Method for removing aflatoxin B1 (AFB1) by use of fusarium and enzyme produced by fusarium

A technology of aflatoxin and Fusarium, applied in the field of microorganisms, can solve the problems of rare and difficult biodegradable compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method for the bacterial agent that is used to remove the aflatoxin B1 in the biomass material that the third aspect of the present invention relates to, it comprises:

[0045] Step B, inoculating the fermentation strain into the fermentation medium for fermentation culture to obtain a fermentation culture;

[0046] In step C, the fermentation culture is concentrated and separated, and then cleaned and separated to obtain Fusarium wet bacteria (that is, the bacterial agent used to remove aflatoxin B1 in the biomass material);

[0047] Wherein, the fermented strains are obtained from corresponding bacterial strains through seed cultivation.

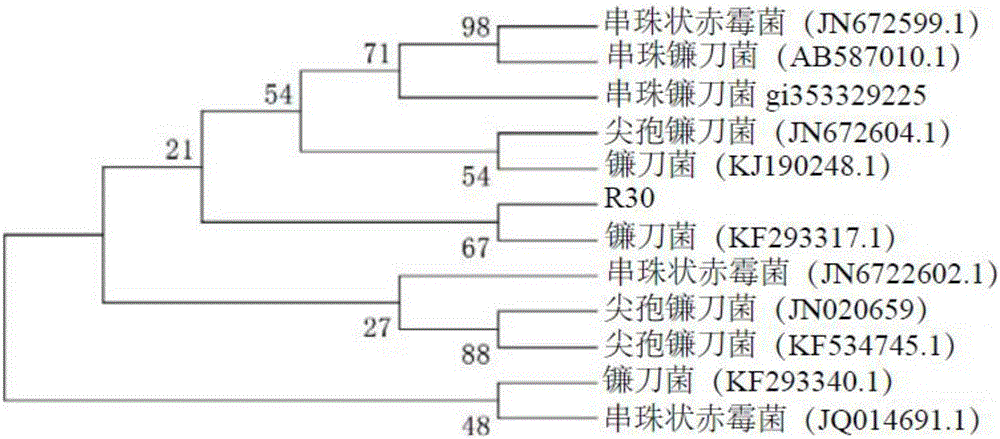

[0048] As known to those skilled in the art, at present, 18S Ribosomal RNA (18S rRNA) is often used internationally for molecular identification of bacteria, so 18S rRNA can be used for comparison of similarities to obtain their homology. Therefore, the fermentation strains used in the present invention are not limi...

Embodiment 1

[0100] Embodiment 1: preparation is used to remove the bacterial agent of aflatoxin B1 in the biomass material

[0101] (1) Prepare the fermentation medium, put 100ml of the prepared liquid fermentation medium into a 500ml triangular flask, seal the bottle mouth with a parafilm, sterilize it at high temperature (121°C) and high pressure (0.15MPa) for 20min, and then place it on a clean bench Use after 20 minutes of internal ultraviolet irradiation sterilization.

[0102] Described fermenting medium comprises the following components in 1L of water in 1L of water:

[0103]

[0104]

[0105] In some embodiments of the present invention, a solution of 40% (weight) sodium hydroxide and 36% (v / v) hydrochloric acid is used to adjust the initial pH value of the fermentation medium to 7.2.

