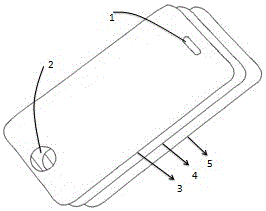

Sapphire mobile phone protecting film and processing technology thereof

A mobile phone film and processing technology, applied in the field of sapphire application, can solve the problems of easy breaking of mobile phones, high production cost, easy to produce scratches, etc., and achieve both economic and environmental benefits, stable mass production, and quality reduction. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

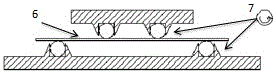

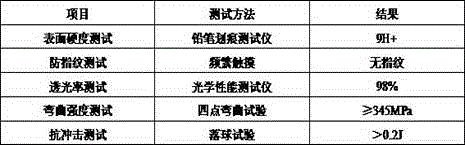

Embodiment 1

[0015] Select an ingot with colorless uniformity, high transparency, no bubbles, grain boundaries and other defects, use the crystal orientation instrument to accurately locate the A side (18°55'), cut out the rectangular square material of the A side with a diamond wire swing cutting machine, and pass through the Head and tail, surface grinding to improve the flatness of the square (≤0.2 mm). Glue the rectangular square material on the resin strip and fix it on the workbench of the cutting machine, adjust the slot distance of the multi-wire cutting machine, set the descending speed of the workbench and the wire supply program to first decelerate and then accelerate, and the wafer is soaked to remove the glue after testing After qualified, rough grinding removes the line marks on the surface and improves the flatness of the workpiece surface. Use the Jingdiao machine to process the shape of the mobile phone film and chamfer the edges. Laser cut the rough outline of the listeni...

Embodiment 2

[0017] Select a crystal ingot with colorless uniformity, high transparency, no bubbles, grain boundaries and other defects, use the crystal orientation instrument to accurately locate the A side, cut out the rectangular square material of the A side with a diamond wire swing cutting machine, and improve it by removing the head and tail and plane grinding Square material flatness (≤0.2 mm). Glue the rectangular square material on the resin strip and fix it on the workbench of the cutting machine, adjust the slot distance of the multi-wire cutting machine, set the descending speed of the workbench within the range of 10-30 mm / h, and the wire supply at 5- Within the range of 20 m / min, decelerate first and then accelerate. After the wafer is soaked to remove the glue, after passing the test, the rough grinding removes the line marks on the surface and improves the flatness of the workpiece surface. Use the Jingdiao machine to process the shape of the mobile phone film and chamfer...

Embodiment 3

[0019] Select a crystal ingot with colorless uniformity, high transparency, no bubbles, grain boundaries and other defects, use the crystal orientation instrument to accurately locate the A side, cut out the rectangular square material of the A side with a diamond wire swing cutting machine, and improve it by removing the head and tail and plane grinding Square material flatness (≤0.2 mm). Glue the rectangular square material on the resin strip and fix it on the workbench of the cutting machine, adjust the slot distance of the multi-wire cutting machine, set the descending speed of the workbench and the wire supply program to first decelerate and then accelerate, and the wafer is soaked to remove the glue after testing After qualified, rough grinding removes the line marks on the surface and improves the flatness of the workpiece surface. Use the Jingdiao machine to process the shape of the mobile phone film and chamfer the edges. Laser cut the rough outline of the listening h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com