Method for preparing nano hydroxyl manganese cobalt oxide

A cobalt manganese oxide and manganese cobalt oxide technology, applied in the field of nanomaterials, can solve problems such as being unfavorable to mass production, poor product stability, uneven reaction, etc., and achieve the effects of low cost, stable product quality, and good process repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing nanometer cobalt-manganese oxyhydroxides of the present invention comprises the following steps:

[0025] (1) Manganese acetate tetrahydrate and cobalt acetate tetrahydrate are dissolved in 200mL of deionized water, and the concentration of the prepared manganese acetate and cobalt acetate is 0.0125mol / L in the mixed solution;

[0026] (2) Utilize dilute sulfuric acid to adjust the pH value of the mixed solution to 2.5;

[0027] (3) At 35° C., pass ozone into the mixed solution treated in step (2), react for 1 hour, then centrifuge, wash, and finally dry at 80° C. to obtain a nanometer cobalt-manganese oxyhydroxide product.

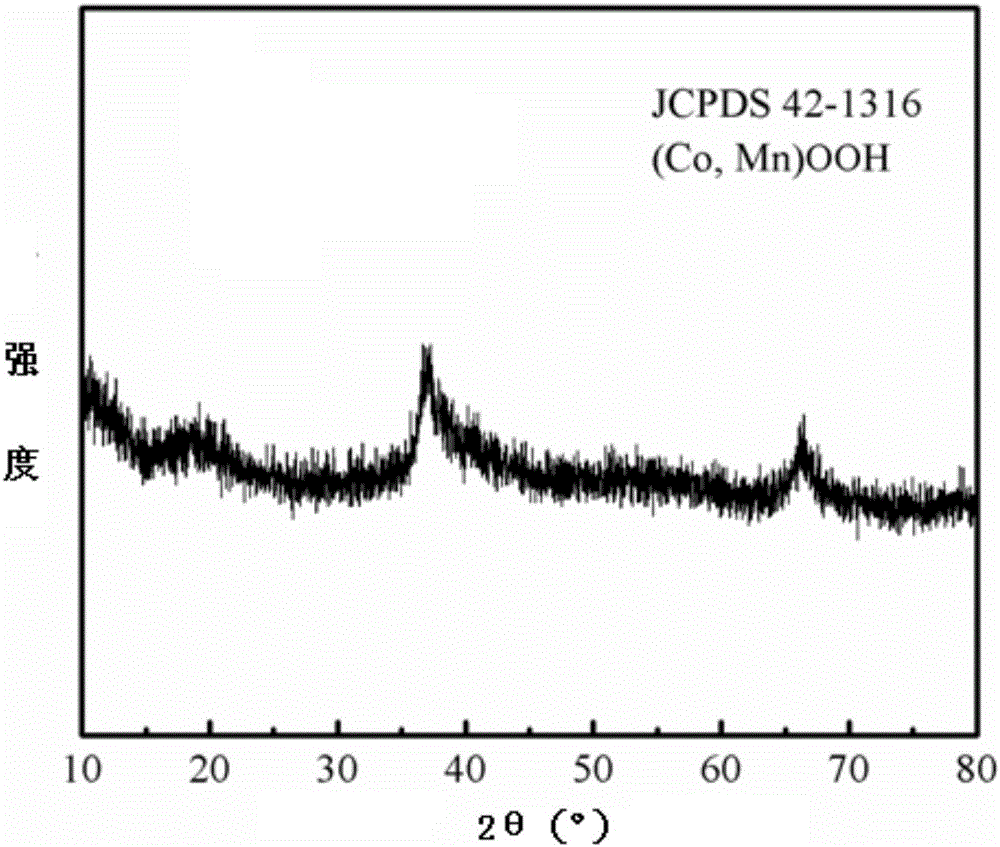

[0028] The XRD pattern of the nanometer cobalt-manganese oxyhydroxide product prepared in this embodiment is as follows figure 1 Shown, show that product is cobalt manganese oxyhydroxide, and chemical formula is (Co a ,Mn 1-a )OOH, the standard card number is JCPDS 42-1316; the nano cobalt-manganese oxyhydroxide prepared i...

Embodiment 2

[0031] A method for preparing nanometer cobalt-manganese oxyhydroxides of the present invention comprises the following steps:

[0032] (1) Manganese acetate tetrahydrate and cobalt acetate tetrahydrate are dissolved in 200mL of deionized water, and the concentration of the prepared manganese acetate and cobalt acetate is 0.0125mol / L in the mixed solution;

[0033] (2) Utilize dilute sulfuric acid to adjust the pH value of the mixed solution to 3.5;

[0034] (3) At 35° C., pass ozone into the mixed solution treated in step (2), react for 45 minutes, then centrifuge, wash, and finally dry at 80° C. to obtain nanometer cobalt-manganese oxyhydroxide products.

