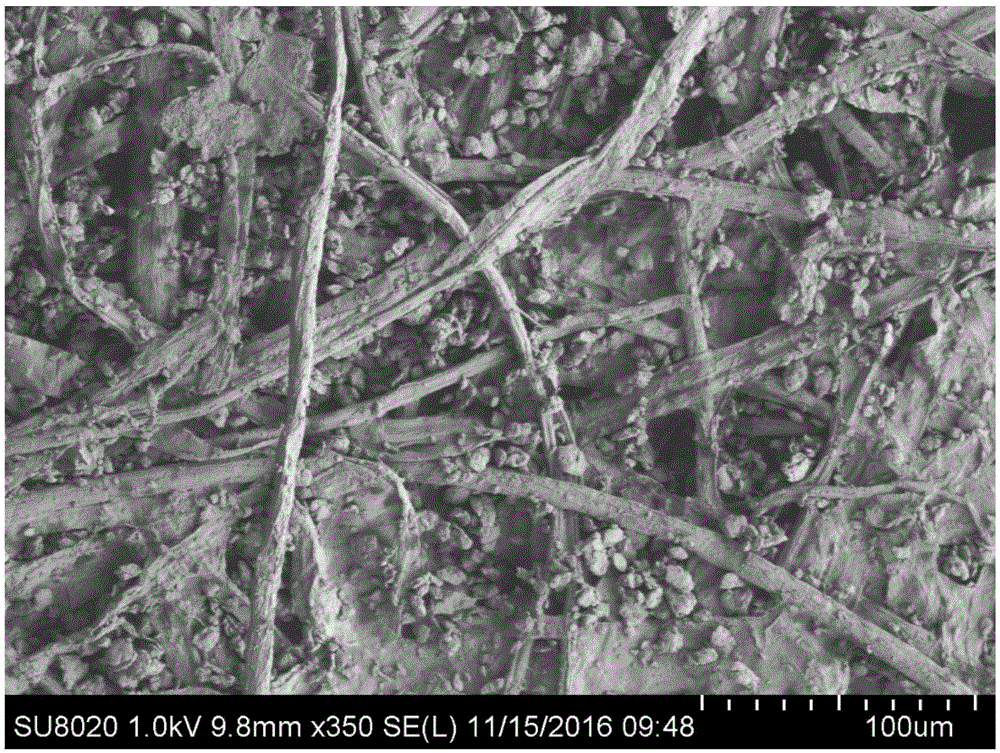

Embodiment 1

[0019] Chitosan with a degree of deacetylation of 91.5% is placed in a ball mill jar, and zirconia balls with a diameter of 5 mm are used as grinding balls, fully ball-milled for 24 hours with a QM-3SP2 planetary ball mill at 401 rpm, and the zirconia balls are separated. To obtain chitosan with a particle size less than 10 μm; 1.5 g of the gained chitosan was added in 100 mL of isopropanol, and ultrasonically dispersed at room temperature for 30 minutes to uniformly disperse the chitosan, and the concentration of chitosan in the gained milky white dispersion was 15 mg / mL. Spray the obtained dispersion evenly on the acidic paper cultural relics with a spray gun, and let it dry naturally.

Embodiment 2

[0021] Chitosan with a degree of deacetylation of 91.5% is placed in a ball mill jar, and zirconia balls with a diameter of 5 mm are used as grinding balls, fully ball-milled for 24 hours with a QM-3SP2 planetary ball mill at 401 rpm, and the zirconia balls are separated. To obtain chitosan with a particle size of less than 20 μm; add 1 g of the obtained chitosan to 100 mL of isopropanol, and disperse it ultrasonically for 30 minutes at room temperature to disperse the chitosan evenly, and the concentration of chitosan in the obtained milky white dispersion is 10 mg / mL . Spray the obtained dispersion evenly on the acidic paper cultural relics with a spray gun, and let it dry naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com