A kind of wastewater treatment agent in the middle stage of papermaking

A technology for treating waste water and chemicals in the middle stage of papermaking, which is applied in the direction of waste water treatment in the processing process, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of high cost of chemicals per ton of water treatment, low treatment efficiency, and large amount of sludge. Excellent COD removal rate, speed up the separation process, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

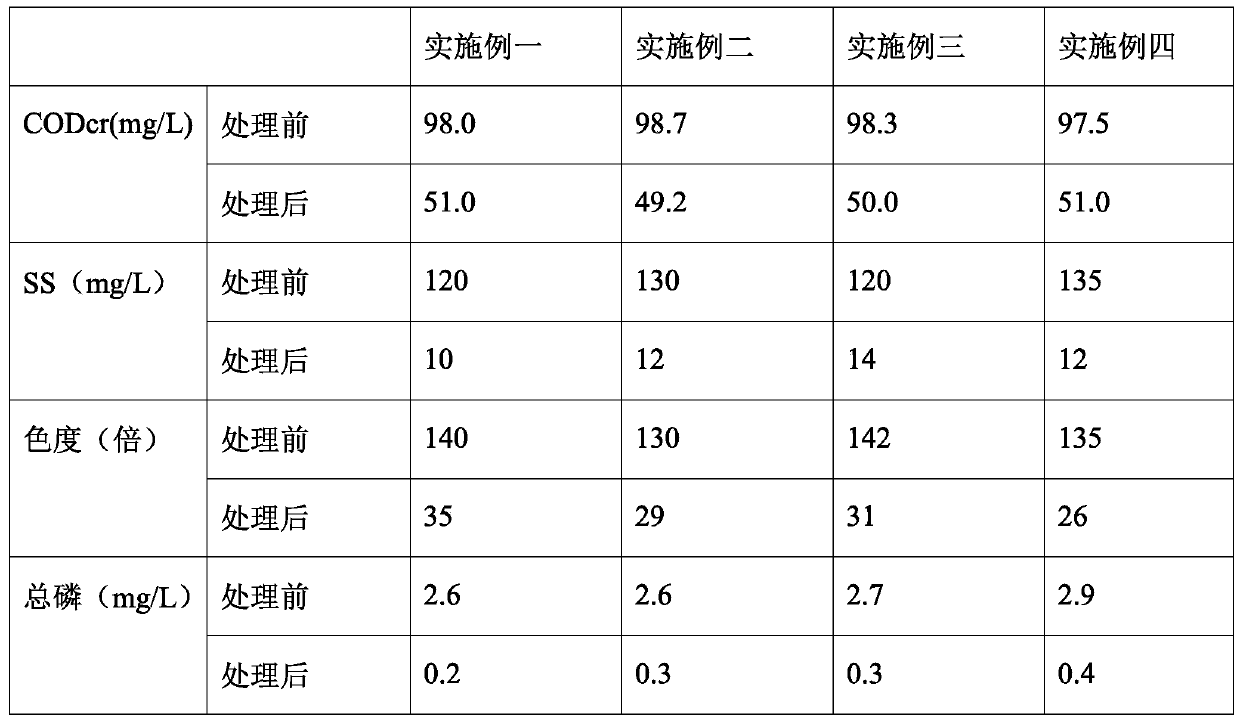

Examples

Embodiment Construction

[0019] In order to make the purpose of the present invention and the advantages of the technical solution more clear, the present invention will be further described in detail below in conjunction with examples.

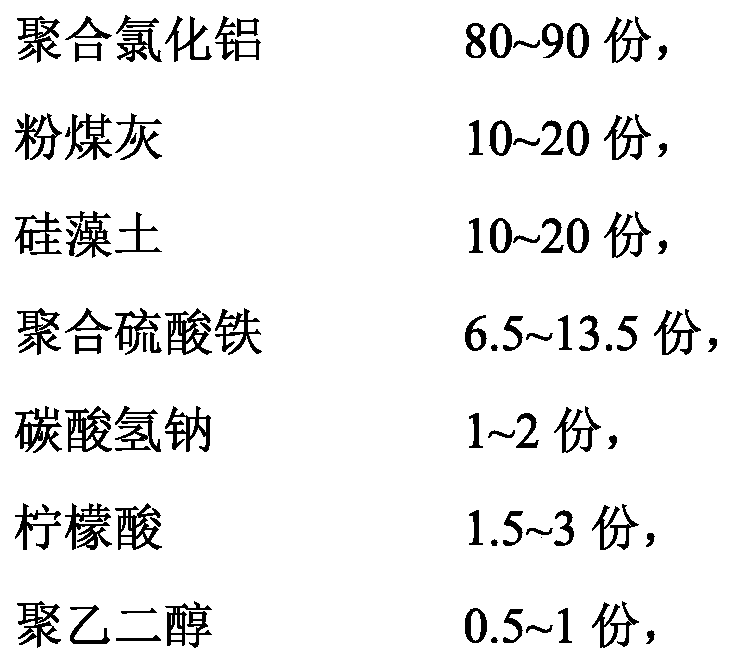

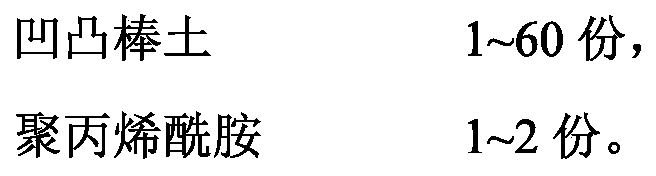

[0020] The preparation process of the wastewater treatment agent in the middle stage of papermaking is as follows:

[0021] Raw material pretreatment

[0022] The fly ash is soaked in 0.6-0.7mol / L hydrochloric acid solution for 10-12 hours, ultrasonically treated at a frequency of 50-100KHz for 2-3 hours, filtered, dried at 100-150°C, ground and crushed to a fineness of 200-300 mesh.

[0023] Diatomite is soaked in 0.2-0.3mol / L hydrochloric acid solution for 10-12 hours, ultrasonically treated at 50-100KHz frequency for 2-3 hours, filtered, roasted at 450-550°C for 2-4 hours, cooled, ground and crushed to a fineness of 200-300 head.

[0024] The molecular weight of polyethylene glycol is 600-4000. After heating and dissolving it, add sodium bicarbonate while stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com