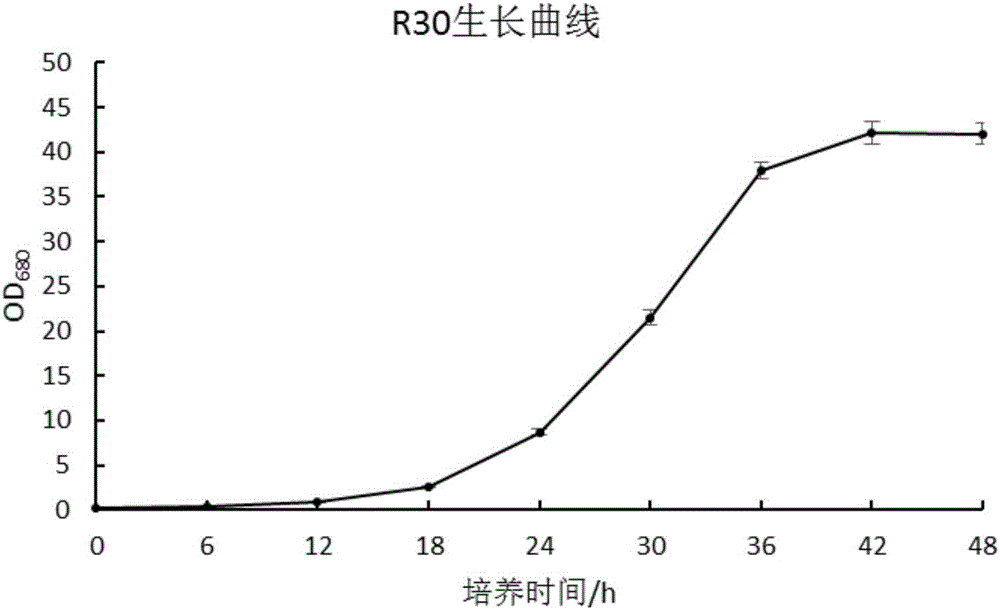

[0106] (2) Seed cultivation, picking the monoclonal colonies of Fusarium solani R30 strain provided by the present invention and inoculating them into 10ml of fermentation broth, cultivatin...

Embodiment 2

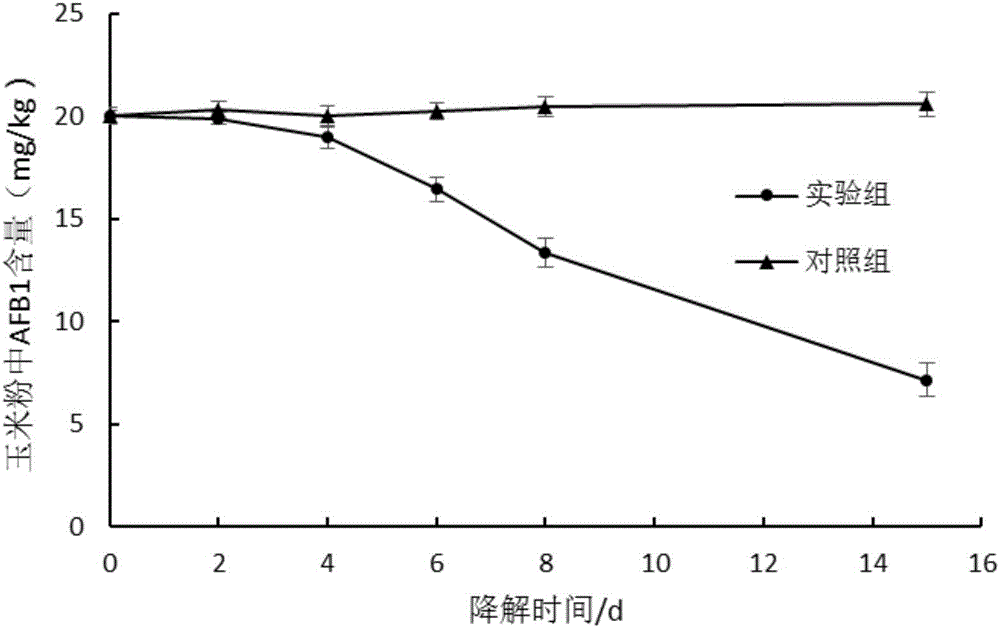

[0112] Embodiment 2: Adopt Fusarium solani R30 to remove aflatoxin B1 in corn

[0113] Take by weighing 50g initial AFB1 content and be 20mg / kg, the cornflour that water content is 16.7%, the wet thalline that makes in the embodiment 1 of 0.1g is added in the cornflour, put into airtight plastic belt after fully mixing, Cultured statically at a temperature of 30°C.

[0114] On the 0th, 2nd, 4th, 6th, 8th, and 15th day, 4 grams of samples were taken respectively, of which 2g of corn flour was placed in a 50mL Erlenmeyer flask, 10mL of ethanol was added to vibrate and extracted for 1h, filtered through a 0.22u inorganic filter membrane, and nitrogen was placed at 60°C Blow dry to 2ml for HPLC determination of AFB1 concentration. The water content of another 2g sample was measured by the 130°C timed drying method, which was used for the conversion of AFB1 concentration in the final corn.

[0115] Kinetic process of Fusarium solani R30 biodegradation of AFB1 in maize image 3 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com