An application of Cu Ce co-doping in improvement of photocatalysis performance of ZnO micropowder

A micron powder, photocatalytic technology, applied in physical/chemical process catalysts, nanotechnology for materials and surface science, metal/metal oxide/metal hydroxide catalysts, etc., to achieve increased photocatalytic performance and easy reaction Ongoing, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

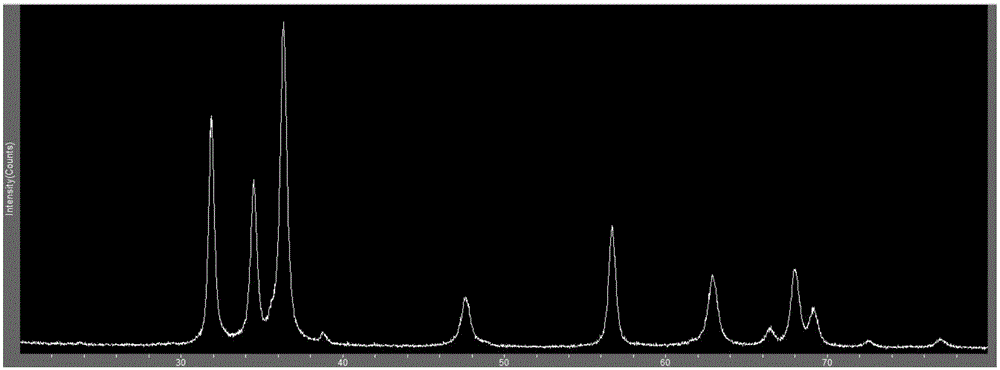

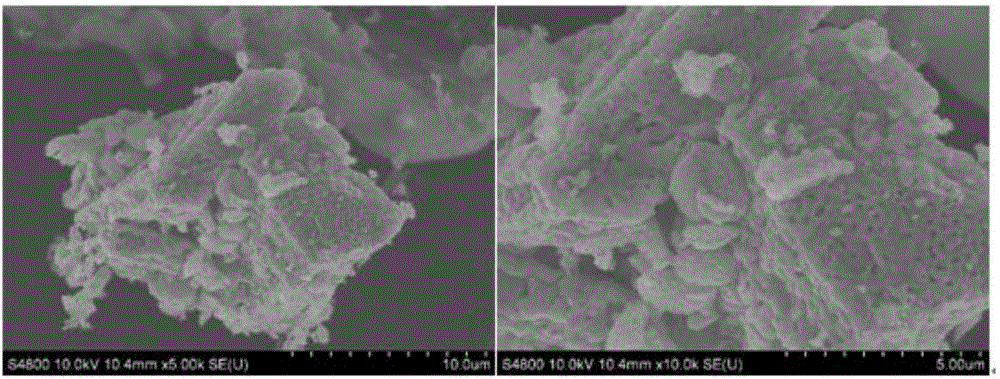

Image

Examples

Embodiment 1

[0027] The preparation method of the zinc oxide nanomaterial of the present embodiment comprises:

[0028] Step 1: prepare Zn(NO 3 ) 2 ·6H 2 O, Cu(NO with a molar concentration of 0.1mol / L 3 ) 2 ·3H 2 O, Ce(NO at a concentration of 0.1mol / L 3 ) 3 12H 2 O, C with a molar concentration of 0.3mol / L 6 h 8 o 7 ·H 2 O solution, the three solutions were magnetically stirred for 30 minutes;

[0029] Step 2: Quantitative copper solution, then zinc solution is mixed in proportion with 97% and cerium nitrate solution 0 (Zn 0.97 Cu 0.03 (0), the mixed solution was mixed with the prepared citric acid solution, and magnetically stirred for 3 hours to form a sol, and the concentration of citric acid in the sol was 0.3mol / L.

[0030] Step 3: Put the sol in an oven at 80° C. for 13 hours to keep it warm to form a xerogel. Put the dry gel into a 130°C drying oven for 9 hours to keep it warm for dehydration and puffing to obtain the precursor;

[0031] Step 4: Fully grind the pre...

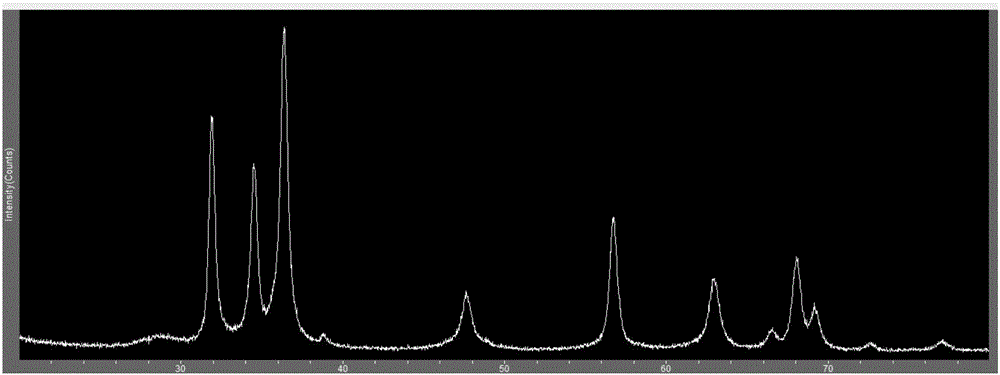

Embodiment 2

[0033] The present embodiment is different from embodiment one in that: quantitative copper solution, then zinc solution is mixed in proportion with 95% and cerium nitrate solution 2% (Zn 0.95 Cu 0.03 Ce 0.02 O).

Embodiment 3

[0035] The present embodiment is different from embodiment one in that: quantitative copper solution, then zinc solution is mixed in proportion with 93% and cerium nitrate solution 4% (Zn 0.93 Cu 0.03 Ce 0.04 O).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com