Biological treatment device and process for high ammonia-nitrogen pig-raising biogas slurry

A technology for high-ammonia-nitrogen pig-raising biogas and biological treatment is applied in the field of wastewater treatment, which can solve the problems of high ammonia nitrogen biogas slurry treatment cost, difficult operation, and difficulty in popularization, etc., and achieves the effect of improving treatment efficiency, improving the environment, and improving the quality of effluent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

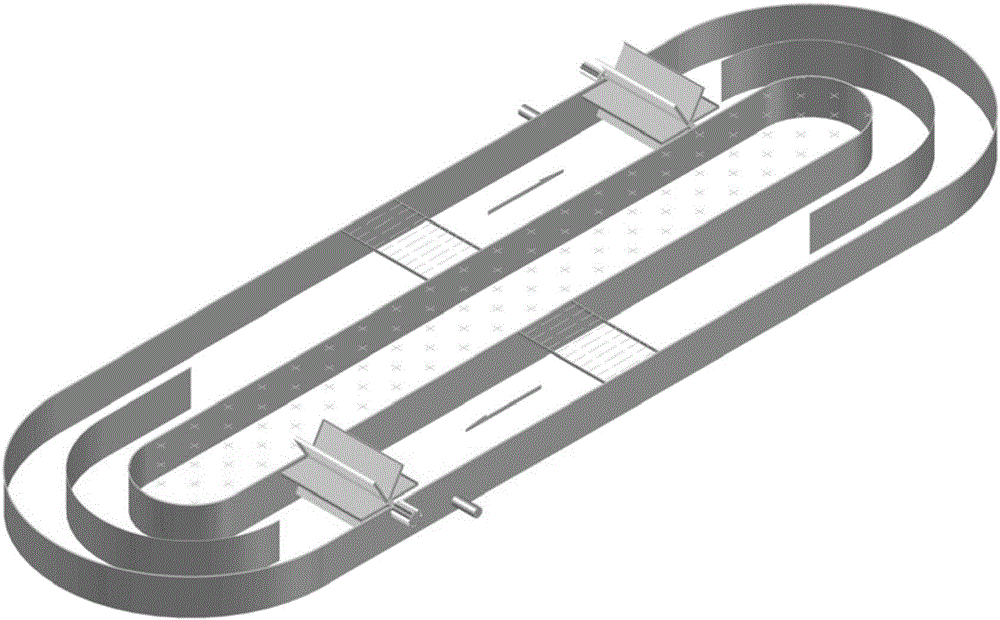

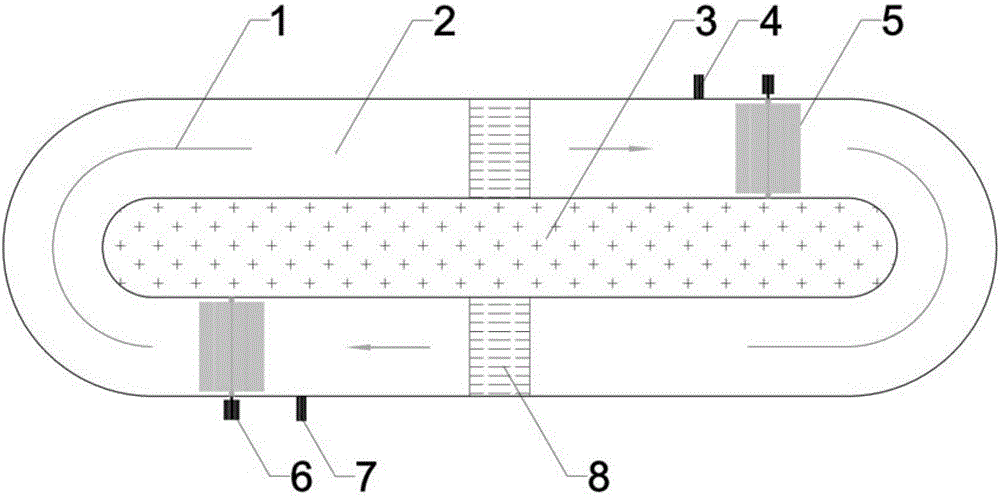

[0032] In the following, taking the treatment process of pig biogas slurry in a large-scale pig farm as an example, the device of the present invention is used to process the biogas slurry.

