Etching solution for etching multilayer thin film comprising copper layer and titanium layer etching method using said solution and substrate obtained by using said method

A technology for etching liquid and substrate, applied in the field of etching liquid, can solve the problems of low copper resistance, reduced hydrogen peroxide stability, slow dissolution of titanium, etc., and achieve the effects of high processing accuracy, less unevenness, and long bath life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

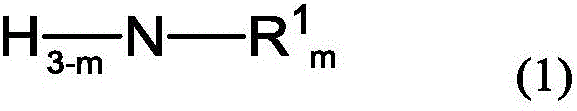

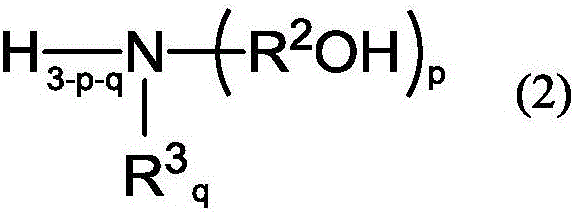

[0157] Added 5.88% by mass of hydrogen peroxide, 4.12% by mass of nitric acid, 0.25% by mass of acid ammonium fluoride, 0.21% by mass of 5-amino-1H-tetrazole, 0.03% by mass of phenylurea and water, with pH value becomes 1.5~2.5, add 2-aminoethanol (Example 1), 2-dimethylaminoethanol (Example 2), 3-methoxypropylamine (Example 3), N-Butylamine (Example 4), N-Methyl-n-Butylamine (Example 5), Isopropanolamine (Example 6), 3-amino-1-propanol (Example 7), N-Butylamine Ethanolamine (Example 8), N,N-Dimethylamino-2-propanol (Example 9) and 2-methoxyethylamine (Example 10).

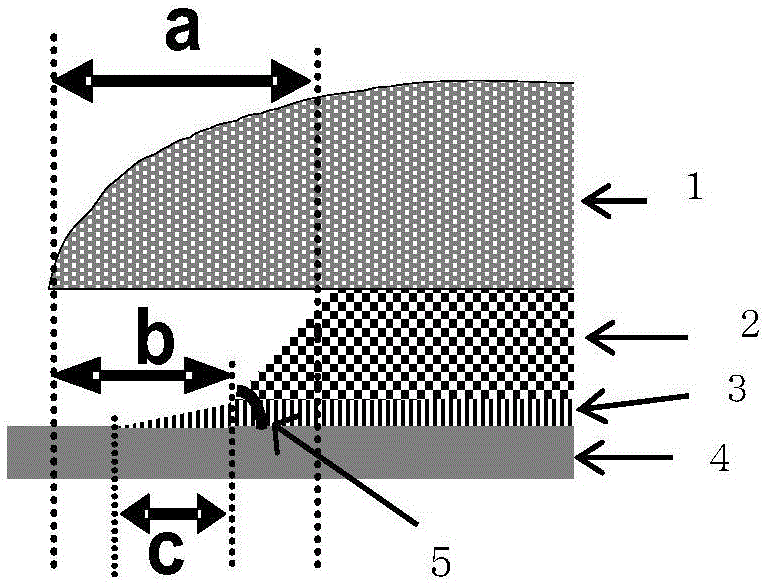

[0158] The above-obtained glass substrate having a multilayer thin film comprising a copper layer and a titanium layer was immersed in the above etching solution at 35° C. for 150 seconds for etching to obtain an etched multilayer thin film sample comprising a copper layer and a titanium layer. For the obtained sample, the cone angle (°), top CD loss (a, μm), bottom CD loss (b, μm) and tailing (c, μm) were obtain...

Embodiment 4

[0161] In Example 4, the concentration of hydrogen peroxide was set to 3.0% by mass (Comparative Example 1) and 9.0% by mass (Comparative Example 2), and the concentration of nitric acid was set to 0.70% by mass (Comparative Example 3) and 9.00% by mass (Comparative Example 3). 4), 5-amino-1H-tetrazole was set to 0.08% by mass (Comparative Example 5) and 0.60% by mass (Comparative Example 6), and the concentration of the amine compound (n-butylamine) was set to 0.20% by mass (Comparative Example 7) and 11.0% by mass (Comparative Example 8) and 0.08% by mass (Comparative Example 9) and 0.80% by mass (Comparative Example 10) of acidic ammonium fluoride resulted in problems such as inability to measure the etched shape or loss of wiring. The results are summarized in Table 3 and Table 4.

Embodiment 1

[0171] Example 1: 2-Aminoethanol (manufactured by Wako Pure Chemical Industries, Ltd.)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com