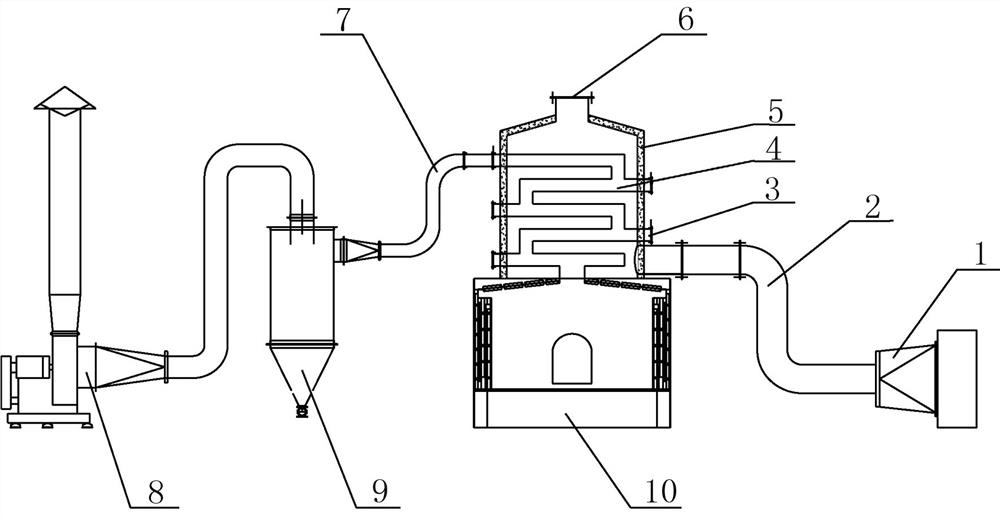

Fertilizer production process hot air supply system using waste heat of flue gas

A production process and hot air supply technology, applied in the field of hot air supply system for fertilizer production process, can solve the problems of increased operating costs and high energy consumption, and achieve the effects of reducing gel fluidity, saving energy and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Add polyacrylamide and distilled water into the container at a mass ratio of 8:92, heat to 94°C, stir until completely dissolved, cool to gel, and obtain product A;

[0032] 2) Mix product A, potassium chloride, sodium dodecylbenzenesulfonate and iron powder according to the mass ratio of 10:6:5:80 and then granulate to obtain gel particles, which are called product B; and,

[0033] Product A, zinc powder, potassium chloride and sodium dodecylbenzenesulfonate are mixed according to a mass ratio of 10:80:6:6 and then granulated to obtain gel particles, which are called product C;

[0034] 3) When using, product B and product C are compatible according to the mass ratio of 1:1 to obtain the self-heating material of the present invention.

Embodiment 2

[0036] 1) Add sodium alginate and distilled water into the container according to the mass ratio of 3:97, heat to 80°C, stir until completely dissolved, cool to gel, and obtain product A;

[0037] 2) Mix product A, potassium sulfate, sodium lauryl sulfate and iron powder according to the mass ratio of 5:1:10:93 and then granulate to obtain gel particles, which are called product B; and,

[0038] Product A, magnesium powder, potassium sulfate and sodium lauryl sulfate are mixed according to a mass ratio of 15:65:10:1 and then granulated to obtain gel particles, which are called product C;

[0039] 3) When in use, product B and product C are combined according to the mass ratio of 15:85 to obtain the self-heating material of the present invention.

Embodiment 3

[0041] 1) Add gelatin and distilled water into the container according to the mass ratio of 15:60, heat to 98°C, stir until completely dissolved, cool to gel, and obtain product A;

[0042] 2) Mix product A, sodium sulfate, sorbitan fatty acid ester-20 and iron powder according to the mass ratio of 15:10:1:65 and then granulate to obtain gel particles, which are called product B; and,

[0043] Product A, lead powder, sodium sulfate and sorbitan fatty acid ester-20 are mixed according to a mass ratio of 5:93:1:10 and then granulated to obtain gel particles, which are called product C;

[0044] 3) When in use, product B and product C are combined according to the mass ratio of 85:15 to obtain the self-heating material of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com