[0033] The 10 tons of pig farm wastewater is separated into solid and liquid, and the liquid enters the anaerobic fermentation tank for fermentation. After the fermentation, the biogas slurry is temporarily stored in the biogas slurry storage tank. The measured initial COD is 1750mg / L, and the ammonia nitrogen is 320mg / L. Phosphorus is 12mg / L, the pH is 8.4, the ratio of nitrogen to phosphorus, and the pH are within the appropriate range, and can be used directly without adjustment.

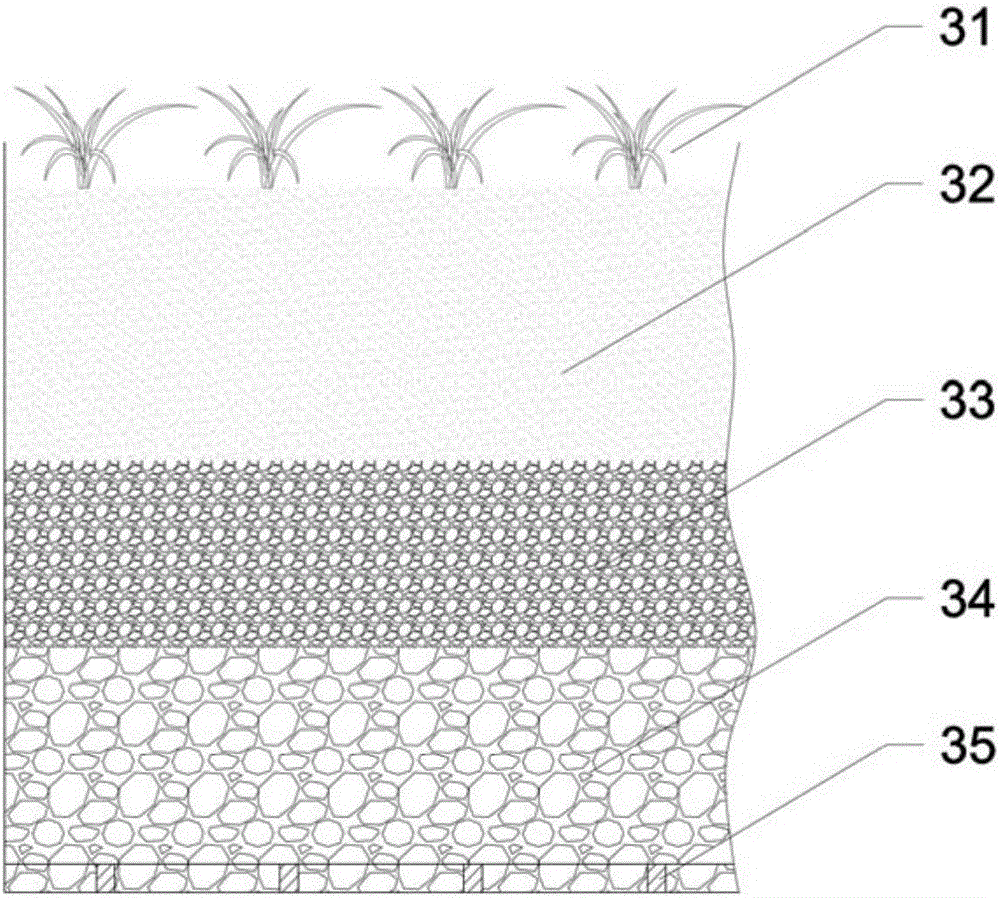

[0034] The biogas slurry enters the reactor through the water inlet. A part of the biogas slurry is treated by photosynthetic bacteria and microalgae in the raceway pond, and is stirred and pushed through the turret; part of the biogas slurry enters the plant area from the support gap, and the biogas slurry is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com