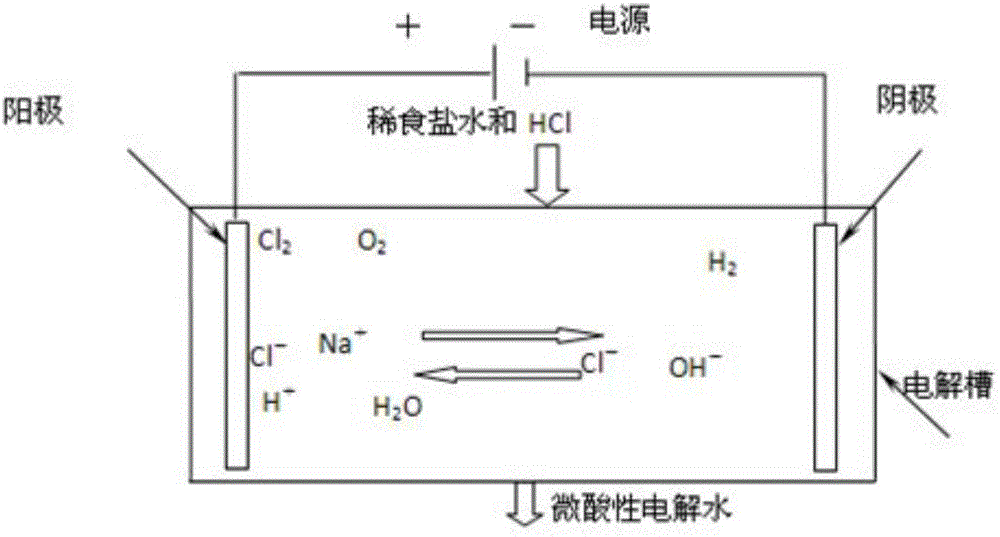

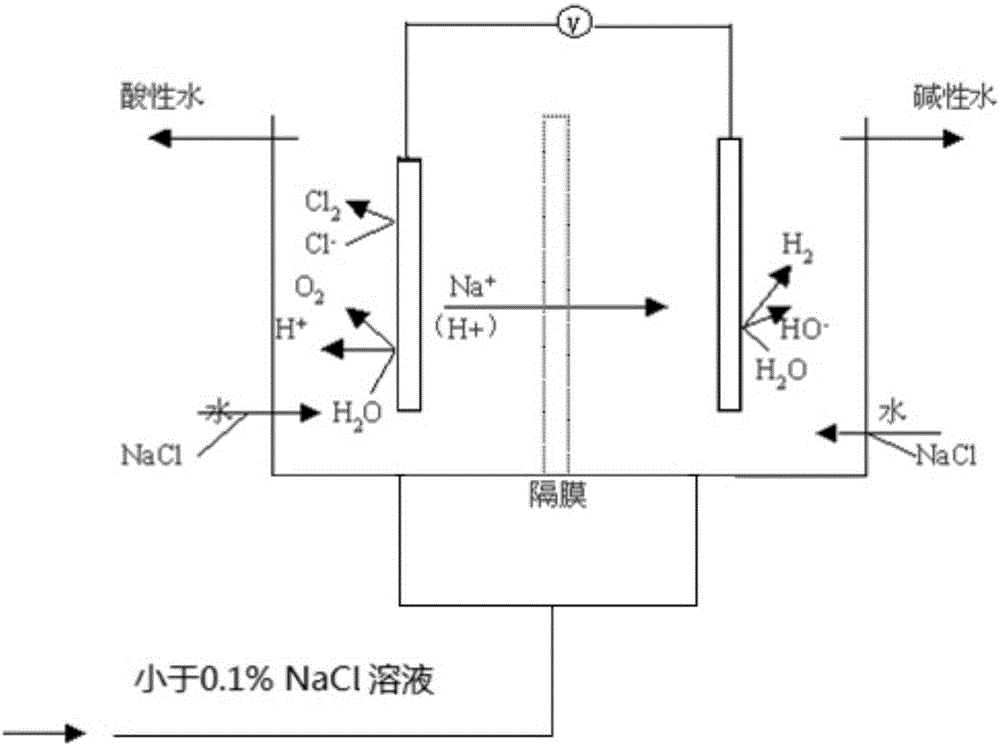

Method and device for producing subacid electrolyzed water

A technology of slightly acidic electrolyzed water and electrolytic cell, which is applied in the field of water treatment, can solve the problem that slightly acidic electrolyzed water has not been reported, and achieves the effects of being suitable for mass production, convenient for procurement, convenient for transportation, storage and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

