Method for increasing yield and polymerization degree of polymeric phosphorus-nitrogen intumescent flame retardant

A technology of intumescent flame retardant and degree of polymerization, which is applied in the field of preparation of polymeric flame retardants, can solve the problems of complex purification process of synthetic products, structural characterization of synthetic products, failure to achieve the use effect, etc., and achieve simplified post-processing procedures, excellent Mechanical properties, beneficial to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

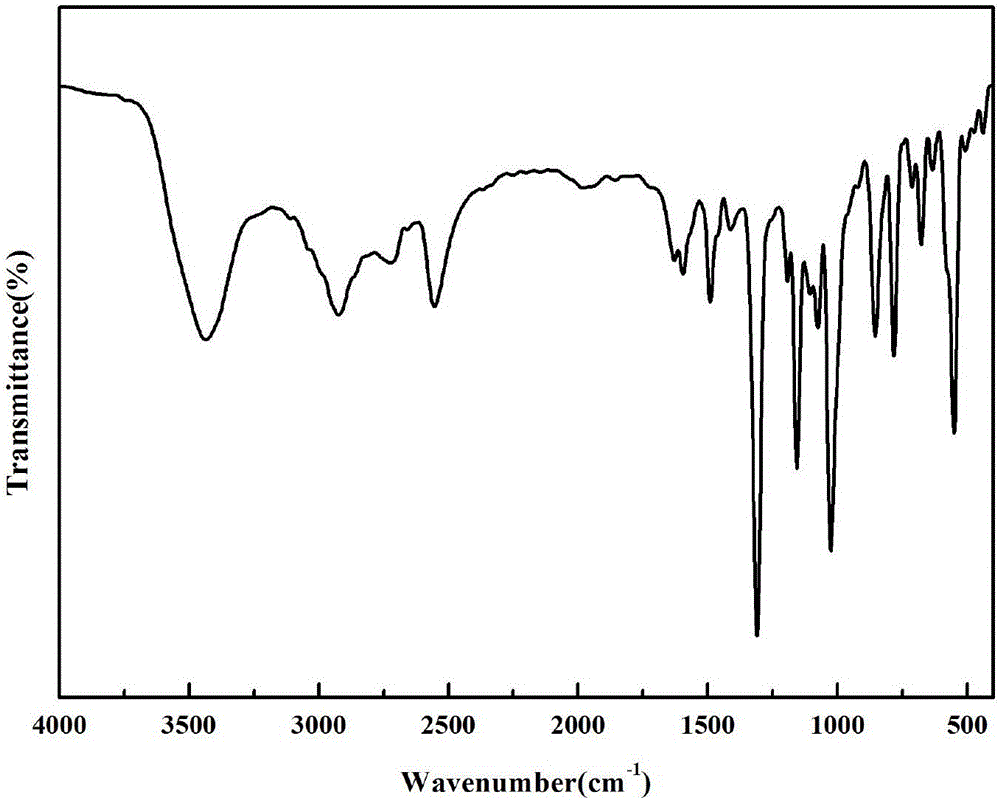

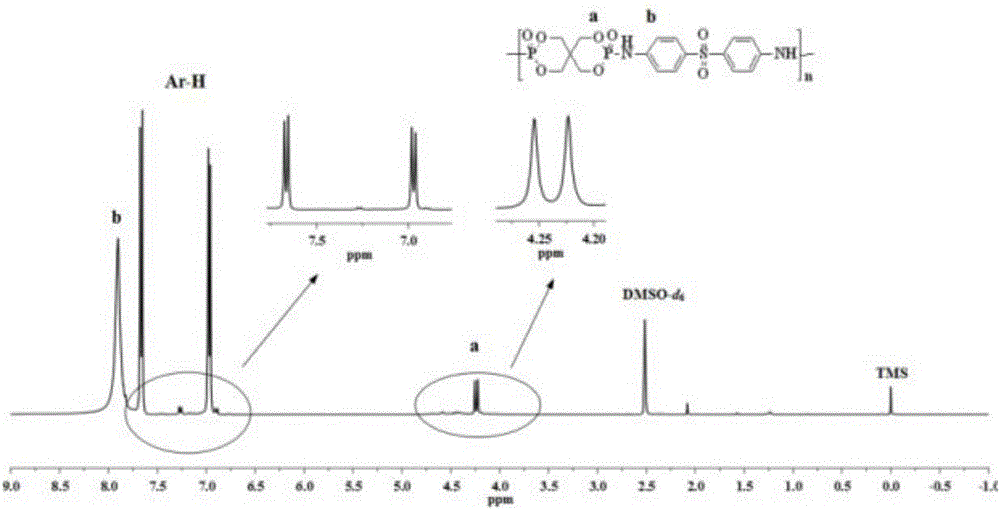

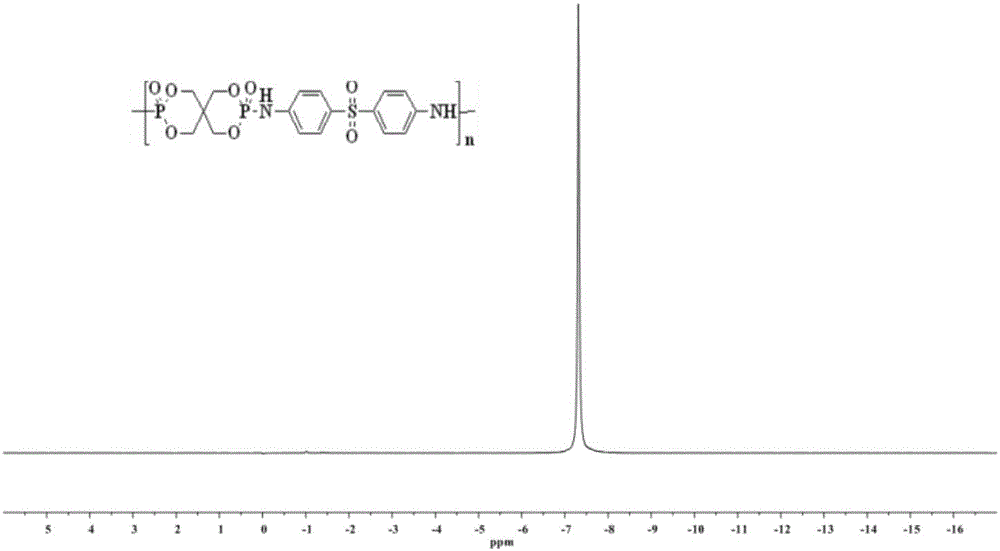

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Under the protection of nitrogen, add 6.8g (0.05mol) of just ground pentaerythritol (PER), 23.1g (0.15mol) of just distilled phosphorus oxychloride (POCl) to a 500ml container 3 ) and 0.72g aluminum trichloride (AlCl 3 ). Connect the above-mentioned reaction vessel with a thermometer, a mechanical stirrer, a reflux condenser and a tail gas absorption device. Mix at room temperature first, and the rotation speed of the stirring blade is 230r / min. After the system is uniformly mixed, slowly raise the temperature to 80°C until the reaction is complete, that is, no hydrogen chloride gas appears. After the reaction, the excess phosphorus oxychloride solvent was recovered by distillation with a rotary evaporator, and the obtained residue was washed with dichloromethane, filtered, and recrystallized in glacial acetic acid after repeated several times. Dry at 120°C to constant weight to obtain 13.5 g of white intermediate pentaerythritol diphosphate diphosphoryl chlor...

Embodiment 2

