Method for preparing germanium selenide powder

A technology of germanium selenide and powder, which is applied in the direction of chemical instruments and methods, binary selenium/tellurium compounds, metal selenide/telluride, etc., which can solve the problems of difficult control of germanium selenide, less research, and difficult preparation of solid-phase reaction, etc. problems, to achieve the effect of being convenient for mass production, simple process method, and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

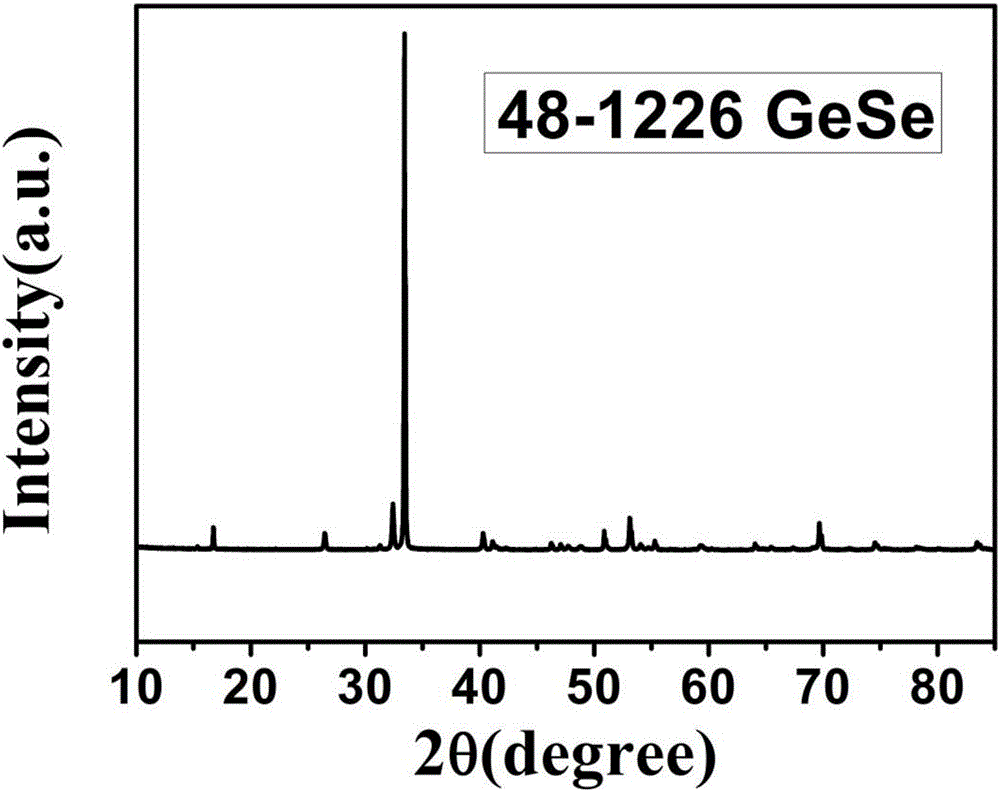

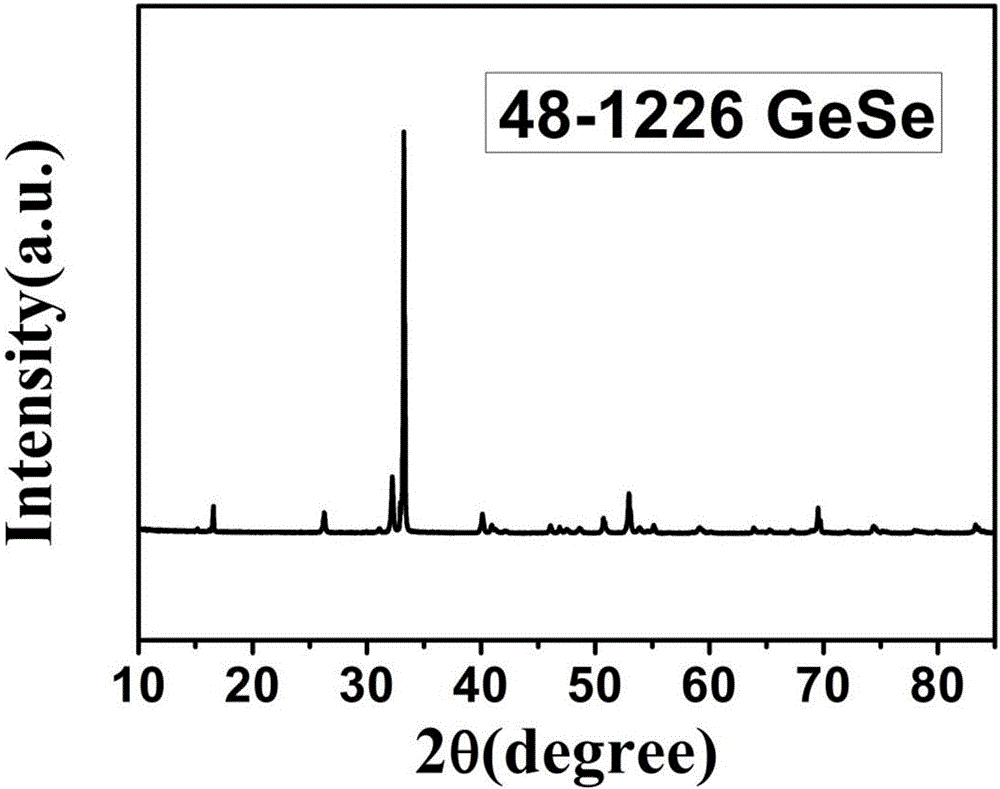

Image

Examples

Embodiment 1

[0025] A preparation method of germanium selenide powder is prepared by mixing germanium powder and selenium powder evenly, first heating and heat-preserving under vacuum condition, and then pulverizing under the protection of argon gas.

[0026] The method specifically includes the following steps:

[0027] (1) Mix germanium powder and selenium powder with a molar ratio of 1:1 with an agate mortar, then put them into a quartz crucible or corundum crucible, and finally put the quartz crucible or corundum crucible into a vacuum furnace; germanium powder The particle diameters of the germanium powder and the selenium powder are all less than or equal to 500 nanometers; after mixing the germanium powder and the selenium powder evenly according to the proportion, first briquetting;

[0028] (2) Vacuumize the vacuum furnace, replace the gas with argon for more than 10 times, and finally raise the temperature of the Zhenke furnace to 660°C at a rate of 3°C / min under vacuum, keep it ...

Embodiment 2

[0032] A preparation method of germanium selenide powder is prepared by mixing germanium powder and selenium powder evenly, first heating and heat-preserving under vacuum condition, and then pulverizing under the protection of argon gas.

