Preparation method of in-situ hydrophobic modified basic magnesium sulfate whisker

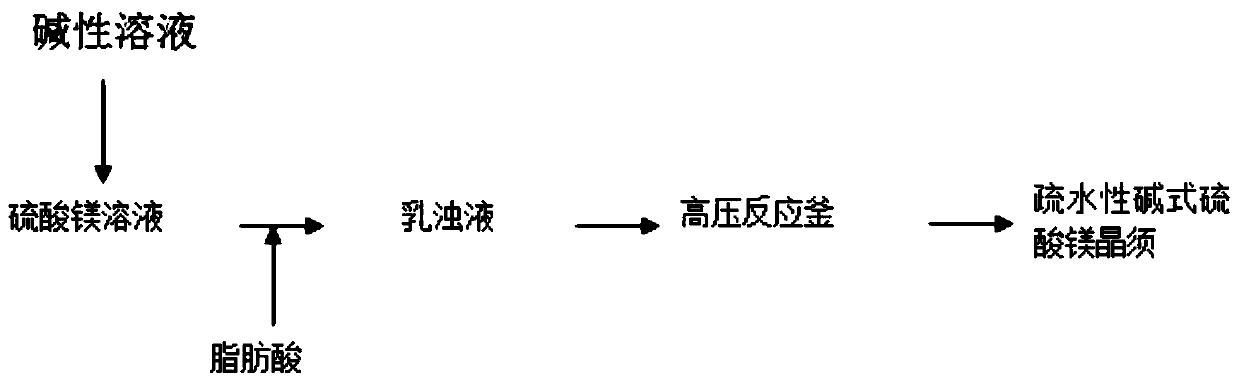

A magnesium sulfate whisker, hydrophobic modification technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problem of poor compatibility between whiskers and polymer matrix, poor compatibility and dispersion Uniformity, unsatisfactory enhancement effect, etc., to achieve good hydrophobic effect, complete crystallization, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of preparation method of in-situ hydrophobically modified basic magnesium sulfate whisker, this method drips ammoniacal liquor in magnesium sulfate solution, then adds liquid fatty acid oleic acid (being called for short OA) as in-situ modifying agent, add-on 0.5vol.% of the volume of the magnesium sulfate solution to obtain an emulsion, add the emulsion into a high-pressure reactor, carry out hydrophobic modification on the basic magnesium sulfate whiskers, and prepare the in-situ hydrophobic modification by hydrothermal synthesis For basic magnesium sulfate whiskers, the temperature of hydrothermal synthesis is 180°C, the time is 5 hours, and the rotation speed is 500r / min.

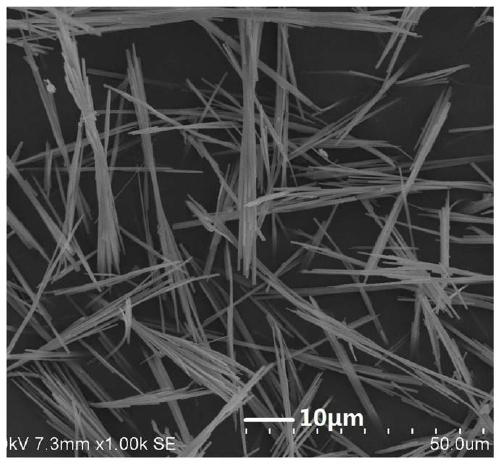

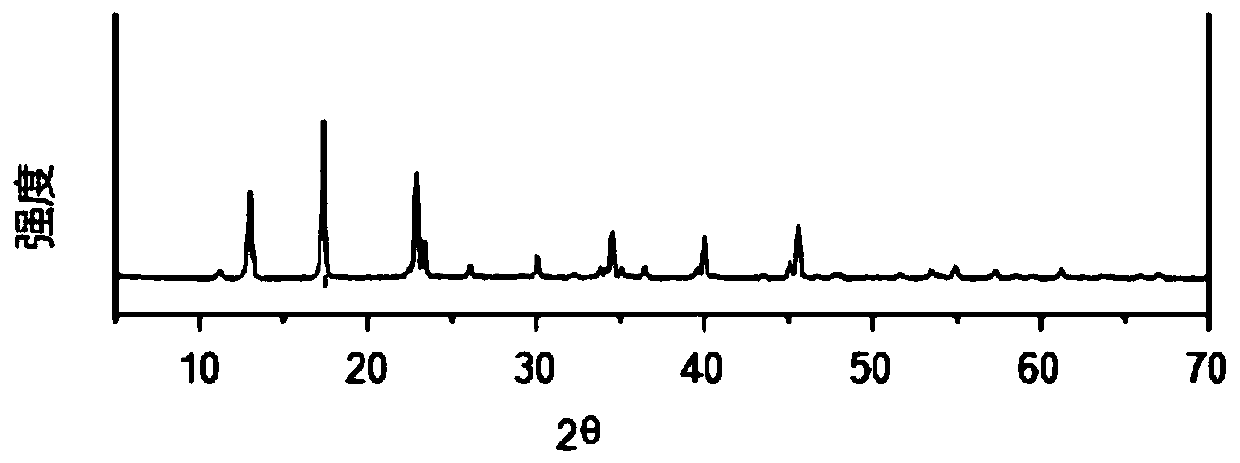

[0036] Carry out SEM scanning analysis and XRD pattern analysis to the prepared in-situ hydrophobically modified basic magnesium sulfate whisker, obtain as follows figure 2 The SEM images shown and image 3 As shown in the XRD figure, it can be known that the in-situ hydroph...

Embodiment 2

[0038] A kind of preparation method of in-situ hydrophobic modification basic magnesium sulfate whisker, this method drips sodium hydroxide in magnesium sulfate solution, then adds solid fatty acid stearic acid / ethanol (being called for short EtOH) as in-situ modifying agent, Add-on is 1.5vol.% of the magnesium sulfate solution volume, and the volume ratio of solid fatty acid stearic acid and ethanol in the in-situ modifying agent is 1:1, obtains emulsion, and emulsion is added in autoclave, to Basic magnesium sulfate whiskers were hydrophobically modified, and in-situ hydrophobically modified basic magnesium sulfate whiskers were prepared by hydrothermal synthesis. The temperature of hydrothermal synthesis was 200°C, the time was 7 hours, and the rotation speed was 200r / min.

[0039] Carry out SEM scanning analysis and XRD pattern analysis to the prepared in-situ hydrophobically modified basic magnesium sulfate whisker, obtain as follows Figure 4 The SEM images shown and F...

Embodiment 3

[0041] A kind of preparation method of in-situ hydrophobic modification basic magnesium sulfate whisker, this method drips potassium hydroxide in magnesium sulfate solution, then adds palmitic acid / ethylene glycol (being called for short EG) as in-situ modifying agent, adds The amount is 2.5vol.% of the volume of magnesium sulfate solution, and the volume ratio of palmitic acid and ethylene glycol in the in-situ modifier is 1:2 to obtain an emulsion, and the emulsion is added to the autoclave, and the alkali formula The magnesium sulfate whiskers were hydrophobically modified, and the in-situ hydrophobically modified basic magnesium sulfate whiskers were prepared by hydrothermal synthesis. The temperature of the hydrothermal synthesis was 140°C, the time was 1h, and the rotation speed was 700r / min.

[0042] Carry out SEM scanning analysis and XRD pattern analysis to the prepared in-situ hydrophobically modified basic magnesium sulfate whisker, obtain as follows Figure 6 The S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com