[0047] Step 1: Under the protection of nitrogen, add 6.8g (0.05mol) of freshly ground PER, 30.6g (0.20mol) of freshly distilled POCl into a 500ml container 3 and 0.74g AlCl 3 , connect the above-mentioned reaction vessel with a thermometer, a mechanical stirrer, a reflux condenser and an exhaust gas absorption device. Mix at room temperature first, and the rotation speed of the stirring blade is 230r / min. After the system is uniformly mixed, slowly raise the temperature to 75°C until the reaction is complete, that is, no hydrogen chloride gas appears. After the reaction, the excess POCl was recovered by distillation with a rotary evaporator 3 Solvent, the obtained residue was washed with dichloromethane, filtered, and after repeated several times, recrystallized in glacial acetic acid, and the recrystallized product was dried in a blast oven at 120°C to constant weight to obtain a white intermediate SPDPC 13.7 g, the yield is 92.3%, and the purity is 98.6%;

[0048] Step 2:...

Embodiment 3

[0050] Step 1: Under the protection of nitrogen, add 6.8g (0.05mol) of freshly ground PER, 30.6g (0.20mol) of freshly distilled POCl into a 500ml container 3 and 0.74g AlCl 3 . Connect the above-mentioned reaction vessel with a thermometer, a mechanical stirrer, a reflux condenser and a tail gas absorption device. Mix at room temperature first, and the rotation speed of the stirring blade is 230r / min. After the system is uniformly mixed, slowly raise the temperature to 60°C until the reaction is complete, that is, no hydrogen chloride gas appears. After the reaction, the excess POCl was recovered by distillation with a rotary evaporator 3 Solvent, the obtained residue was washed with dichloromethane, filtered, and after repeated several times, recrystallized in glacial acetic acid, and the recrystallized product was dried in a blast oven at 120°C to constant weight to obtain a white intermediate SPDPC 13.6 g, the yield is 91.6%, and the purity is 98.3%;

[0051] Step 2: Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com