Method and apparatus for etching semiconductor substrate

A semiconductor and substrate technology, applied in the field of etching semiconductor substrates, can solve the problems of slow gas phase etching rate, loss of practical application value, poor etching uniformity, etc., to improve etching uniformity and avoid adhesion” effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for etching a semiconductor substrate, and the method includes the following steps:

[0040] Step 101: converting the hydrofluoric acid liquid into hydrofluoric acid vapor, and converting the alcohol liquid into alcohol gas;

[0041] Step 102: Introduce the hydrofluoric acid vapor and the alcohol gas into the process chamber at the same time, the hydrofluoric acid vapor etches the substrate in the process chamber, and the alcohol gas acts as a moisturizing agent. The wet gas forms a uniform micro-condensation layer on the surface of the substrate. For example, hydrofluoric acid vapor is etching SiO 2 When the reaction product contains water, the alcohol gas in the process chamber and the surface of the substrate can be combined with water to prevent the formation of liquid water condensation phase on the surface of the substrate. The condensed water formed on the surface of the substrate will seriously affect the hydrofluoric acid. Et...

Embodiment 2

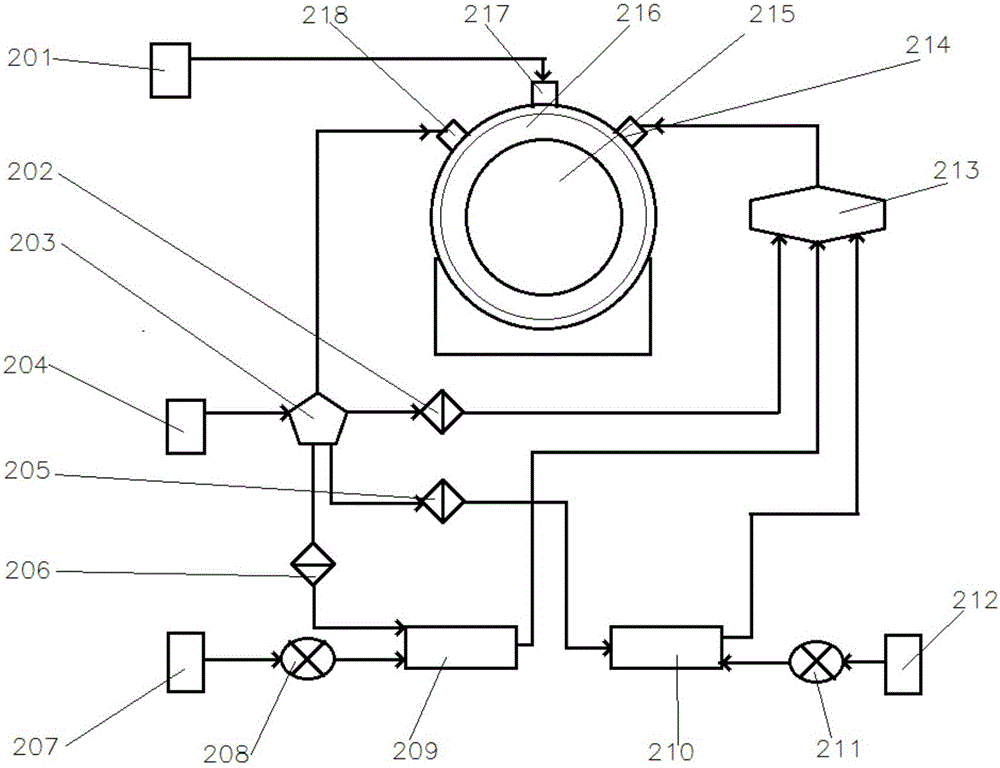

[0049] like figure 1 As shown, this embodiment provides a device for etching a semiconductor substrate, the device includes: a process chamber 216, a first pump 208, a first evaporator 209, a second pump 211, a second evaporator 210, a first A collection manifold and nozzles. Wherein, the process chamber 216 is used for placing the substrate 215, and the substrate 215 is subjected to an etching process in the process chamber 216; the first pump 208 pumps the hydrofluoric acid liquid into the first In the evaporator 209, the hydrofluoric acid liquid is partially converted into hydrofluoric acid vapor in the first evaporator 209; the second pump 211 pumps the alcohol liquid into the second evaporator 210, so The alcohol liquid is converted into alcohol gas in the second evaporator 210; the first collection manifold 203 is respectively connected to the first evaporator 209 and the second evaporator 210 through pipelines; nitrogen gas enters The first collection manifold 203 ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com