Composition for foam insole and method for producing foam insole using same

A composition and insole technology, which is applied in the field of foam insole manufacturing, can solve the problems of weak peeling strength, complicated bonding process, inability to absorb or discharge, etc., and achieve the effects of preventing feet from slipping, simple bonding process, and improving wearing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

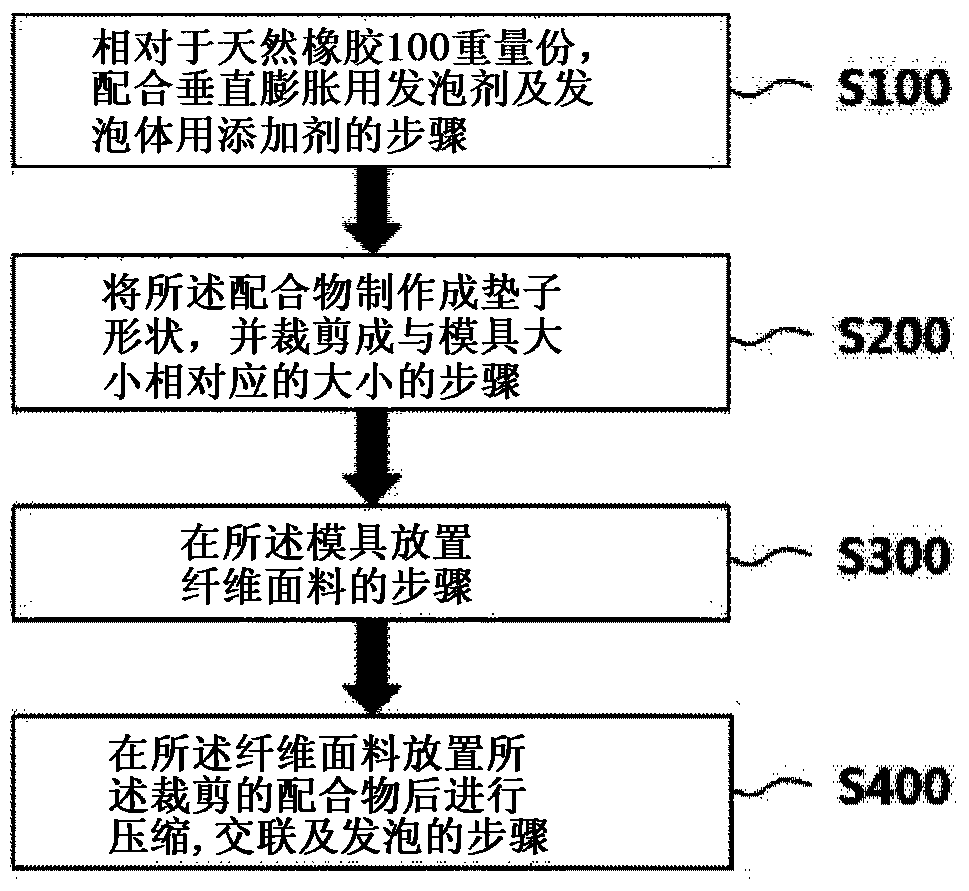

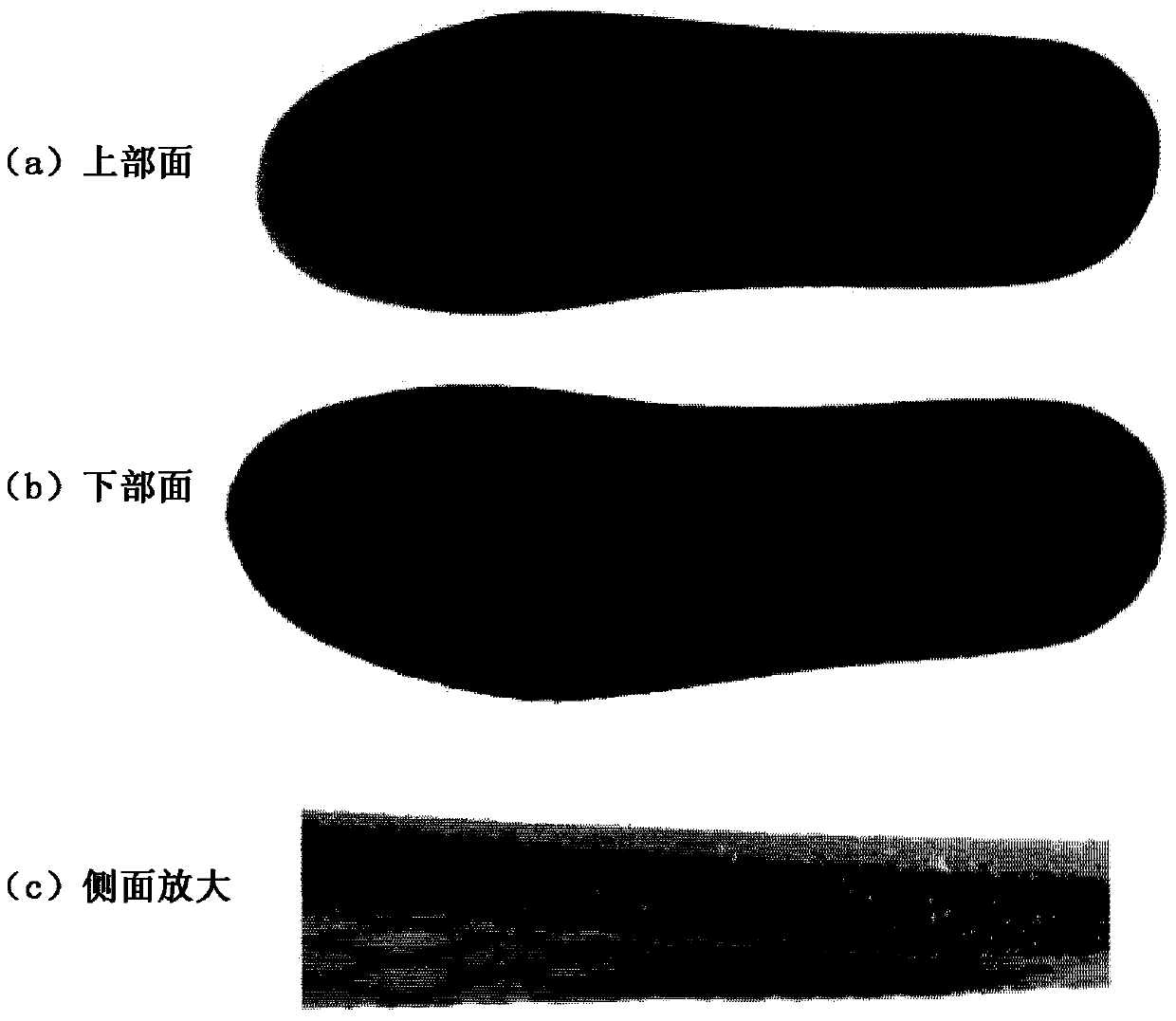

[0045] With respect to 100 parts by weight of natural rubber, 2 parts by weight of zinc oxide, 2 parts by weight of stearate, 10 parts by weight of white carbon black, 5 parts by weight of calcium carbonate, 5 parts by weight of magnesium carbonate, 1 part by weight of 2-mercaptopiperidine catalyst, 1 part by weight of dibenzothiazole disulfide catalyst, 0.1 part by weight of aldehyde amine accelerator, 1 part by weight of processing oil, and 1 part by weight of sulfur as an additive for foam and containing azo Vertical expansion foaming of 1 weight part of diformamide foaming agent, 2 weight parts of flour, 1 weight part of sodium bicarbonate, 2 weight parts of loess, 1 weight part of calcined calcium oxide and 1 weight part of rosin as a homogeneous compounding agent After spraying (S100), use a calender to make a mat shape, and cut it into a size corresponding to the size of the mold (S200), then place the fiber fabric on the mold (S300), place the cut mat on the fiber fabri...

