Boiler waste heat recycling and steam temperature control system

A steam temperature control, boiler technology, applied in the direction of superheated temperature control, steam superheating, steam generation, etc., can solve the problems of insensitive adjustment of the main steam temperature of the boiler, large temperature difference, insensitive adjustment, etc., to solve the problem of superheater explosion Tube and desuperheater damage, life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

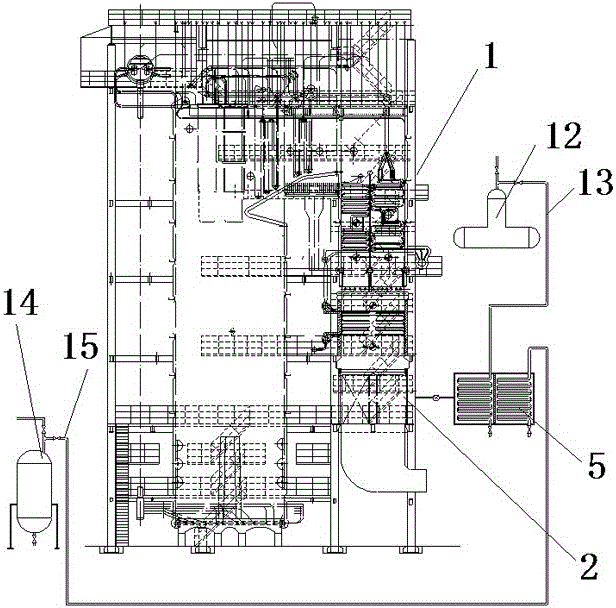

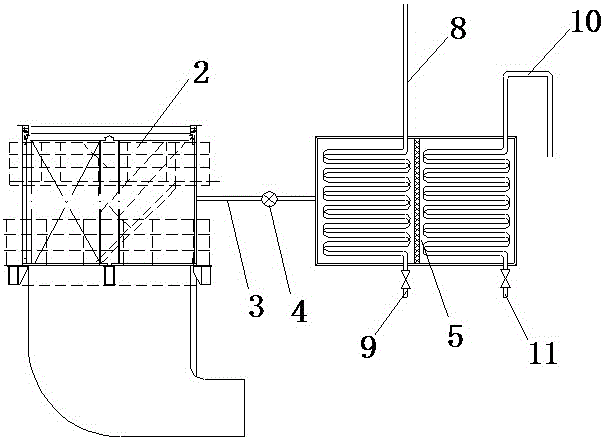

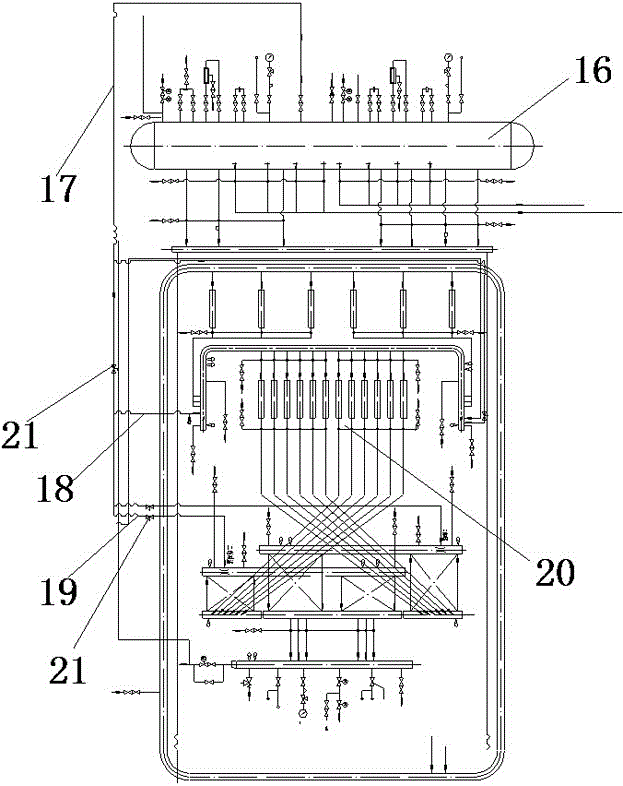

[0020] see Figure 1 to Figure 3 , the present invention relates to a boiler waste heat recovery and steam temperature control system, comprising a boiler 1, the boiler 1 is equipped with a plurality of air preheaters 2, wherein the air inlet pipe 3 of each air preheater 2 is connected with The fan 4 is connected, and the front end of the fan 4 is provided with a heat exchange device 5, and the heat exchange device 5 is provided with a cold air inlet 6, a hot air outlet 7, a first hot water inlet 8, a first cold water outlet 9, and a second hot water inlet 10. The second cold water outlet 11. There are two water pipes inside the heat exchange device 5, which are respectively connected with the first hot water inlet 8 and the first cold water outlet 9, and with the second hot water inlet 10 and the second cold water outlet 11. The first hot water inlet 8 is connected with the emptying pipe 13 on the deaerator 12 of the boiler 1, and the second hot water inlet 10 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com