Hydrophilic type anti-sedimentation far infrared wave-absorbing material and preparation method thereof

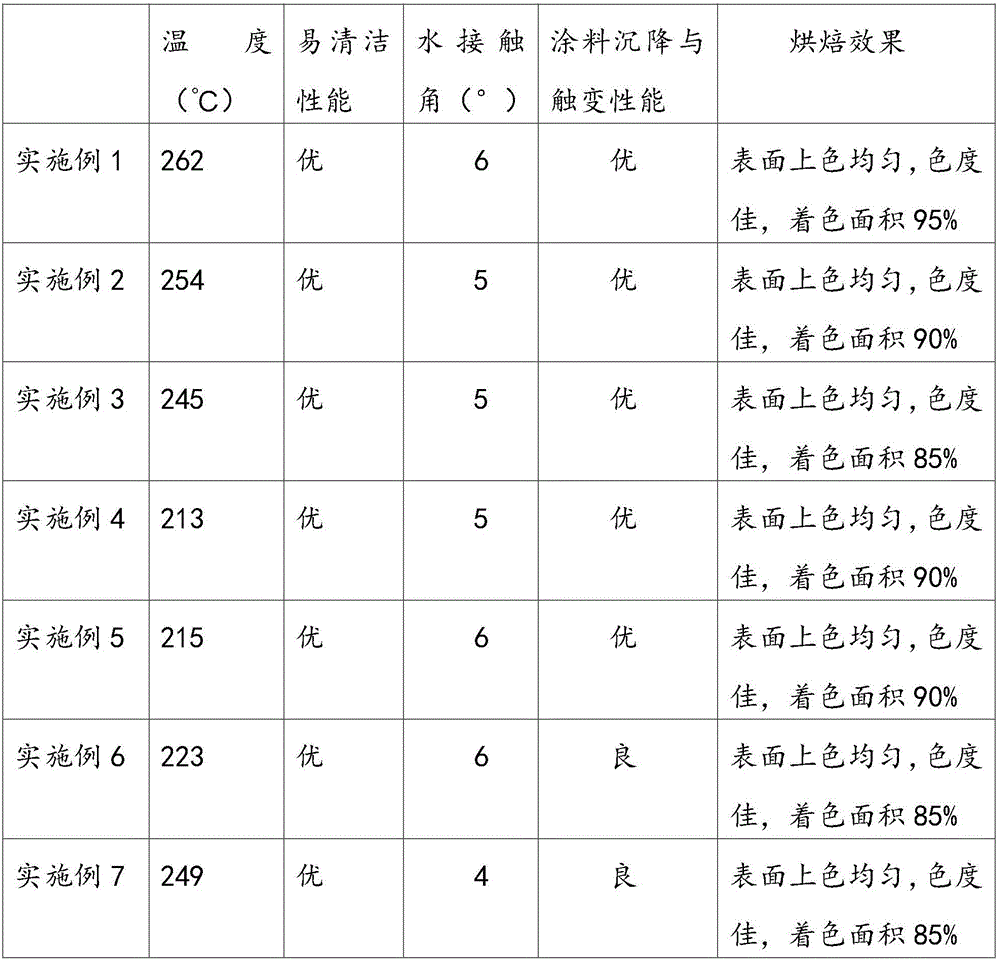

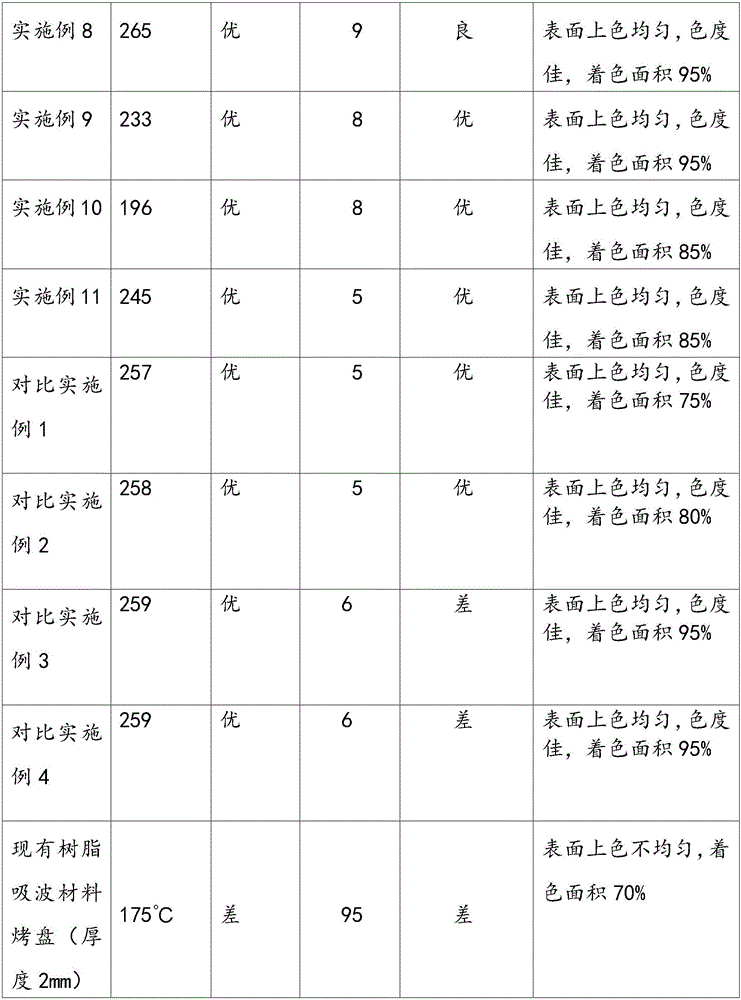

An absorbing material and anti-settling technology, applied in the field of coatings, can solve the problems of large differences in microwave absorbing properties, uneven dispersion of absorbing agents, and no easy cleaning performance, and achieve small differences in microwave absorbing properties and excellent anti- Settling and uniformity, the effect of improving the cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] The invention provides a preparation method of a hydrophilic anti-sedimentation far-infrared wave-absorbing material, which comprises the following steps: mixing each component together according to the above-mentioned proportion.

[0095] Further, said auxiliary agent comprises dispersant, adhesion promoter and defoamer, comprises the following steps:

[0096] 1) Preparation of dispersant-binder mixed system:

[0097] Mix the proportioning amount of binder and part of the dispersing aid according to the proportioning ratio, and mix evenly to obtain a dispersant-binder mixed system;

[0098] 2) Preparation of anti-sedimentation system:

[0099] Add a proportioned amount of anti-settling agent and defoamer to the dispersant-binder mixing system prepared in step 1), and mix evenly to obtain an anti-settling system;

[0100] 3) Preparation of anti-sedimentation absorbing system:

[0101]Adding a wave absorbing agent and an adhesion promoter to the anti-sedimentation sys...

Embodiment 1

[0119] A hydrophilic anti-sedimentation far-infrared wave-absorbing material and its preparation method. The coating consists of: 64.6 kg of binder, 4 kg of wave-absorbing agent, 20 kg of far-infrared powder, and 10 kg of anti-settling agent , the auxiliary agent is 1.4 kg.

