Low-temperature exhaust heat concentration system and method utilizing wastewater of thermal power plant

A concentration system, low-temperature waste heat technology, applied in the direction of gaseous effluent wastewater treatment, etc., can solve the problems of high flue gas temperature, flue evaporation stroke, shutdown or demolition, waste water damage, etc., to achieve a small footprint and easy operation Reliable, low energy consumption for operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

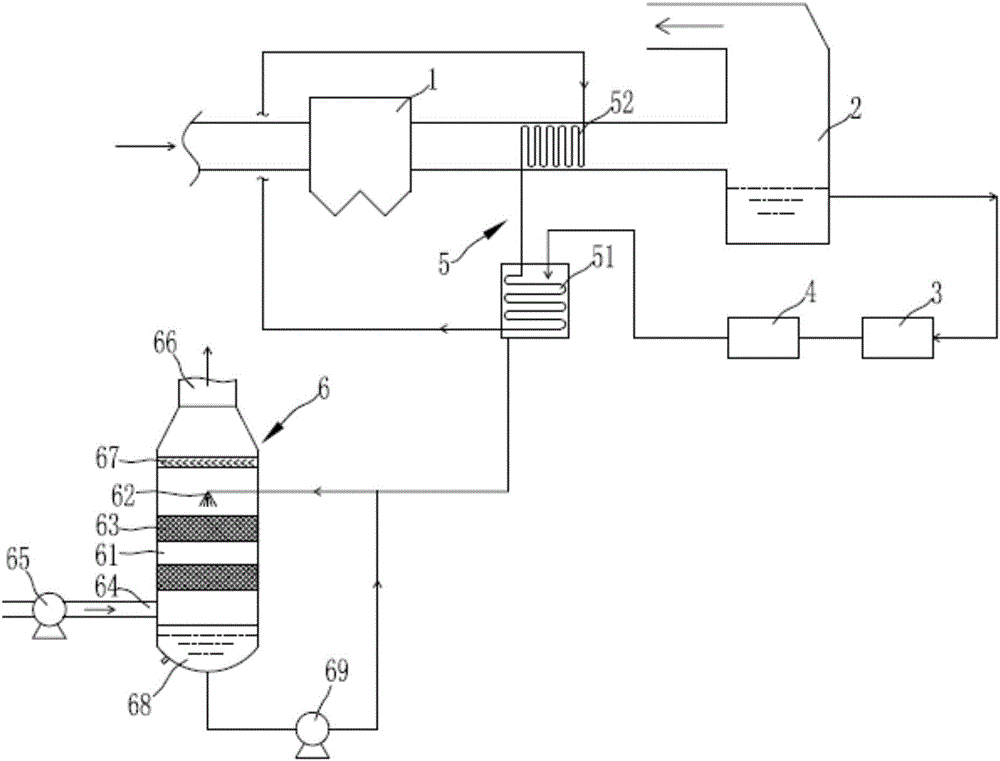

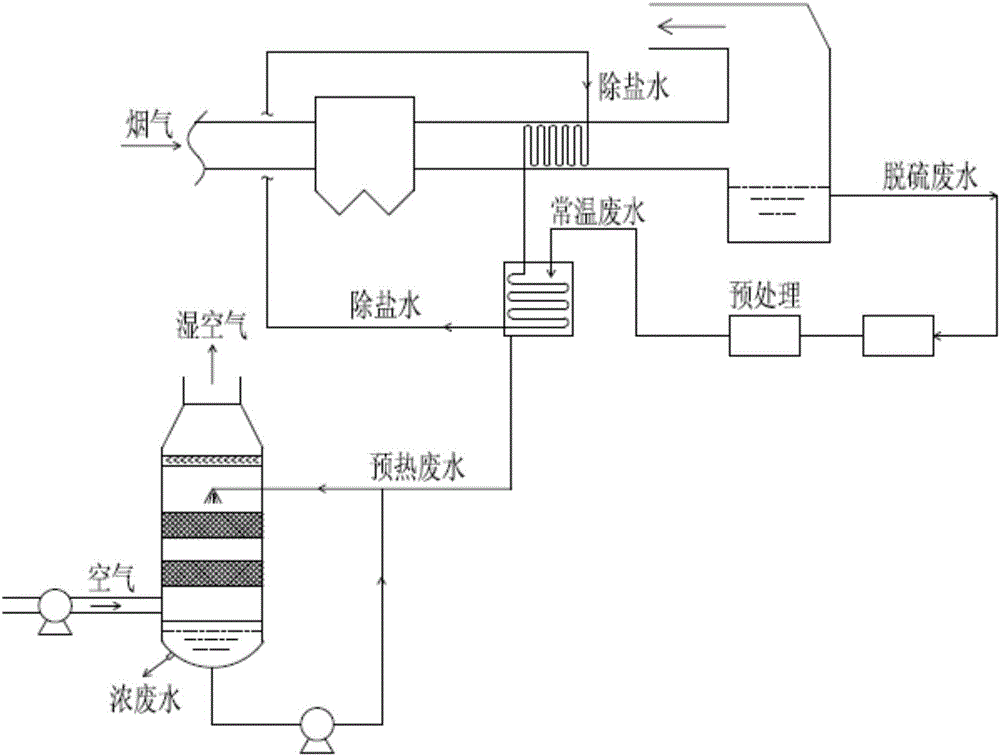

[0040] Such as figure 1 and figure 2 As shown, the low-temperature waste heat concentration system for thermal power plant waste water includes a dust collector 1 (electrical dust collector can be used) for dedusting the flue gas discharged from the boiler, a desulfurization absorption tower 2 for desulfurizing the dust-removed flue gas, and a storage desulfurization absorption tower. The waste water collecting tank 3 of the waste water produced by the tower 2 and the pretreatment device 4 for pretreatment of the waste water in the waste water collecting tank 3; The equipment implements its corresponding functions, so I won’t go into details here; it also includes:

