Vacuum electron beam welding method for refractory alloy

A vacuum electron beam and refractory alloy technology, which is applied in vacuum electron beam welding of Nb521 niobium alloy and vacuum electron beam welding of refractory alloy, can solve the problems that niobium alloy is easily contaminated by impurities, and achieve stable welding performance, high density, Good effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

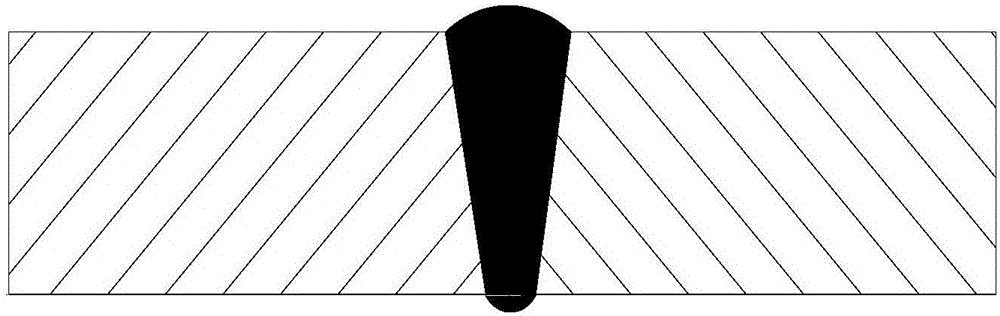

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, contents and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the examples.

[0013] The refractory alloy of the present invention adopts Nb521 niobium alloy as an embodiment, and the specification of the Nb521 niobium alloy test piece is 200mm * 60mm * 12mm, and a kind of refractory alloy vacuum electron beam welding method of the present invention comprises the following steps:

[0014] The first step: Welding surface treatment: use mechanical processing methods to process all the welding surfaces of the samples to be welded to ensure that the maximum allowable surface roughness Ra is 3.2μm, and the butt joint surface is smooth, smooth, and free of burrs, and maintain edges and corners;

[0015] Step 2: Preparation before welding: pickle the test piece to be welded, rinse it with clean water after pickling, and then dry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com