[0120] The preparation method is as follows:

[0121] 1) Preparation of dispersant-binder mixed system:

[0122] Mix 64.6 kg of binder (including 15 kg of silica sol, 15 kg of aluminum sol, 6.6 kg of lithium silicate solution, 20 kg of sodium silicate solution and 8 kg of potassium silicate solution) with 0.5 kg of dispersion aid SER-AD FA607 , 300r / min mechanical stirring until the dispersant is completely dissolved and the system is uniform, and the dispersant-binder mixed system is prepared;

[0123] 2) Preparation of anti-sedimentation system:

[0124] Add 8 kilograms of hydrophilic fumed silica A200, 2 kilograms of fumed alumina and 0.3 kilogram of defoamer high-efficiency defoamer JN-5 to the dis...

Embodiment 2

[0131] A hydrophilic type anti-sedimentation far-infrared wave-absorbing material and its preparation method. The coating is composed of: 67.6 kg of binder, 6 kg of wave-absorbing agent, 15 kg of far-infrared powder, and 10 kg of anti-sedimentation agent , the auxiliary agent is 1.4 kg.

[0132] The preparation method is as follows:

[0133] 1) Preparation of dispersant-binder mixed system:

[0134] Mix 67.6 kg of binder (including 25 kg of silica sol, 10 kg of aluminum sol, 5.6 kg of lithium silicate solution, 13 kg of sodium silicate solution and 14 kg of potassium silicate solution) with 0.5 kg of dispersing aid BYK-301, Stir mechanically at 300r / min until the dispersant is completely dissolved and the system is uniform to obtain a dispersant-binder mixed system;

[0135] 2) Preparation of anti-sedimentation system:

[0136] Add 8 kilograms of hydrophilic fumed silica A200, 2 kilograms of fumed alumina and 0.3 kilogram of defoamer high-efficiency defoamer JN-5 to the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com