Embodiment 2

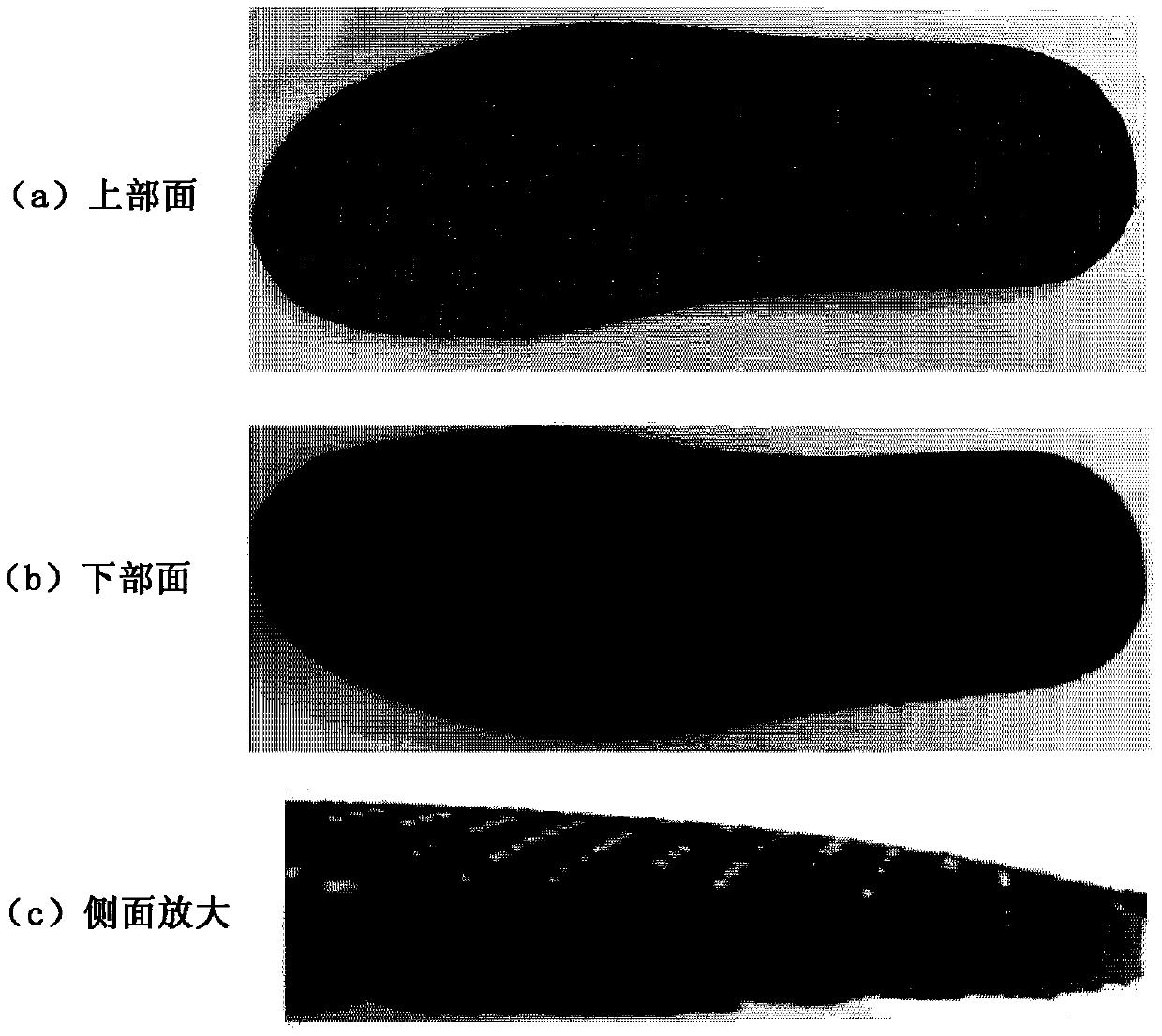

[0047] With respect to 100 parts by weight of natural rubber, 10 parts by weight of zinc oxide, 10 parts by weight of stearate, 50 parts by weight of white carbon black, 20 parts by weight of calcium carbonate, 20 parts by weight of magnesium carbonate, 3 parts by weight of 2-mercaptopiperidine catalyst, 5 parts by weight of dibenzothiazole disulfide catalyst, 5 parts by weight of aldehyde amine accelerator, 10 parts by weight of processing oil, and 3 parts by weight of sulfur additives for foams and azo Vertical expansion foaming of 5 parts by weight of diformamide foaming agent, 20 parts by weight of flour, 10 parts by weight of sodium bicarbonate, 10 parts by weight of loess, 10 parts by weight of calcined calcium oxide and 10 parts by weight of rosin as a homogeneous compounding agent After spraying (S100), use a calender to make a mat shape, and cut it into a size corresponding to the size of the mold (S200), then place the fiber fabric on the mold (S300), place the cut ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com