Control circuit of traction type automatic encapsulation equipment

A control circuit and traction technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as low efficiency, difficult cost control, poor quality, etc., and achieve the effect of improving the quality and efficiency of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

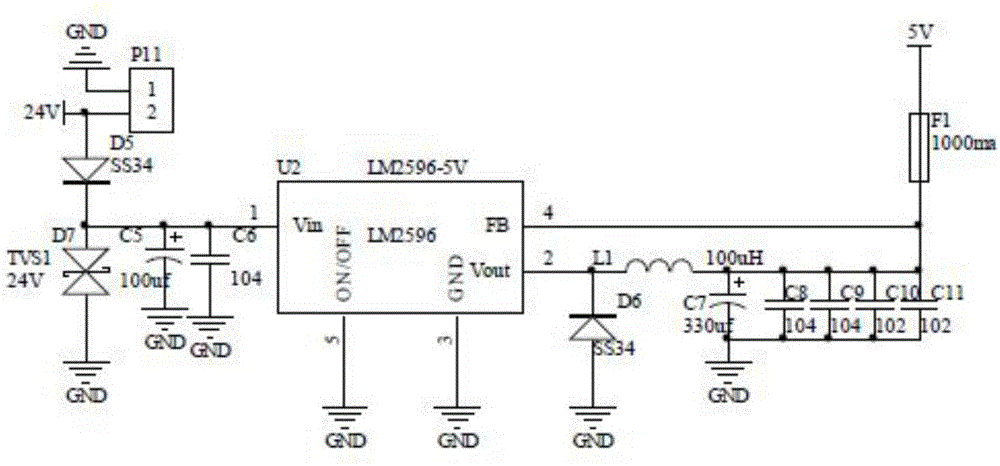

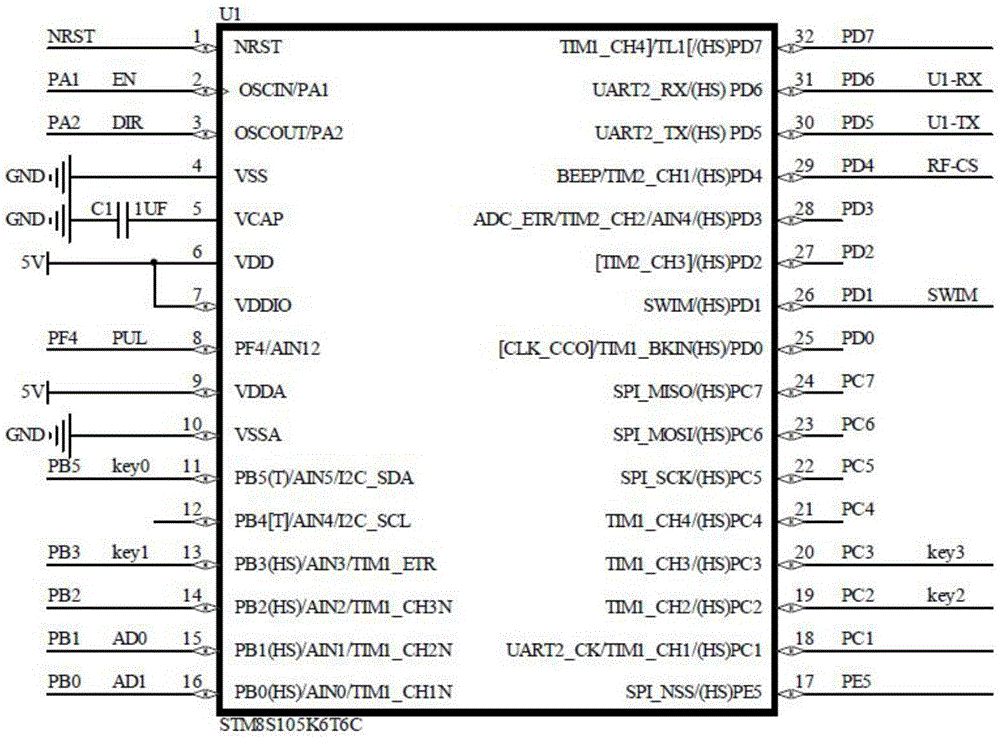

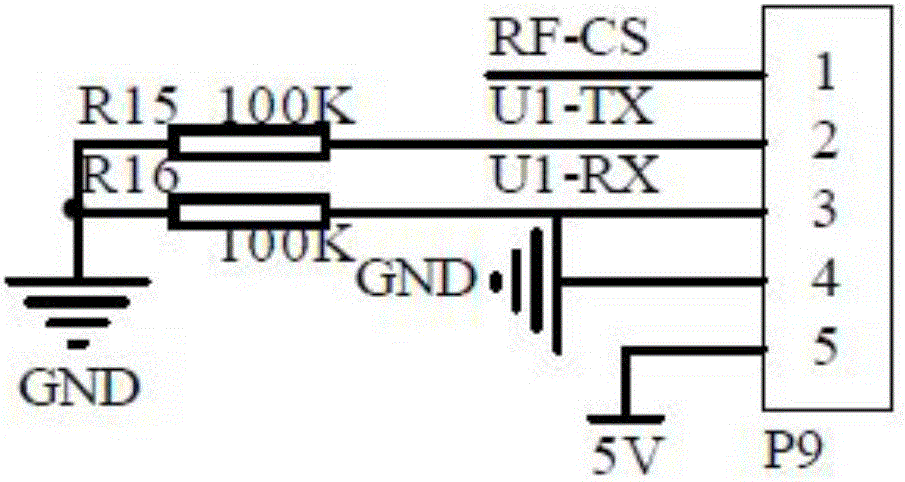

[0048] Such as Figure 1-15 As shown, a control circuit of traction automatic rubber encapsulation equipment, including switching power supply circuit, minimum system circuit of single chip microcomputer, communication interface circuit of encapsulation machine, two potentiometer interface circuits, roller electromagnet control interface circuit, stepper motor driver Interface circuit, roller trigger button circuit, roller pressing trigger button circuit, power indicator light interface circuit, pedal interface circuit, error clear button interface circuit, error indicator light interface circuit, buzzer circuit, download interface circuit and reset circuit ;

[0049] Such as figure 1 As shown, the switching power supply circuit includes: voltage conversion chip U2, first and second pin connector P11, anti-reverse connection diode D5, TVS tube D7, aluminum electrolytic capacitors C5 and C7, capacitor C6 and capacitors C8 ~ C11, current storage diode D6 , inductance L1, fuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com