[0041] Wastewater preheating device 5, which utilizes the flue gas heat in the flue between the dust remover 1 and the desulfurization absorption tower 2 to preheat the pretreated waste water; in this embodiment, the waste water preheating device 5 includes the The wastewater preheater 51 downstream of the pret...

Embodiment 2

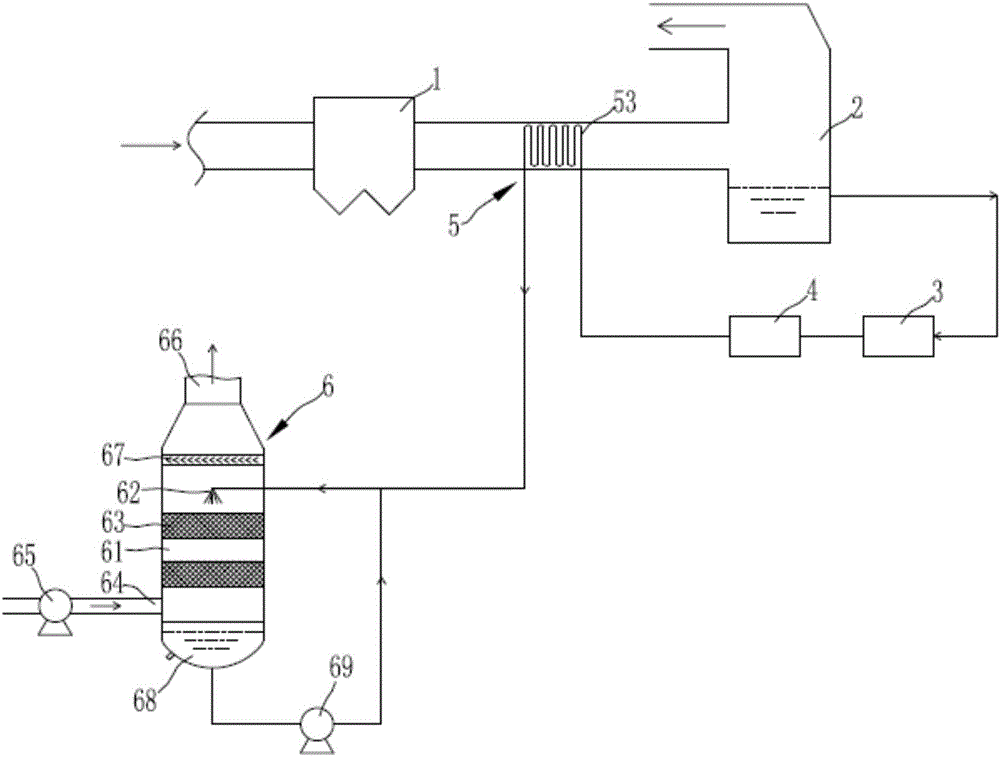

[0049] Such as image 3 and Figure 4 As shown, the low-temperature waste heat concentration system for thermal power plant waste water in this embodiment is basically the same in structure and principle as in Embodiment 1, and the similarities will not be repeated here. The only difference is:

[0050] In this embodiment, the wastewater preheating device 5 adopts a direct preheating method, that is, the wastewater after pretreatment such as neutralization, precipitation, flocculation, and clarification directly flows through and is arranged between the dust collector 1 and the desulfurization absorption tower 2 The coil 53 in the flue is preheated, and then enters the evaporative concentration tower for evaporative concentration, but this method needs to strictly control the preheating temperature (40-50°C) of the waste water. If the preheating temperature is too high, the Ca( HCO 3 ) 2 and Mg(HCO 3 ) 2 The thermal decomposition in the coil produces serious Ca and Mg ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com