Production technology of nano-CuS

A production process and nanotechnology, applied in the field of lubricating oil, can solve problems such as poor dispersion performance, environmental pollution, restricted application, etc., and achieve the effect of improving performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

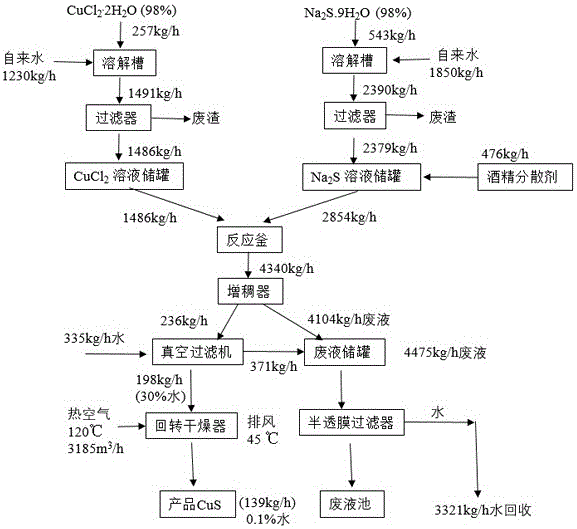

Image

Examples

Embodiment 1

[0027] A production process of nano-copper sulfide, comprising the following steps:

[0028] (1) Put 98% CuCl at a speed of 257kg / h 2 .2H 2 O is added to the dissolution tank, and after adding water to dissolve at a speed of 1230kg / h, the solution flows into the filter at a speed of 1491kg / h to remove waste residue, and the filtrate flows into CuCl at a speed of 1486kg / h 2 Standby in the solution storage tank;

[0029] (2) 98% Na at a rate of 543kg / h 2 S.9H 2 O is added to the dissolution tank, and after adding water to dissolve at a speed of 1850kg / h, the solution flows into the filter at a speed of 2390kg / h to remove waste residue, and the filtrate flows into Na at a speed of 2379kg / h. 2 In the S solution storage tank, add alcohol at a rate of 476kg / h to disperse evenly and set aside;

[0030] (3) CuCl 2 solution and Na 2 The S solution flows into the reactor at the speed of 1486kg / h and 2854kg / h, and after 20 minutes of reaction, it enters the thickener at the speed ...

Embodiment 2

[0034] (1) Put 98% CuCl at a speed of 240kg / h 2 .2H 2 O is added to the dissolution tank, and after adding water to dissolve at a rate of 1220kg / h, the solution flows into the filter at a rate of 1480kg / h to remove waste residue, and the filter flows into CuCl at a rate of 1470kg / h 2 Standby in the solution storage tank;

[0035] (2) 98% Na at a rate of 530g / h 2 S.9H 2 O is added to the dissolution tank, and after adding water to dissolve at a speed of 1840kg / h, the solution flows into the filter at a speed of 2350kg / h to remove waste residue, and the filtrate flows into Na at a speed of 2350kg / h. 2 In the S solution storage tank, add alcohol at a rate of 460kg / h to disperse evenly and set aside;

[0036] (3) CuCl 2 solution and Na 2 The S solution flows into the reactor at the speed of 1480kg / h and 2840kg / h, and after 25 minutes of reaction, it enters the thickener at the speed of 4320kg / h;

[0037] (4) After being thickened by the thickener, the waste liquid flows int...

Embodiment 3

[0040] (1) Put 98% CuCl at a speed of 260kg / h 2 .2H 2 O is added to the dissolution tank, and after adding water to dissolve at a rate of 1250kg / h, the solution flows into the filter at a rate of 1500kg / h to remove waste residue, and the filter flows into CuCl at a rate of 1490kg / h 2 Standby in the solution storage tank;

[0041] (2) 98% Na at a rate of 550g / h 2 S.9H 2 O is added to the dissolution tank, and after adding water to dissolve at a rate of 1860kg / h, the solution flows into the filter at a rate of 2400kg / h to remove waste residue, and the filtrate flows into Na at a rate of 2390kg / h. 2 In the S solution storage tank, add alcohol at a rate of 480kg / h to disperse evenly and set aside;

[0042] (3) CuCl 2 solution and Na 2 The S solution flows into the reactor at the speed of 1500kg / h and 2860kg / h, and after 30 minutes of reaction, it enters the thickener at the speed of 4360kg / h;

[0043] (4) After being thickened by the thickener, the waste liquid flows into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com