Preparation method of ramie bone cellulose nanocrystalline self-assembled structural color thin film

A technology of ramie bone and cellulose, which is applied in the field of preparation of ramie bone cellulose nanocrystalline self-assembled structural color film, can solve the problems of complicated process steps and the inability to control the size of cellulose nanocrystals, and solve the problem of environmental pollution , Improve the value of comprehensive utilization and the effect of rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a ramie bone cellulose nanocrystalline self-assembled structural color film, comprising the following steps:

[0032] (1) mixing ramie bone cellulose with sulfuric acid, carrying out a hydrolysis reaction, to obtain a reaction solution containing ramie bone nanocrystalline cellulose;

[0033] (2) the reaction solution obtained in the step (1) is subjected to centrifugation and dialysis to obtain ramie bone nanocrystalline cellulose suspension;

[0034] (3) The solvent in the ramie bone nanocrystalline cellulose suspension obtained in the step (2) is removed to obtain the ramie bone cellulose nanocrystalline self-assembled structural color film.

[0035] Ramie bone cellulose in the present invention preferably obtains through the following steps:

[0036] Mixing ramie bone meal with water and performing steam explosion treatment;

[0037] mixing the treated ramie bone powder with sodium hydroxide, and cooking to obtain rami...

Embodiment 1

[0053] Take 100g of ramie bone powder, add 500mL of distilled water, and steam explosion at 121°C for 20min. Take 50g of pretreated ramie bone meal, add 1500mL of 10% NaOH solution, cook at 75°C for 6h, let it stand for 12h, filter with suction, soak the filter residue in 200mL distilled water for 2h, filter, repeat the operation 3 times, and dry the filter residue dry to obtain ramie bone crude cellulose; take 30g ramie bone crude cellulose, add 750mL 5% H in a water bath at 55°C 2 o 2 React for 8 hours, then filter, rinse the filter residue with distilled water three times, and dry the obtained ramie bone cellulose.

Embodiment 2

[0055] Take 2.0 g of the ramie bone cellulose prepared in Example 1, add 20 mL of 68% sulfuric acid, and react with magnetic stirring at 55° C. for 35 minutes. The stirring speed is controlled at 700 rpm. Treat for 10 minutes, remove the supernatant, wash the precipitate with an equal amount of distilled water, repeat the above centrifugation and washing operations 5 times, transfer the obtained suspension to a dialysis bag for dialysis, and end the dialysis when the pH of the dialysate is 7 to obtain nanocrystals For the cellulose suspension, take the above-mentioned cellulose suspension and place it in a plate, and evaporate the solvent at room temperature to obtain a ramie bone cellulose nanocrystalline self-assembled structural color film.

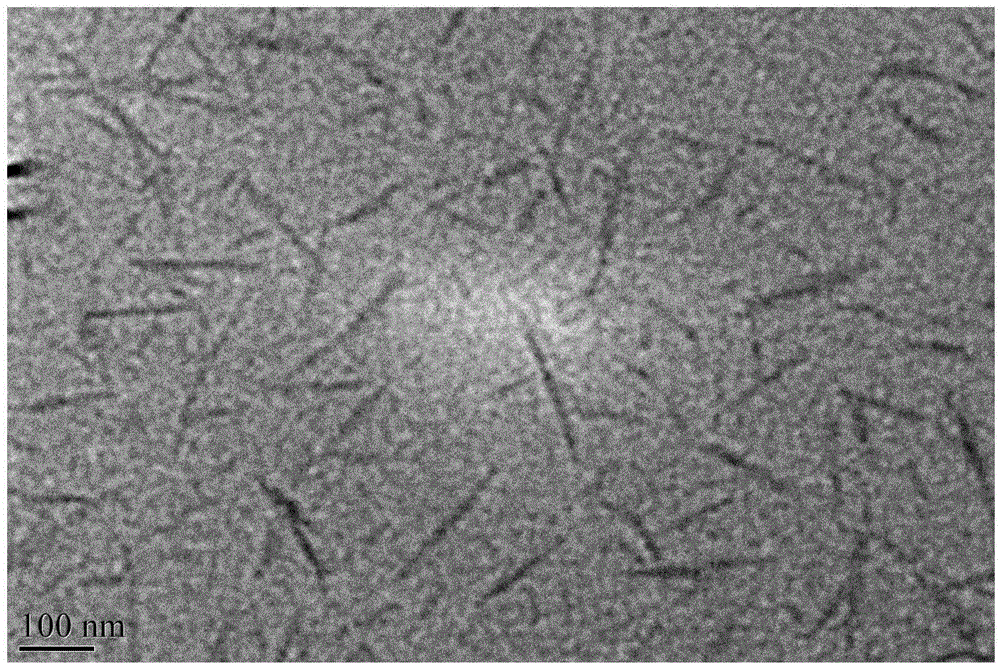

[0056] Using a transmission electron microscope to detect the size of the nanocrystalline cellulose, the size of the nanocrystalline cellulose can be obtained as 5±0.4nm×180±6nm (diameter×length);

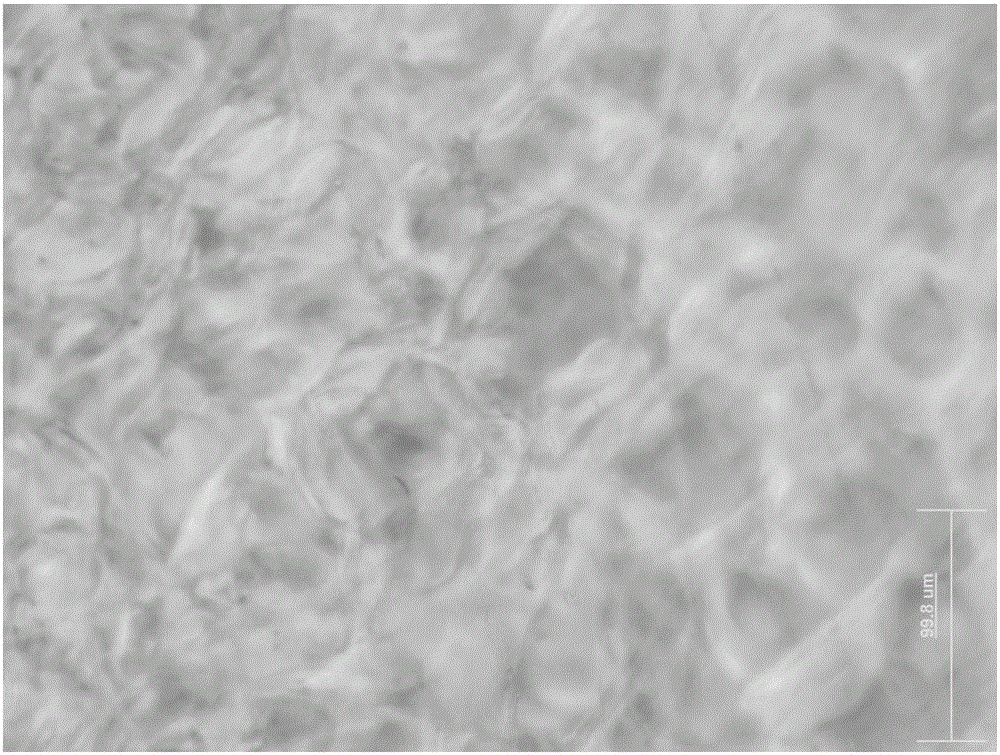

[0057] Using a polarizing microscope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com