Outer skin material for hangar, and preparation method of outer skin material

An outer skin and hangar technology, which is applied in the field of outer skin materials of hangars and their preparation, can solve the problems of surface discoloration, reduced visible light effect, no infrared stealth of outer skin materials, etc., and achieves excellent weather resistance, realizes Infrared stealth performance and thermal insulation performance, the effect of reducing the fluctuation of differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

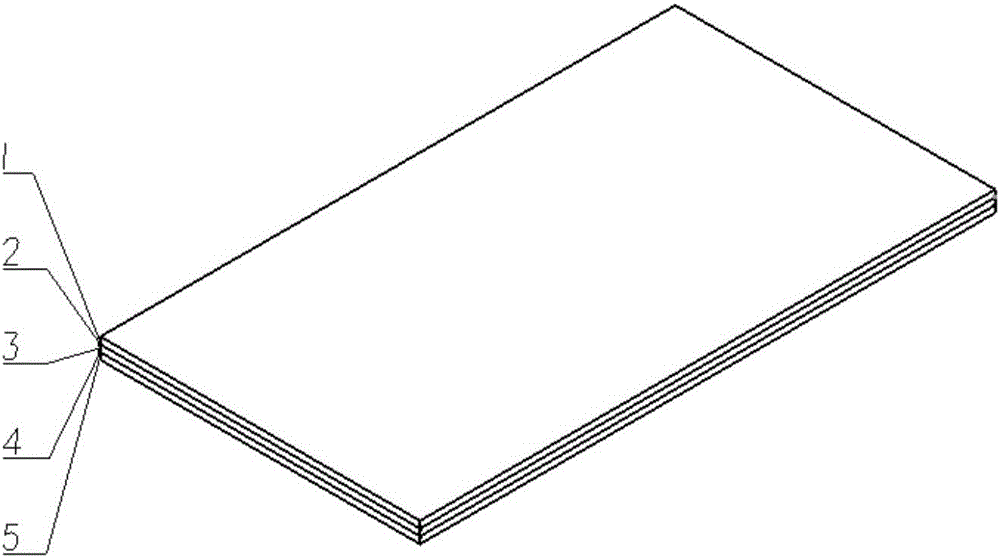

[0024] like figure 1 As shown, the outer skin material of the present invention includes a weather-resistant layer 1, a first adhesive layer 2, a reinforcement layer 3, a second adhesive layer 4 and a heat insulation layer 5, and the reinforcement layer 3 passes through the first adhesive layer 2 It is glued to the weather-resistant layer 1, and the other side of the reinforcement layer 3 is glued to the second adhesive layer 4 and the heat insulation layer 5.

[0025] The weather-resistant layer 1 is made of polyether-type TPU film with a thickness of 10-20 μm and a density of 12-24 g / m 2 .

[0026] The reinforcing layer 3 is 210D nylon fiber Oxford cloth, the weaving density is 25*25 per centimeter, and the density is 120-130g / m 2 .

[0027] Both the first adhesive layer 2 and the second adhesive layer 4 use two-component polyurethane glue with a density of 10-15g / m 2 .

[0028] The heat insulation layer 5 is a double-sided aluminized PET film with a thickness of 7 μm a...

Embodiment 2

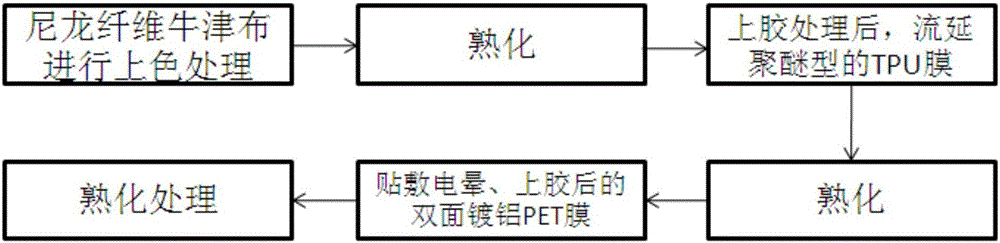

[0031] The following will be combined with figure 2 The preparation technology of the present invention is described in further detail with embodiment.

[0032] The present invention also provides a method for preparing the outer skin material, which comprises the following steps:

[0033] Step 1: Color the nylon fiber Oxford cloth according to the design, and cure it at 40°C for 24 hours.

[0034] Step 2: After gluing the nylon fiber Oxford cloth, casting a polyether-type TPU film, aging at 40° C. for 24 hours.

[0035] Step 3: Apply corona-glued double-sided aluminized PET film to the surface of the matured cast TPU nylon fiber Oxford cloth, and cure at 40°C for 24 hours.

[0036] In the heat insulation layer of this embodiment, the double-sided aluminized PET film is used to replace the single-layer aluminized PET film. After the composite heat insulation test, it is found that the emissivity is only 0.14, which is far lower than the required 0.6. The component polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com