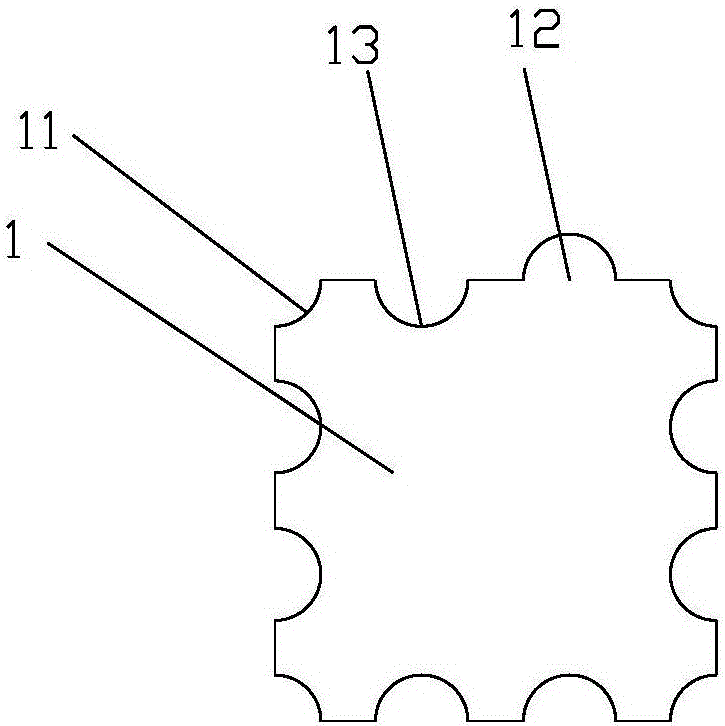

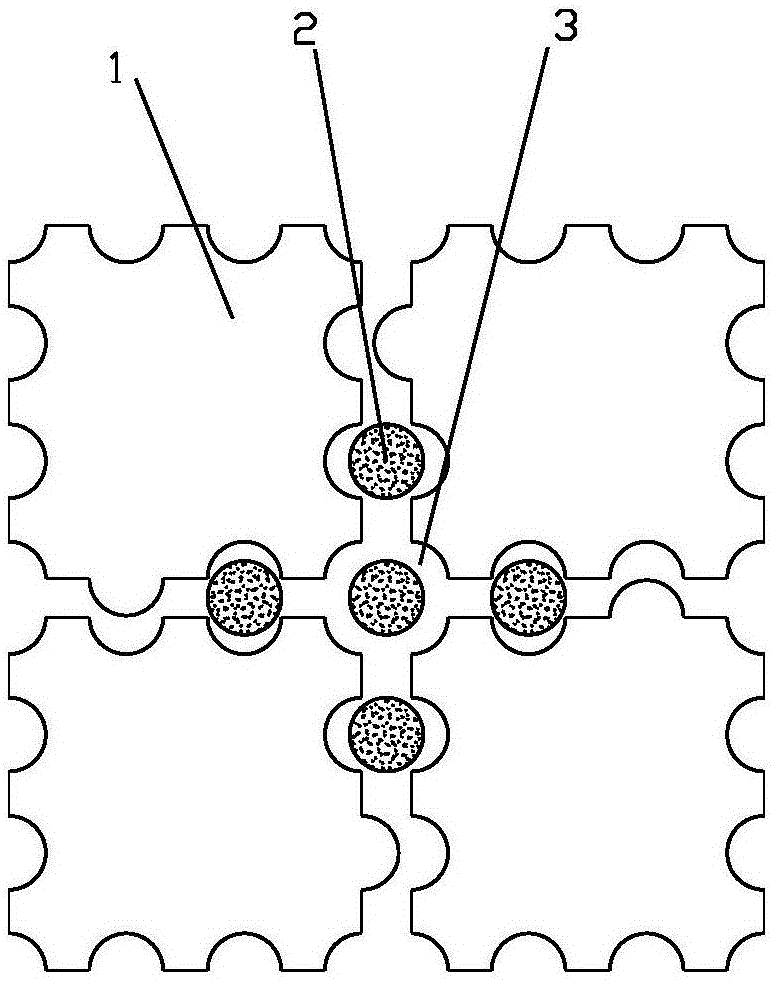

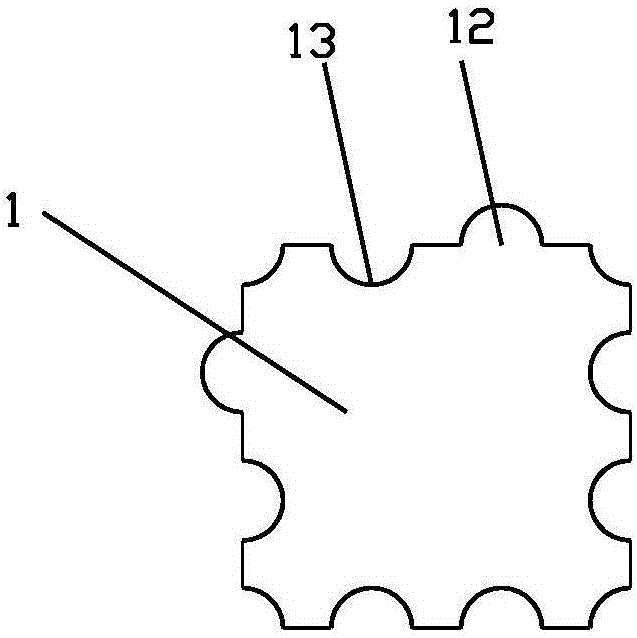

Concrete water-permeable road surface as well as paving method thereof and maintenance and restoration method thereof

A technology for permeable pavement and concrete, applied in road repair, pavement, road, etc., can solve the problems of water shortage, water environment pollution, water ecology deterioration, etc., to ensure physical and mechanical properties and durability, ensure water permeability, avoid The effect of dislocation deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The base layer is prepared from aggregates with larger particle sizes, including 18% cement, 52% stones with a particle size of 5-8mm, 27% stones with a particle size of 8-10mm and 3% additives in weight percentage ; Additives used in the base layer include silica fume 2.0%, acrylic acid emulsion 0.8%, polycarboxylate superplasticizer 0.2%.

[0046] The surface layer is made of aggregates with smaller particle sizes, including 20% cement, 45% quartz sand with a particle size of 1-2mm, 30% stones with a particle size of 2.5-3.5mm, 1.5% pigment and 3.5% additives; the additives used in the surface layer include 1.7% silica fume, 1.6% acrylic emulsion, and 0.2% polycarboxylate superplasticizer.

[0047] The water permeability coefficient of the permeable concrete pavement brick of the invention is more than or equal to 0.4mm / s, the flexural strength reaches more than or equal to 5.0 MPa, and the frost resistance (25 times) is qualified.

Embodiment 2

