Method for preparing battery-grade lithium salt through recovering lithium bromide waste liquor

A lithium bromide, battery-grade technology is applied in the field of recovering lithium bromide waste liquid to prepare battery-grade lithium salt, which can solve problems such as waste of lithium elements, and achieve the effects of low cost, simple process and considerable economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

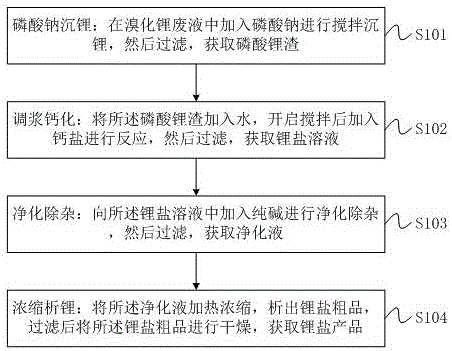

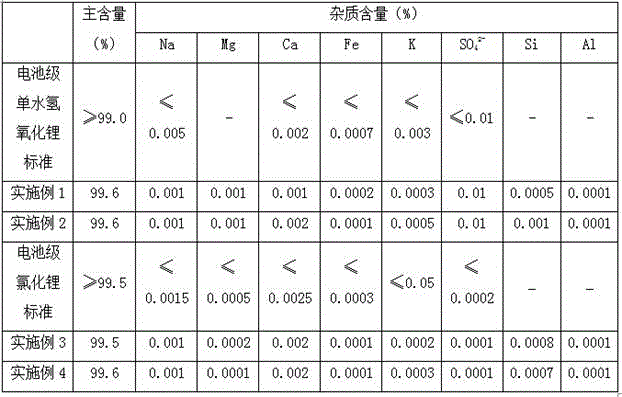

[0031] The invention provides a method for preparing battery-grade lithium salt by reclaiming lithium bromide waste liquid. The method is carried out according to the following steps:

[0032] S101: Sodium phosphate lithium precipitation: add 5% sodium phosphate, 362.9g, which is 5% more than the amount of lithium bromide to 1000g of lithium bromide waste liquid with a concentration of 55%, stir for lithium precipitation, and filter after lithium precipitation for 3 hours to obtain lithium phosphate residue ;

[0033] S102: Slurry calcification: Add the lithium phosphate slag to water, control the liquid-solid ratio of water and lithium phosphate slag to 3:1 and start stirring, then add 233.9g of calcium hydroxide, react for 2 hours and filter to obtain Lithium solution;

[0034] S103: Purification and removal of impurities: in the lithium hydroxide solution according to the volume of lithium hydroxide solution 2kg / m 3 Adding soda ash to purify and remove impurities, filter ...

Embodiment 2

[0037] The invention provides a method for preparing battery-grade lithium salt by reclaiming lithium bromide waste liquid. The method is carried out according to the following steps:

[0038] S101: Sodium phosphate lithium precipitation: Add 8% sodium phosphate, i.e. 373.3g, which is 8% more than lithium bromide to 1000g of lithium bromide waste liquid with a concentration of 55%, stir for lithium precipitation, and filter after lithium precipitation for 2 hours to obtain lithium phosphate residue ;

[0039] S102: Slurry calcification: Add the lithium phosphate slag to water, control the liquid-solid ratio of water and lithium phosphate slag to 5:1 and start stirring, then add 245.6g of calcium hydroxide, react for 3 hours and filter to obtain Lithium solution;

[0040] S103: Purification and removal of impurities: in the lithium hydroxide solution according to the volume of lithium hydroxide solution 2kg / m 3 Adding soda ash to purify and remove impurities, filter after rea...

Embodiment 3

[0043] The invention provides a method for preparing battery-grade lithium salt by reclaiming lithium bromide waste liquid. The method is carried out according to the following steps:

[0044] S101: Sodium phosphate lithium precipitation: Add 8% sodium phosphate, 352.9g, which is 8% more than lithium bromide to 1000g of lithium bromide waste liquid with a concentration of 52%, stir for lithium precipitation, and filter after lithium precipitation for 3 hours to obtain lithium phosphate solid ;

[0045] S102: Slurry calcification: add the lithium phosphate slag into water, and control the liquid-solid ratio of water and lithium phosphate solid to 5:1, then add 331.7g of calcium chloride, react for 2 hours and filter to obtain lithium chloride solution ;

[0046] S103: Purify and remove impurities: add 2kg / m of the volume of the lithium chloride solution to the lithium chloride solution 3 Soda ash was added for purification and impurity removal, and after reacting for 2 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com