Micro/nano-structure rod-like Bi2O3 photocatalytic material and preparation method thereof

A technology of photocatalytic materials and micro-nano structures, applied in chemical instruments and methods, physical/chemical process catalysts, water/sludge/sewage treatment, etc., can solve the problem of large nano-powder size, limited adsorption performance, and low specific surface area and other problems, to achieve good dispersion and separation characteristics, improve reusability, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

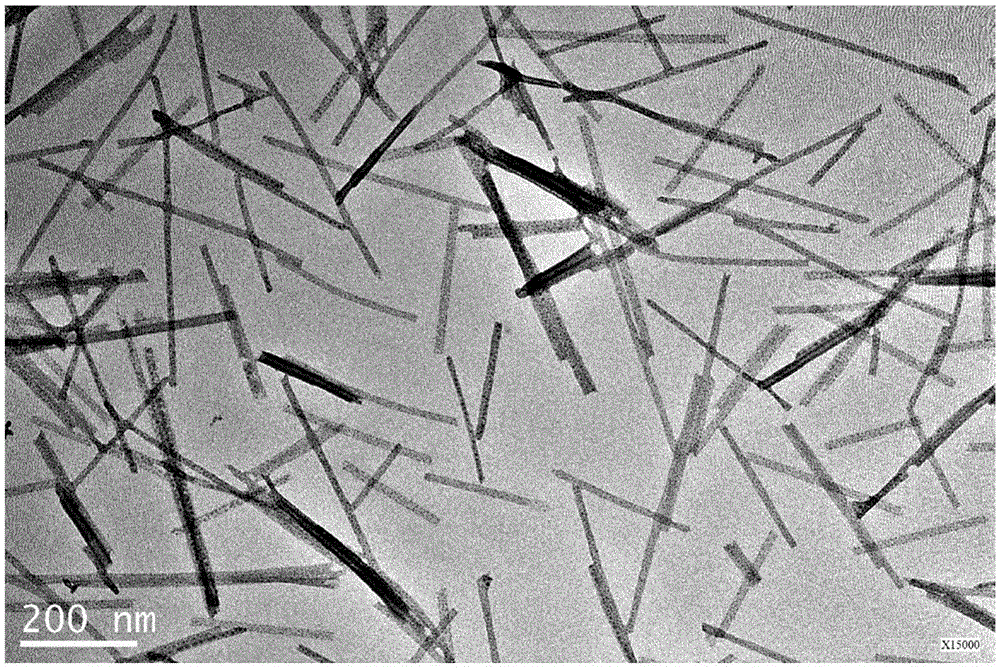

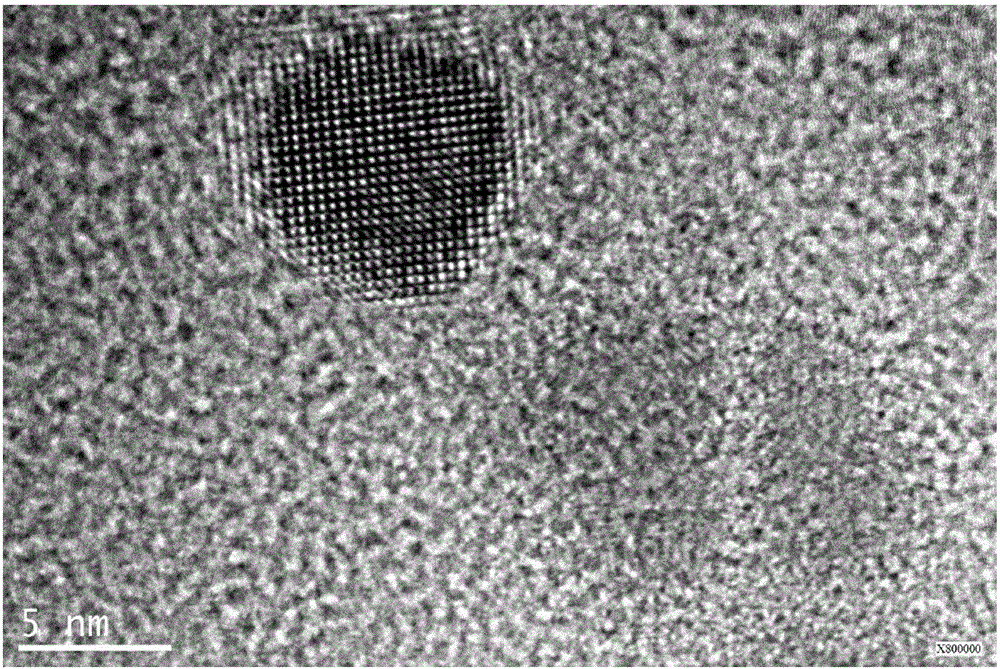

[0023] A rod-shaped Bi with micro-nano structure 2 o 3 The preparation method of photocatalytic material, concrete steps are as follows:

[0024] (1) 8mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20mL concentration of 0.1M mannitol aqueous solution, completely dissolved to obtain bismuth nitrate solution for subsequent use;

[0025] (2) the configuration concentration is an aqueous solution of Planckney F-127 of 1 mM;

[0026] (3) Under ultrasonic conditions, slowly add the Planckney F-127 aqueous solution to the bismuth nitrate solution, and after the addition is completed, continue ultrasonication for 10 minutes to form a mixed solution I;

[0027] (4) Under ultrasonic conditions, add 0.1M ascorbic acid solution to the mixed solution I to form Bi 3+ For the mixed solution II with a concentration of 0.01M, the mixed solution II was continuously ultrasonicated for 1 hour, then allowed to stand for 10 hours, fully reacted to form a light yellow precipitate, washed with deion...

Embodiment 2

[0032] The preparation method of this embodiment is the same as that of Example 1, except that the solvent of the bismuth nitrate solution in step (1) is modified from 20 mL of 0.1 M mannitol aqueous solution to 20 mL of 0.1 M ethylene glycol.

[0033] Rod-shaped Bi prepared by this process 2 o 3 The photocatalytic material has a diameter of about 40nm and a length of about 1μm. It has a strong adsorption capacity. The adsorption rate of 40mg / L methyl orange within 30min is 96.2%, and the degradation rate of 20mg / L methyl orange under visible light is 60%.

Embodiment 3

[0035] The preparation method of the present embodiment is the same as that of Example 1, except that Bi(NO 3 ) 3 ·5H 2 The amount of O added was changed from 8mmol to 16mmol.

[0036] Rod-shaped Bi prepared by this process 2 o 3 The photocatalytic material has a diameter of about 40nm and a length of about 1μm. It has a strong adsorption capacity. The adsorption rate of 40mg / L methyl orange within 30min is 93.2%, and the degradation rate of 20mg / L methyl orange under visible light is about 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com