Method for preparing ionic catalyst and carrying out catalytic conversion on carbon dioxide

A catalyst and ionic technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low density of loaded catalysts, large demand for carriers, and recycling Poor effect and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

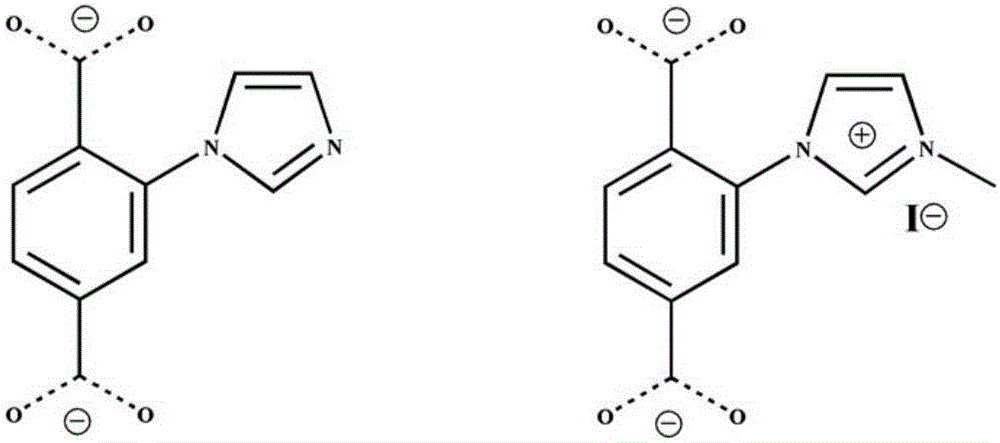

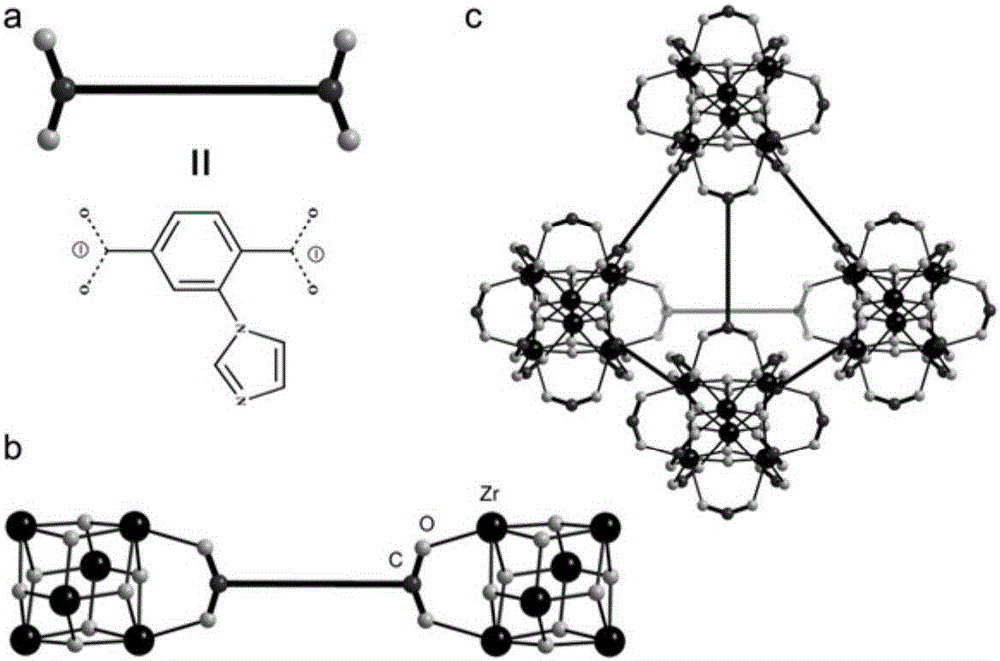

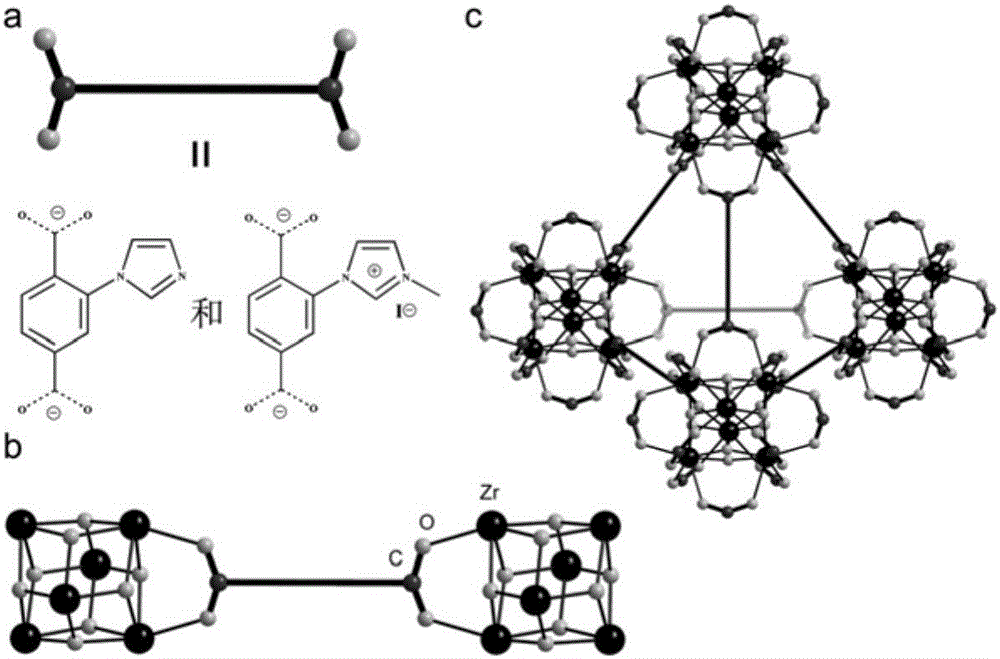

[0011] Example 1: Imidazole functionalized porous coordination polymer 1

[0012] At room temperature, add 2-imidazole terephthalic acid and zirconium tetrachloride into the mixed solution of N,N'-dimethylformamide and acetic acid according to the same amount of substances, and gradually raise the temperature to 120°C, and react After 48 hours, cool down to room temperature, centrifuge to separate the solid, wash with N,N'-dimethylformamide, wash with methanol, and dry in vacuo to obtain imidazole-functionalized porous coordination polymer 1.

Embodiment 2

[0013] Example 2: Imidazolium salt functionalized porous coordination polymer ionic catalyst 2

[0014] At room temperature, disperse the catalyst precursor and 10 times molar equivalent of methyl iodide in anhydrous acetonitrile solvent, react at 80°C for 48 hours, cool down to room temperature, centrifuge to separate the solid, wash and centrifuge with acetonitrile, methanol and ether successively, and dry in vacuo , to obtain ionic catalyst 2.

Embodiment 3

[0015] Embodiment 3: Ionic catalyst 2 catalyzes epichlorohydrin to obtain cyclic carbonate reaction

[0016] Under room temperature, add 0.052mmol ionic catalyst {[(I - )Meim-BDC] x [im-BDC] 1-x [Zr 6 o 4 (OH) 4 ]} n , 10mmol epichlorohydrin, the ratio of the amount of the two substances is 13:2500, closed system, keep CO 2 The reaction temperature was 1 atm, the reaction temperature was 100°C, and after 24 hours of reaction, the cyclic carbonate was diluted with ethyl acetate, dried over anhydrous sodium sulfate, and separated by column chromatography to obtain the corresponding chloromethylene cyclic carbonate with a conversion rate of 88%. Selectivity 94%; Catalyst 2 was washed with ethyl acetate, washed with acetone, dried in vacuum, and recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com