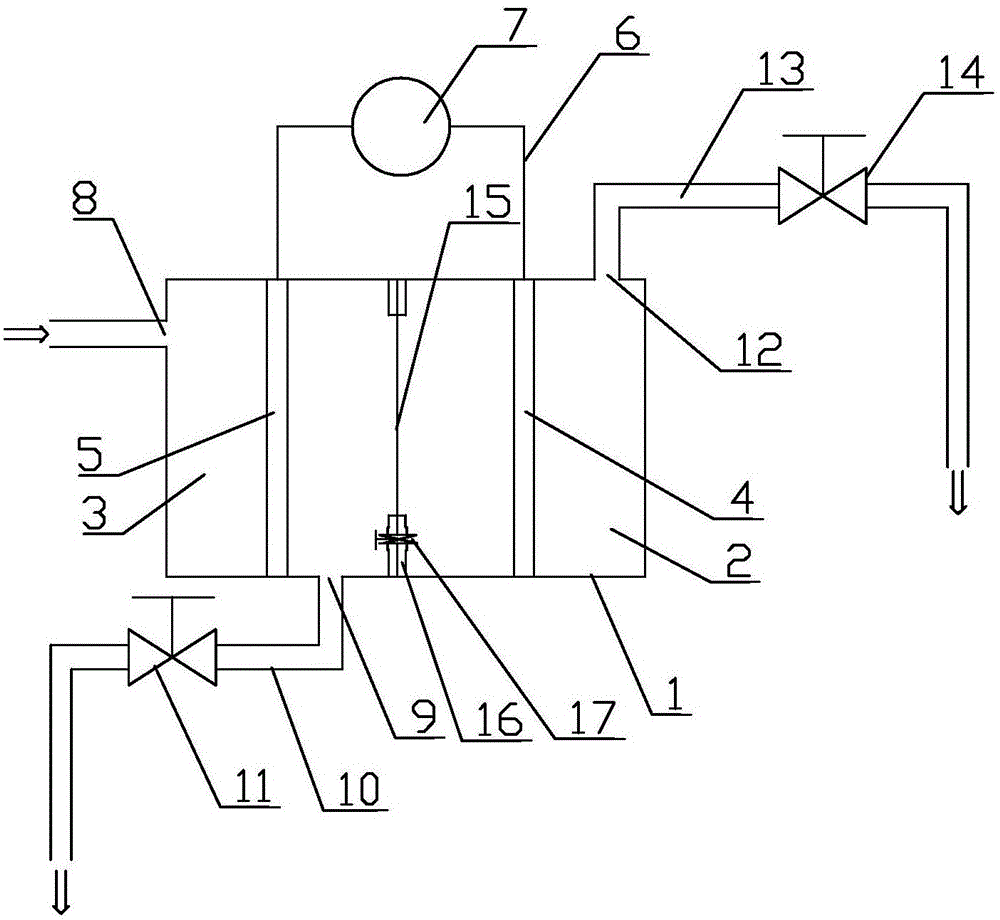

Embodiment 1

[0035] The water production rate of the device was adjusted to 1 L / min, the electrolysis voltage was 10 VDC, and the concentration of the sodium chloride solution was 0.06%. The operation method is as follows: adjust the water production regulating valve 14 to make the water production rate 1L / min, observe the water production index, if pH>6.5; ORP: 100mg / L. Adjust the alkaline water regulating valve 11 to reduce the amount of alkaline water discharge, and at the same time adjust the proportional regulating valve 17 to increase the proportion of alkaline water entering the anode chamber 2. Through repeated adjustments, the water production index is within the acceptable range.

Embodiment 2

[0037] The water production rate of the device was adjusted to 1.5 L / min, the electrolysis voltage was 10 VDC, and the concentration of the sodium chloride solution was 0.06%. On the basis of Example 1, first adjust the water production regulating valve 14 to increase the water production rate to 1.5L / min. At this time, the pH of the production water will increase, the ORP will decrease, and the available chlorine will decrease. To maintain the slightly acidic water index, It is necessary to open the large alkaline water regulating valve 11. At this time, the pH of the produced water will decrease, the ORP will increase, and the available chlorine will increase, so that the pH is between 5.0-6.5, and the ORP>850. Adjust the proportional regulating valve 17 to make the available chlorine at within the qualified range.

Embodiment 3

[0039] On the basis of Example 2, change the electrolysis voltage to 12VDC, and keep the rest unchanged. At this time, the pH will decrease, the ORP will increase, and the available chlorine will increase. To maintain the slightly acidic water index, it is necessary to close the alkaline water regulating valve. 11. Open the large ratio regulating valve 17, close the small water production regulating valve 14, and repeat the adjustment, so that the index of slightly acidic electrolyzed water can be stabilized at the level of Example 2. On the contrary, when the electrolysis voltage adopts 8VDC, the above-mentioned regulating valve can be adjusted in the opposite direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com