Hydrogen peroxide non-enzyme sensor based on silver-graphene nano composite and manufacturing method thereof

A nanocomposite and hydrogen peroxide technology, applied in the direction of material electrochemical variables, can solve the problems of cumbersome steps and affecting the performance of catalysts, and achieve the effect of simple steps, potential application prospects, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

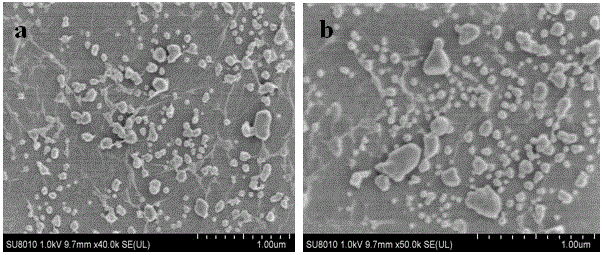

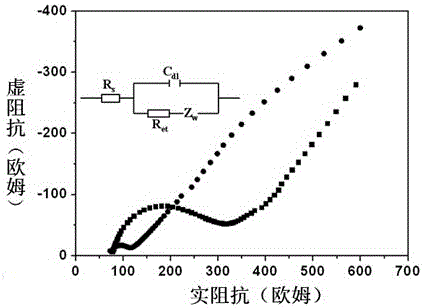

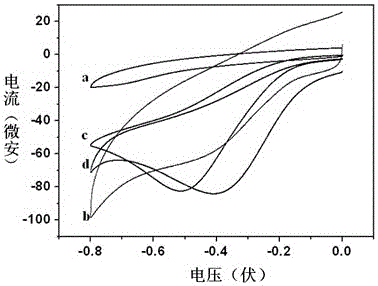

[0025] A kind of preparation method of the hydrogen peroxide enzyme-free sensor based on silver-graphene nanocomposite, it comprises the steps:

[0026] 1) Weigh 8 mg of graphene oxide and add it to 10 mL of water, ultrasonically dissolve it for 3 h to obtain a graphene oxide dispersion, centrifuge (12 min, 2500 rpm) to remove undissolved graphene oxide, and obtain brown-yellow graphite oxide Alkene solution;

[0027] 2) Configure the electrodeposition solution: to contain AgNO 3 and KNO 3 The mixed solution is used as the electrodeposition solution, wherein, the silver salt AgNO in the electrodeposition solution 3 The concentration is 5 mmol / L, supporting electrolyte KNO 3 The concentration is 0.1 mol / L;

[0028] 3) Use a pipette gun to pipette 10 μL of the graphene oxide solution obtained in step 1) and drop-coat it on the surface of the pretreated glassy carbon electrode, and let it dry at room temperature to obtain a graphene oxide-modified glassy carbon electrode; gla...

Embodiment 2

[0042] A kind of preparation method of the hydrogen peroxide enzyme-free sensor based on silver-graphene nanocomposite, it comprises the steps:

[0043] 1) Weigh 5 mg of graphene oxide and add it to 10 mL of water, ultrasonically dissolve it for 2 h to obtain a graphene oxide dispersion, centrifuge (10 min, 2000 rpm) to remove undissolved graphene oxide, and obtain brown-yellow graphite oxide Alkene solution;

[0044] 2) Configure the electrodeposition solution: to contain AgNO 3 and KNO 3 The mixed solution is used as the electrodeposition solution, wherein, the silver salt AgNO in the electrodeposition solution 3 The concentration is 1 mmol / L, the supporting electrolyte KNO 3 The concentration is 0.05 mol / L;

[0045] 3) Use a pipette gun to pipette 15 μL of the graphene oxide solution obtained in step 1) and drop-coat it on the surface of the pretreated glassy carbon electrode, and let it dry at room temperature to obtain a graphene oxide-modified glassy carbon electrode...

Embodiment 3

[0048] A kind of preparation method of the hydrogen peroxide enzyme-free sensor based on silver-graphene nanocomposite, it comprises the steps:

[0049] 1) Weigh 10 mg of graphene oxide and add it to 5 mL of water, ultrasonically dissolve it for 3 h to obtain a graphene oxide dispersion, centrifuge (15 min, 3000 rpm) to remove undissolved graphene oxide, and obtain brown-yellow graphite oxide Alkene solution;

[0050] 2) Configure the electrodeposition solution: to contain AgNO 3 and KNO 3 The mixed solution is used as the electrodeposition solution, wherein, the silver salt AgNO in the electrodeposition solution 3 The concentration is 10 mmol / L, the supporting electrolyte KNO 3 The concentration is 0.5 mol / L;

[0051] 3) Use a pipette gun to pipette 10 μL of the graphene oxide solution obtained in step 1) and drop-coat it on the surface of the pretreated glassy carbon electrode, and let it dry at room temperature to obtain a graphene oxide-modified glassy carbon electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com