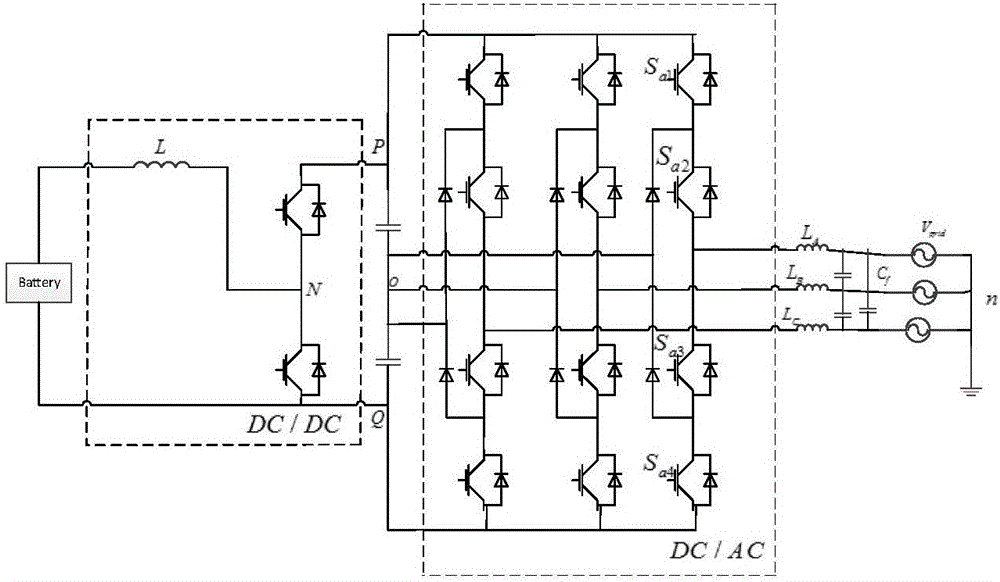

Non-isolation type three-phase three-level V2G charge-discharge topological structure and control method therefor

A topology, three-level technology, used in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of large common-mode voltage, difficult to find, etc., to suppress spikes, reduce switching times, and ensure The effect of the energy bidirectional flow characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

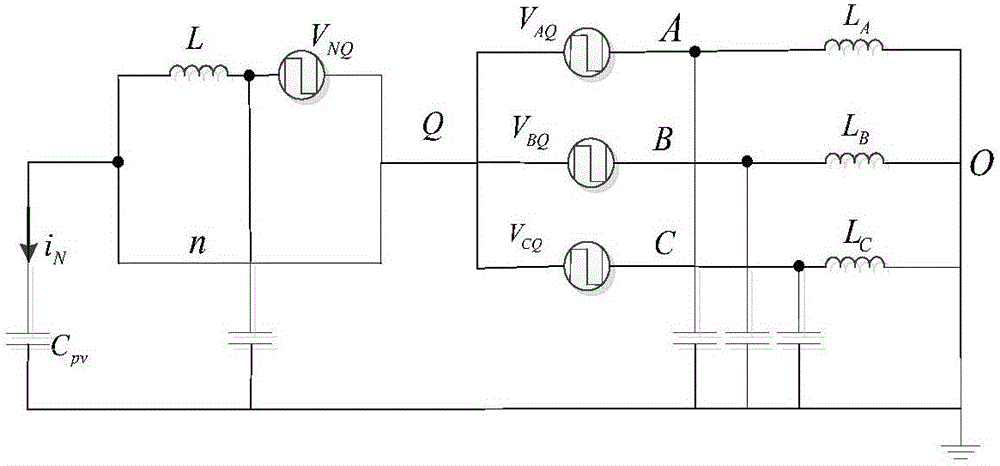

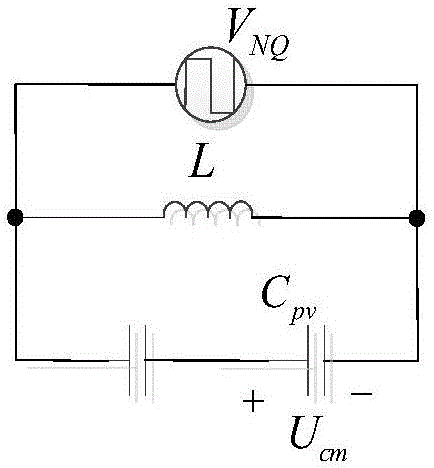

[0047] The logical relationship of the control strategy is as follows Figure 5 shown. The details are as follows: Let the electromotive force of the three-phase grid be e a ,e b ,e c , connected to the connection of the upper and lower arms of each phase bridge arm through the three-phase linear inductance L, the currents of the three-phase grid side are respectively i a ,i b ,i c , the AC / DC part adopts the double closed-loop control structure of the voltage outer loop and the current inner loop, the reference voltage vector signal is obtained through the double closed loop, and sent to the SVPWM control module to generate twelve control pulses, which are sent to the AC / DC part twelve switch tube, the control strategy of the present invention proposes at the SVPWM control module (see Figure 5 The SVPWM signal generation module in).

[0048] from Image 6 It can be seen that the ordered letter combination composed of P, O and N represents 27 groups of switch states, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com