Method for recycling well flushing waste water in in-situ leaching uranium exploration

A technology of wastewater circulation and in-situ leaching for uranium production, which is applied in wellbore flushing, earthwork drilling, wellbore/well components, etc. It can solve the problem that the method cannot meet the needs of production, the amount of well-washing wastewater is large, and uranium cannot be effectively recovered. Recycling and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

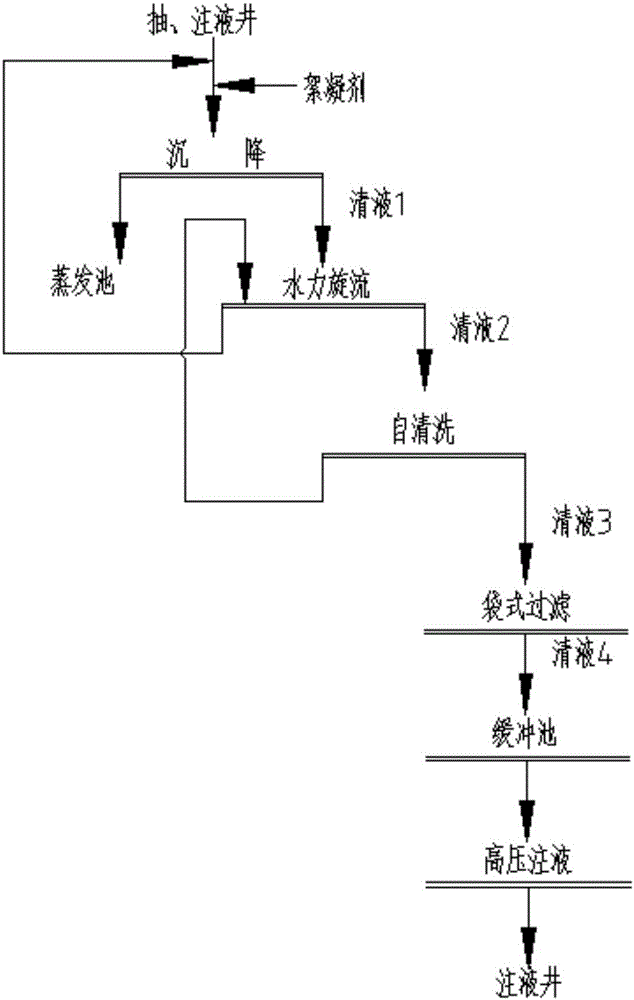

[0021] Such as figure 1 Shown, a kind of method for recycling waste water from uranium mining by in-situ leaching of the present invention, it comprises the following steps:

[0022] (a) Lifting the well-washing wastewater of the pumping and injection wells for uranium mining by in-situ leaching to the surface, and then settling through the settling tank, the bottom flow slurry of the settling tank is discharged into the evaporation pool, and the supernatant 1 of the settling tank enters step (b);

[0023] After being clarified by the settling tank, the silt (sand) content of the clear liquid 1 is less than 5.3%, and the particle size distribution is greater than 50 μm, accounting for 90%.

[0024] (b) The supernatant liquid 1 is sent into the hydrocyclone, and the clear liquid 2 coming out of the hydrocyclone enters step (c); the sand-containing solution coming out of the hydrocyclone is returned to the settling tank, and a closed-circuit circulation process is carried out; ...

Embodiment 2

[0032] Such as figure 1 Shown, a kind of method for recycling waste water from uranium mining by in-situ leaching of the present invention, it comprises the following steps:

[0033] (a) Lifting the well-washing wastewater of the pumping and injection wells for uranium mining by in-situ leaching to the surface, and then settling through the settling tank, the bottom flow slurry of the settling tank is discharged into the evaporation pool, and the supernatant 1 of the settling tank enters step (b);

[0034] After being clarified in the settling tank, the mud (sand) content of the clear liquid 1 is less than 4.2%, and the particle size distribution is greater than 50 μm, accounting for 75%.

[0035] (b) The supernatant liquid 1 is sent into the hydrocyclone, and the clear liquid 2 coming out of the hydrocyclone enters step (c); the sand-containing solution coming out of the hydrocyclone is returned to the settling tank, and a closed-circuit circulation process is carried out;

...

Embodiment 3

[0043] Such as figure 1 Shown, a kind of method for recycling waste water from uranium mining by in-situ leaching of the present invention, it comprises the following steps:

[0044] (a) Lifting the well-washing wastewater of the pumping and injection wells for uranium mining by in-situ leaching to the surface, and then settling through the settling tank, the bottom flow slurry of the settling tank is discharged into the evaporation pool, and the supernatant 1 of the settling tank enters step (b);

[0045] After being clarified by the settling tank, the mud (sand) content of the clear liquid 1 is less than 4.8%, and the particle size distribution is greater than 50 μm, accounting for 85%.

[0046] (b) The supernatant liquid 1 is sent into the hydrocyclone, and the clear liquid 2 coming out of the hydrocyclone enters step (c); the sand-containing solution coming out of the hydrocyclone is returned to the settling tank, and a closed-circuit circulation process is carried out;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com