Method of obtaining nontoxic gypsum product and high-arsenic waste residue from contaminated sulfuric acid

A technology of sulfuric acid and gypsum, applied in chemical instruments and methods, calcium/strontium/barium sulfate, water pollutants, etc., can solve the problem of inability to adjust the type and dosage of chemicals, no gypsum arsenic leaching toxicity analysis, poor fluctuation resistance, etc. problems, to achieve the effect of facilitating the stabilization of arsenic slag or resource utilization, strong anti-fluctuation, and strong volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

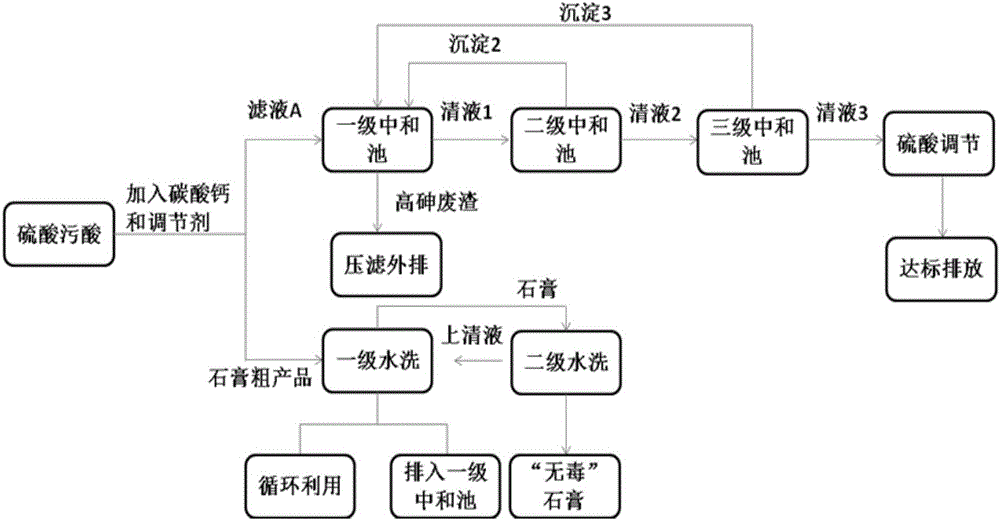

Image

Examples

Embodiment 1

[0049] In this embodiment, the sulfuric acid polluted acid discharged from the sulfuric acid workshop of a certain copper smelter in Hubei is used as the treatment object. The molar concentration of hydrogen ions is 1.42 mol / L, the concentration of sulfate ions is 0.86 mol / L, and the arsenic content is 6.36 g / L.

[0050] A kind of method that obtains nontoxic gypsum product and high-arsenic waste residue from sulfuric acid polluted acid described in the present embodiment, its steps are as follows:

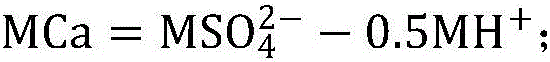

[0051] (1) Removal of sulfate: add 20wt% calcium carbonate suspension and 5.1wt% calcium chloride solution mixed solution to 1L (about 1.01kg) sulfuric acid dirty acid, adjust pH to 1.8, centrifuge after reacting for 0.5h, Obtain gypsum crude product and filtrate A;

[0052] The particle diameter of described calcium carbonate is 300-350 order;

[0053] The consumption of described calcium carbonate is 70g, and the consumption of calcium chloride is 18g, and the output of gypsum ...

Embodiment 2

[0084] In this embodiment, the sulfuric acid polluted acid discharged from the sulfuric acid workshop of a copper smelter in Gansu is used as the treatment object. The molar concentration of hydrogen ions is 0.96 mol / L, the concentration of sulfate ions is 0.75 mol / L, and the arsenic content is 12.9 g / L.

[0085] A kind of method that obtains nontoxic gypsum product and high-arsenic waste residue from sulfuric acid polluted acid described in the present embodiment, its steps are as follows:

[0086] (1) Removal of sulfate radical: add 18wt% calcium carbonate suspension and the mixed solution of 13.6wt% calcium chloride solution to 1L (about 1.01kg) sulfuric acid dirty acid, adjust pH to 1.7, centrifuge after reaction 0.5h, Obtain gypsum crude product and filtrate A;

[0087] The particle diameter of described calcium carbonate is 300-350 order;

[0088] The consumption of described calcium carbonate is 45g, and the consumption of calcium chloride is 34g, and the output of gypsu...

Embodiment 3

[0101] In this embodiment, the sulfuric acid polluted acid discharged from the sulfuric acid workshop of a copper smelter in Anhui is used as the treatment object. The molar concentration of hydrogen ions is 1.0 mol / L, the concentration of sulfate ions is 0.56 mol / L, and the arsenic content is 9.3 g / L.

[0102] A kind of method that obtains nontoxic gypsum product and high-arsenic waste residue from sulfuric acid polluted acid described in the present embodiment, its steps are as follows:

[0103] (1) The removal of sulfate radical: add the mixed solution of 22wt% calcium carbonate suspension and 8.1wt% calcium nitrate solution to 1L (about 1.01kg) sulfuric acid dirty acid, adjust pH to 1.5, centrifuge after reaction 0.5h, get Gypsum crude product and filtrate A;

[0104] The particle diameter of described calcium carbonate is 300-350 order;

[0105] The consumption of described calcium carbonate is 46g, and the consumption of calcium nitrate is 17g, and the output of gypsum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com