Technology for separating ethyl alcohol-water system by means of extractive distillation and flash coupling

A technology of extractive distillation and extractive distillation tower, which is applied in the field of chemical separation and purification, can solve the problems of affecting product quality, high cost of separation process, complicated process flow, etc., and achieves the reduction of solvent ratio, less addition amount, and increase of relative volatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

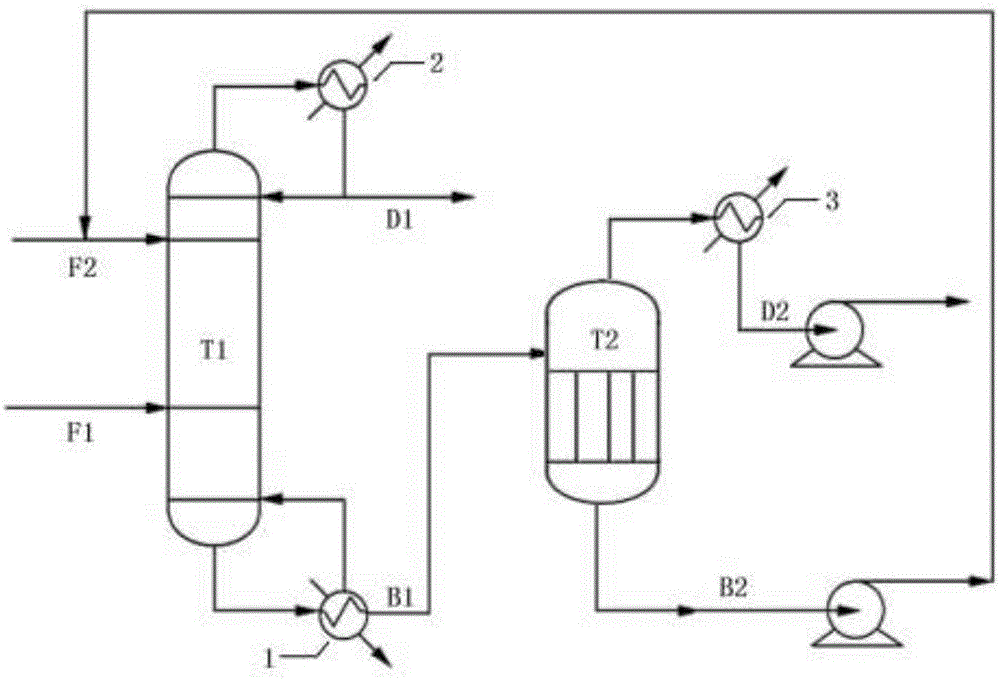

[0023] Example 1: The inner diameter of the extractive distillation tower is Φ500mm, the number of theoretical plates is 40, the operating pressure is 101.325kPa, the operating reflux ratio is 1.8, the temperature at the top of the tower is controlled at 77°C, the temperature at the bottom of the tower is 95°C, and the ions at 25°C The liquid 1-ethyl-3-methylimidazolium tetrafluoroborate enters from the sixth plate, and the mass fraction of 25°C is 20% ethanol-80% water mixture enters from the 34th plate at a flow rate of 1000kg / h. The mass ratio of the ionic liquid to ethanol-water is controlled to be 1:3, and the steam rising from the top of the tower is condensed by the condenser. The reflux liquid is refluxed from the top of the extractive distillation tower, and the production liquid is ethanol with a mass fraction of 99.5%. The tower kettle of the extractive distillation tower is a mixture of 1-ethyl-3-methylimidazolium tetrafluoroborate and water. The reflux liquid is r...

Embodiment 2

[0024] Example 2: The inner diameter of the extractive distillation tower is Φ400mm, the number of theoretical plates is 35, the operating pressure is 101.325kPa, the operating reflux ratio is 2.1, the temperature at the top of the tower is controlled at 77.8°C, the temperature at the bottom of the tower is 109°C, and the ions at 25°C The liquid 1-ethyl-3-methylimidazolium tetrafluoroborate enters from the 6th plate, and the mass fraction of 25°C is 30% ethanol-70% water mixture enters from the 29th plate with a flow rate of 1000kg / h. The mass ratio of ionic liquid to ethanol-water is controlled to be 1:2.5, and the steam rising from the tower top is condensed by the condenser. The reflux liquid is refluxed from the top of the extractive distillation tower, and the production liquid is ethanol with a mass fraction of 99.6%. The tower kettle of the extractive distillation tower is a mixture of 1-ethyl-3-methylimidazolium tetrafluoroborate and water. The reflux liquid is reboile...

Embodiment 3

[0025] Example 3: The inner diameter of the extractive distillation tower is Φ400mm, the number of theoretical plates is 35, the operating pressure is 101.325kPa, the operating reflux ratio is 2.6, the temperature at the top of the tower is controlled at 77.8°C, the temperature at the bottom of the tower is 107°C, and the ions at 25°C The liquid 1-ethyl-3-methylimidazolium tetrafluoroborate enters from the 6th plate, and the mass fraction of 25°C is 40% ethanol-60% water mixture enters from the 30th plate with a flow rate of 1000kg / h. The mass ratio of the ionic liquid to ethanol-water is controlled to be 1:2, and the steam rising from the top of the tower is condensed by the condenser. The reflux liquid is refluxed from the top of the extractive distillation tower, and the production liquid is ethanol with a mass fraction of 99.6%. The tower kettle of the extractive distillation tower is a mixture of 1-ethyl-3-methylimidazolium tetrafluoroborate and water, the reflux liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com