[0048] Embodiment 2: The base layer is prepared from aggregates with larger particle sizes, including 15% cement, 43% stones with a particle size of 5-8mm, 40% stones with a particle size of 8-10mm and 2% additives in weight percentage ; Additives used in the base layer include silica fume 1.0%, acrylic acid emulsion 0.8%, polycarboxylate superplasticizer 0.2%.

[0049] The surface layer is made of aggregates with smaller particle sizes, including 15% cement, 40% quartz sand with a particle size of 1-2mm, 40% stones with a particle size of 2.5-3.5mm, 1.5% pigment and 3.5% additives; the additives used in the surface layer include 2.0% silica fume, 1.3% acrylic emulsion, and 0.2% polycarboxylate superplasticizer.

[0050] The permeable concrete pavement brick of the invention has a water permeability coefficient of ≥0.3mm / s and a flexural strength of ≥4.0MPa.

Embodiment 3

[0051] Embodiment 3: The base layer is prepared from aggregates with larger particle sizes, including 20% cement, 56% stones with a particle size of 5-8mm, 20% stones with a particle size of 8-10mm and 4% additives in weight percentage ; Additives used in the base layer include silica fume 2.0%, acrylic acid emulsion 1.8%, polycarboxylate superplasticizer 0.2%.

[0052] The surface layer is made of aggregates with smaller particle sizes, including 18% cement, 48% quartz sand with a particle size of 1-2mm, 30% stones with a particle size of 2.5-3.5mm, 1.5% pigment and 2.5% additives; the additives used in the surface layer include 1.5% silica fume, 0.8% acrylic emulsion, and 0.2% polycarboxylic acid superplasticizer.

[0053] The water permeability coefficient of the permeable concrete pavement brick of the invention is ≥0.35mm / s, and the flexural strength reaches ≥4.5MPa.

[0054] The additives used in the base layer and the surface layer include active mixed material, poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com