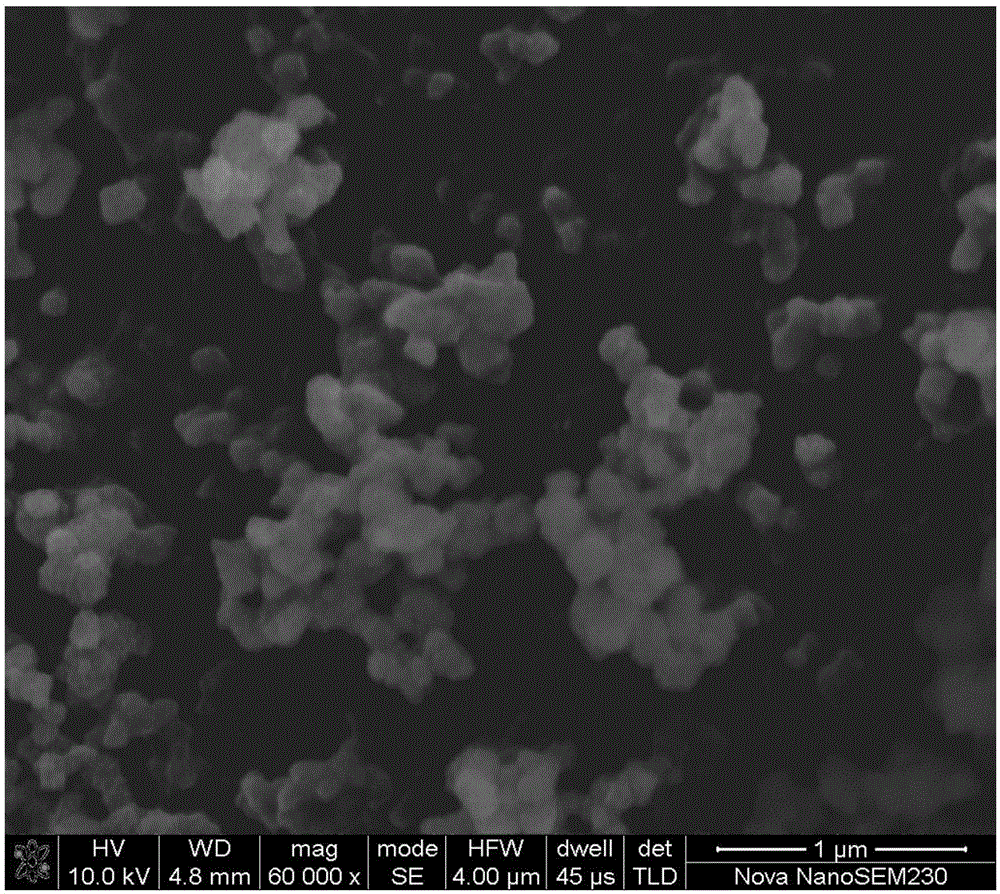

[0035] The FESEM figure of the nano cobalt-manganese oxyhydroxide product prepared by the present embodiment is as follows figure 2 As shown, as can be seen from the figure, the nano-cobalt-manganese oxyhydroxide prepared in this embodiment is spherical, and the particle size is about 200nm; through XRD and XPS detection...

Embodiment 3

[0037] A method for preparing nanometer cobalt-manganese oxyhydroxides of the present invention comprises the following steps:

[0038] (1) Manganese acetate tetrahydrate and cobalt acetate tetrahydrate are dissolved in 200mL deionized water, and the manganese acetate and cobalt acetate mixed solution (concentration of manganese acetate in the mixed solution is 0.0125mol / L, and the concentration of cobalt acetate is 0.025mol / L);

[0039] (2) Utilize dilute sulfuric acid to adjust the pH value of the mixed solution to 2.5;

[0040] (3) At 70° C., pass ozone into the mixed solution treated in step (2), react for 1 hour, then centrifuge, wash, and finally dry at 80° C. to obtain nanometer cobalt-manganese oxyhydroxide products. The nano cobalt manganese oxyhydroxide prepared in this embodiment is spherical, and the particle diameter is about 123nm; Through XRD and XPS detection, show that the chemical formula of the nano cobalt manganese oxyhydroxide product of this embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com