Skid-mounted oil sludge pyrolysis treatment system and application thereof

A treatment system, skid-mounted technology, applied in pyrolysis treatment of sludge, water/sludge/sewage treatment, petroleum industry, etc., to achieve high treatment efficiency, reduced transportation costs, and improved treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

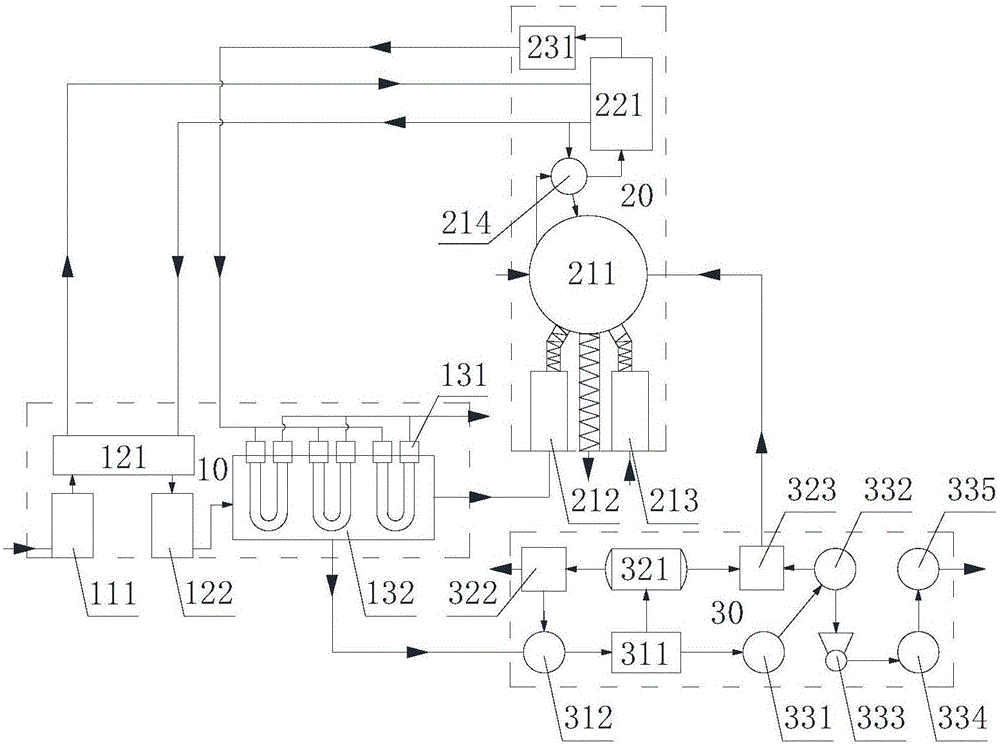

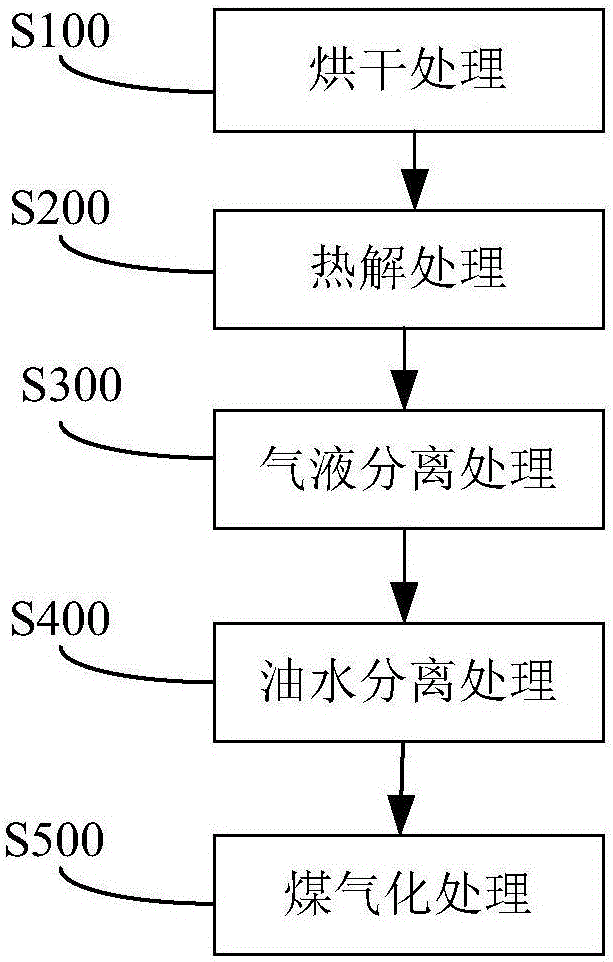

Image

Examples

Embodiment 1

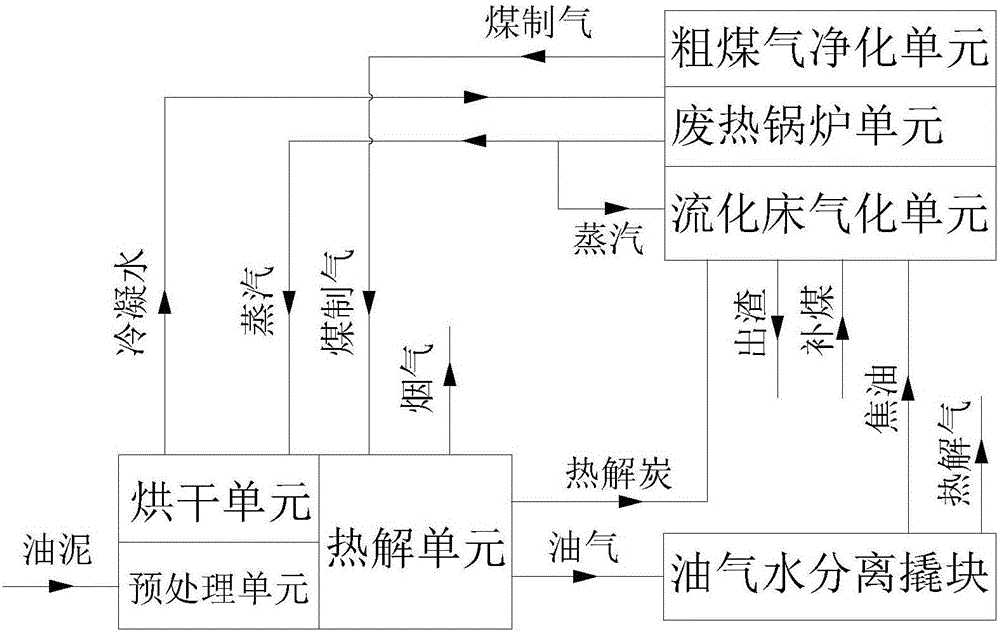

[0078] Utilize the skid-mounted oily sludge pyrolysis treatment system of the embodiment of the present invention to process oily sludge, the system processing flow is as follows image 3 As shown, the processing capacity of the system is 5t / h, and the pyrolysis products include gas, liquid and solid. After the oil, gas and water separation skid, the yield calculated by the meter data is as follows:

[0079] Table 1 pyrolysis product yield

[0080]

[0081] The purified pyrolysis gas is stored in the gas cabinet, and the process gas is taken and analyzed during the temperature change process. The composition of the pyrolysis gas is as follows:

[0082] Table 2 Composition analysis of pyrolysis gas

[0083]

[0084] The composition of pyrolytic charcoal after pyrolysis is analyzed, and the results are as follows:

[0085] Table 3 Residue Analysis Results

[0086]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com