[0033] The method specifically includes the following steps:

[0034] (1) Mix germanium powder and selenium powder with a molar ratio of 1:1.2 with an agate mortar, then put them into a quartz crucible or corundum crucible, and finally put the quartz crucible or corundum crucible into a vacuum furnace; germanium powder The particle diameters of the germanium powder and the selenium powder are all less than or equal to 500 nanometers; after mixing the germanium powder and the selenium powder evenly according to the proportion, first briquetting;

[0035] (2) Vacuumize the vacuum furnace, and replace the gas with argon for more than 10 times, and finally raise the temperature of the Zhenke furnace to 680°C at a rate of 5°C / min under vacuum, ke...

Embodiment 3

[0039] A preparation method of germanium selenide powder is prepared by mixing germanium powder and selenium powder evenly, first heating and heat-preserving under vacuum condition, and then pulverizing under the protection of argon gas.

[0040] The method specifically includes the following steps:

[0041] (1) Mix germanium powder and selenium powder with a molar ratio of 1:1.1 with an agate mortar, then put them into a quartz crucible or corundum crucible, and finally put the quartz crucible or corundum crucible into a vacuum furnace; germanium powder The particle diameters of the germanium powder and the selenium powder are all less than or equal to 500 nanometers; after mixing the germanium powder and the selenium powder evenly according to the proportion, first briquetting;

[0042] (2) Vacuumize the vacuum furnace, replace the gas with argon for more than 10 times, and finally raise the temperature of the Zhenke furnace to 670°C at a rate of 10°C / min under vacuum, keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com