Method of preparing biological flocculant from cornstalks

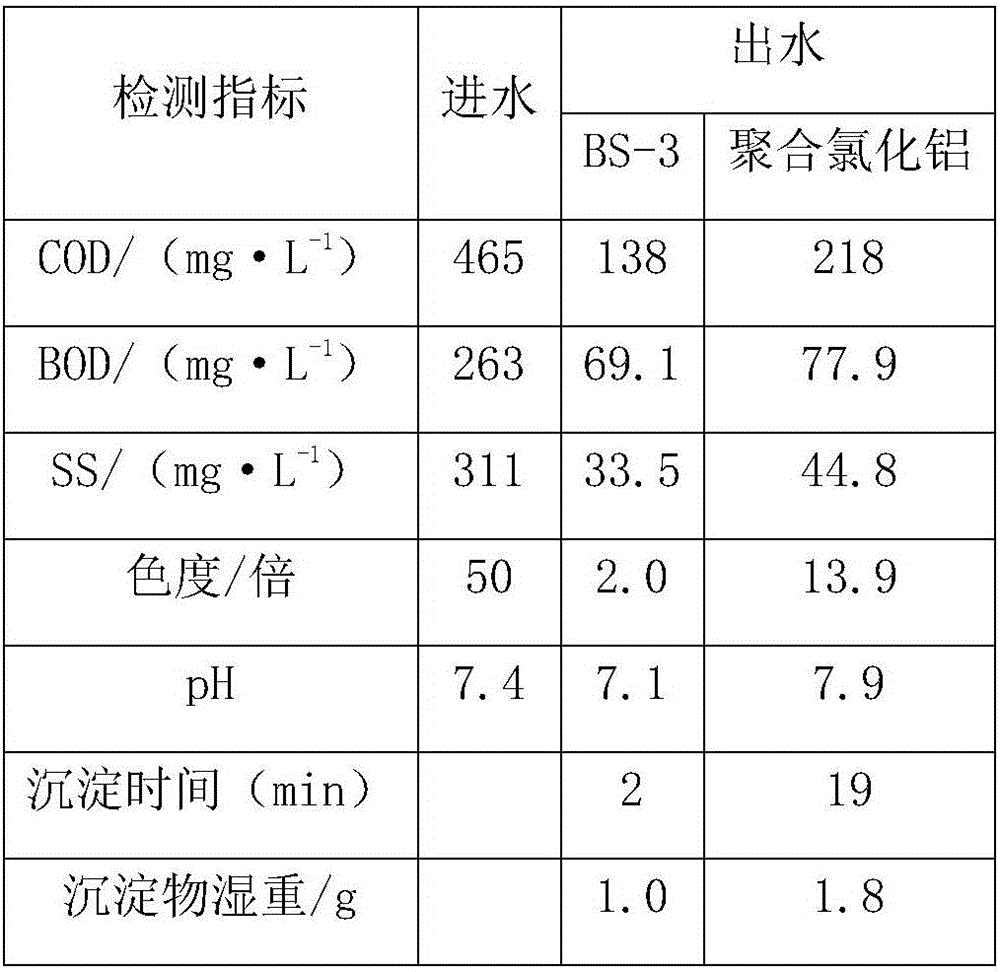

A technology of biological flocculants and corn stalks, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high treatment cost, large waste water, serious environmental pollution, etc., and reduce process energy consumption and process Discharge of waste water, effect of increasing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

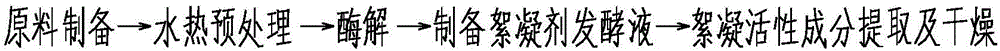

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: comprise the following steps:

[0040] S1. Preparation of raw materials: After the corn stalks are naturally air-dried, the air-dried corn stalks are crushed and sieved by a pulverizer, and the parts with a particle size of 35 mesh are screened out, put into a vacuum drying oven, and dried at a temperature of 100°C. The dried raw materials are stored in a desiccator for subsequent use;

[0041] S2, hydrothermal pretreatment:

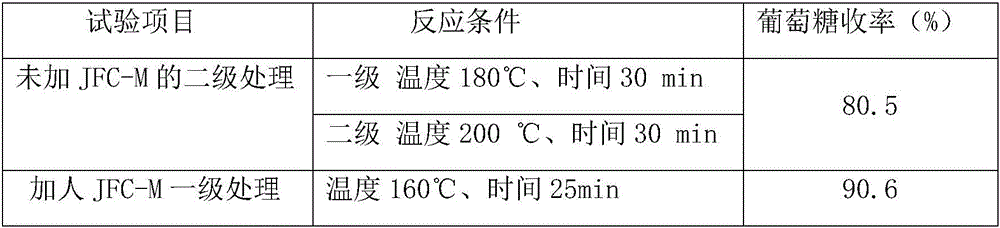

[0042] S2.1: Take 20g of dried raw material and add it to 400mL of deionized water, then add the catalyst FeCl 31.0g and 20ml of high-temperature penetrant JFC-M solution with a concentration of 6mg / mL were mixed and added to the reaction kettle, and the reaction kettle was sealed;

[0043] S2.2: Stir with a magnetic stirrer, adjust the speed of the magnetic stirrer to 260r / min, start heating, when the temperature is 160°C, keep the constant temperature for 20min, and perform hydrothermal pretreatment;

[0044] S2.3: After the p...

Embodiment 2

[0065] 1. Raw material preparation and hydrothermal treatment process:

[0066] After the raw corn stalks are naturally air-dried, the air-dried corn stalks are crushed and sieved by a material grinder, and the parts with a particle size of 40 mesh are screened out, put into a vacuum drying oven, and dried at a temperature of 105°C. The raw materials are stored in a desiccator for future use.

[0067] The specific steps of hydrothermal pretreatment of corn stalks are as follows:

[0068] (1) The solid-to-liquid ratio used in the pretreatment experiment is 5% (wt), that is, take 21g dry corn stalk samples and 410mL deionized water, add catalyst FeCl 3 1.1g and high-temperature penetrant JFC-M solution 21ml (JFC-M solution with a concentration of 6mg / mL), mix and add to a 1000mL reaction kettle, and seal the reaction kettle;

[0069] (2) Turn on the total power supply, controller power supply, and display power supply of the experimental device in turn, set the pretreatment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com