Calcium carbide smelting furnace

A smelting furnace and calcium carbide technology, applied in the field of calcium carbide production equipment, can solve the problems of large system energy consumption, no energy coupling, and ineffective utilization of high-temperature exhaust heat energy, so as to reduce system energy consumption, reduce energy consumption costs, and improve energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments, so as to better understand the solutions of the present invention and the advantages of various aspects thereof. However, the specific embodiments and examples described below are for illustrative purposes only, and are not intended to limit the present invention.

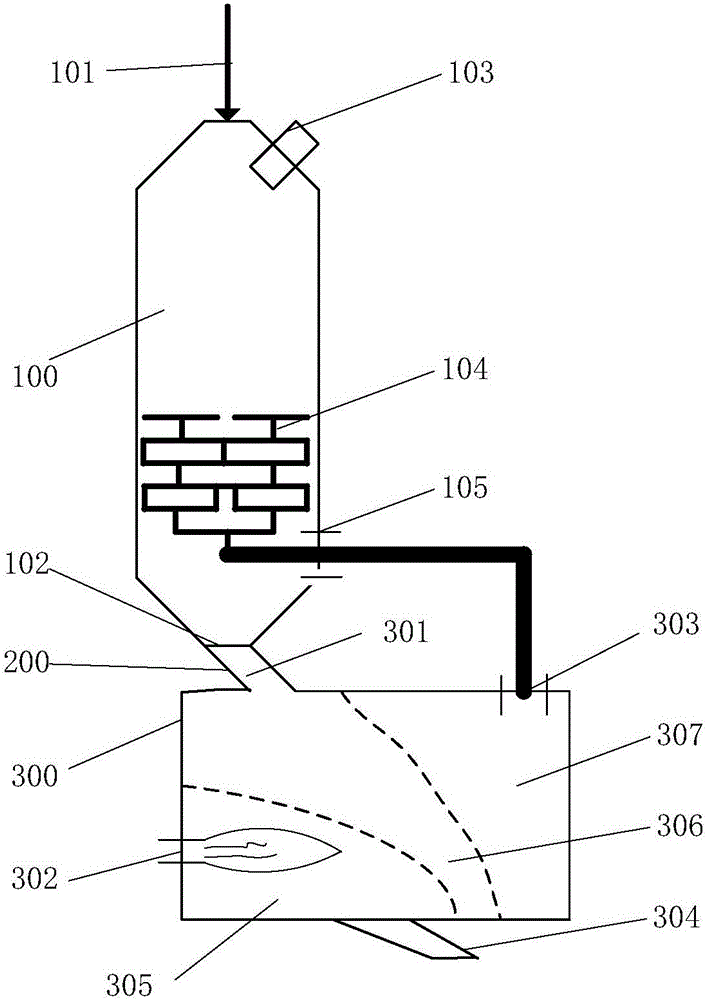

[0028] like figure 1 As shown, the embodiment of the present invention provides a calcium carbide smelting furnace, which includes a heat treatment section 100 , a hot material conveying pipe 200 and an oxygen-thermal reduction section 300 .

[0029] The heat treatment section 100 includes a raw material inlet 101 , a hot material outlet 102 , an oil and gas collection port 103 , and a gas distributor 104 .

[0030] The upper part and the lower part of the heat treatment section 100 are conical, and the middle is cylindrical, so that the material enters and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com