Chemically cross-linked modified silk fibroin/alginate composite fiber and preparation method thereof

A technology of silk fibroin and chemical cross-linking, which is applied in the fields of spinning solution preparation, cellulose/protein conjugated artificial filament, fiber chemical characteristics, etc., can solve the limited application range, insufficient mechanical properties of pure sodium alginate fiber, etc. problem, to achieve the effects of obvious enhancement effect, increased practicality and added value, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

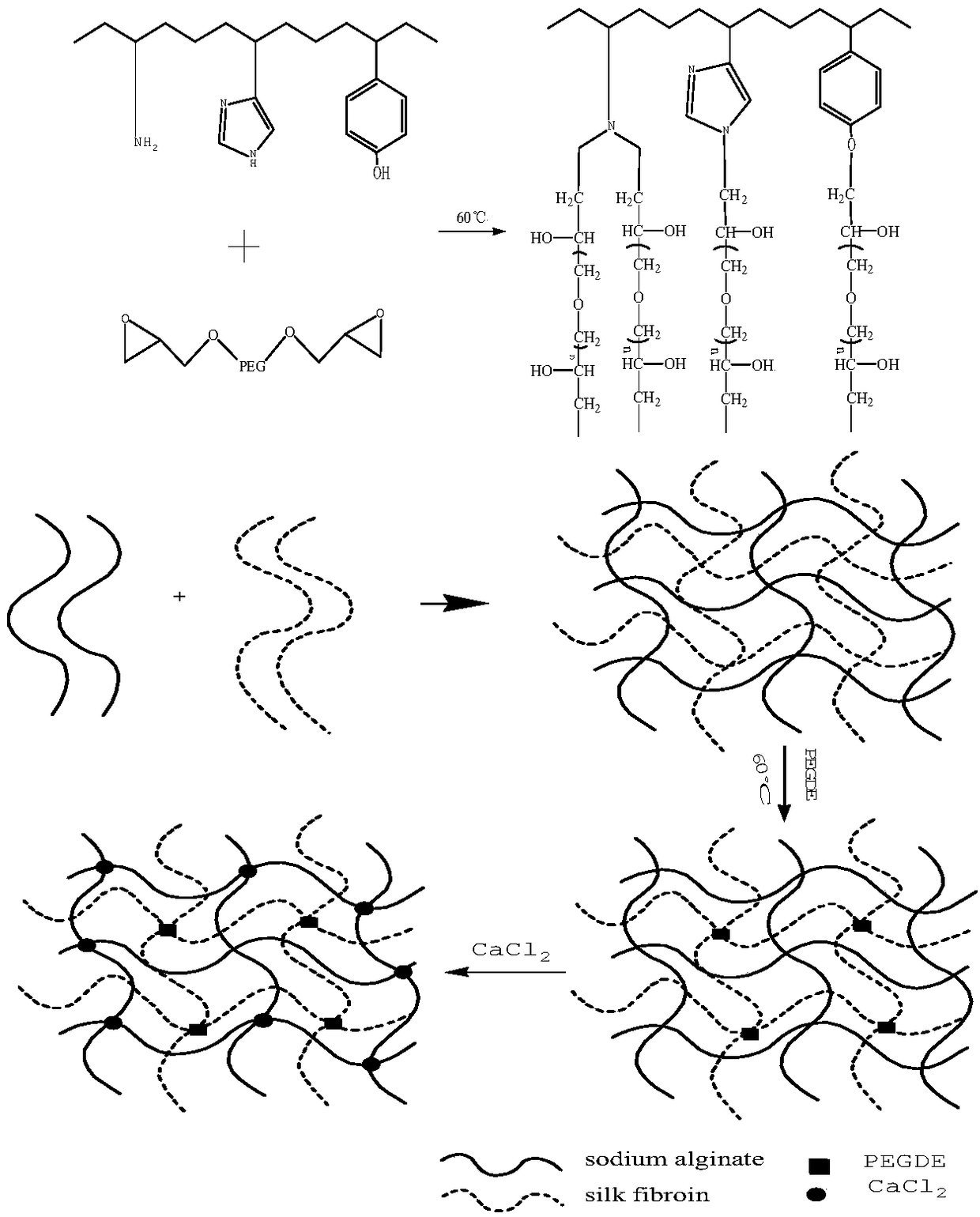

[0024] This example discloses a chemically cross-linked modified silk fibroin / alginate composite fiber, which is prepared by the following method:

[0025] Put the shredded cocoons into 0.5% NaCO 3 In the solution, degumming was carried out three times in water at 100° C. for 30 minutes each time, and the silk fiber was obtained after drying. Prepare a mixed solution of calcium chloride, ethanol, and water (molar ratio 1:2:8), dissolve silk fibers at 70°C, and obtain a silk fibroin solution after dialysis and centrifugation.

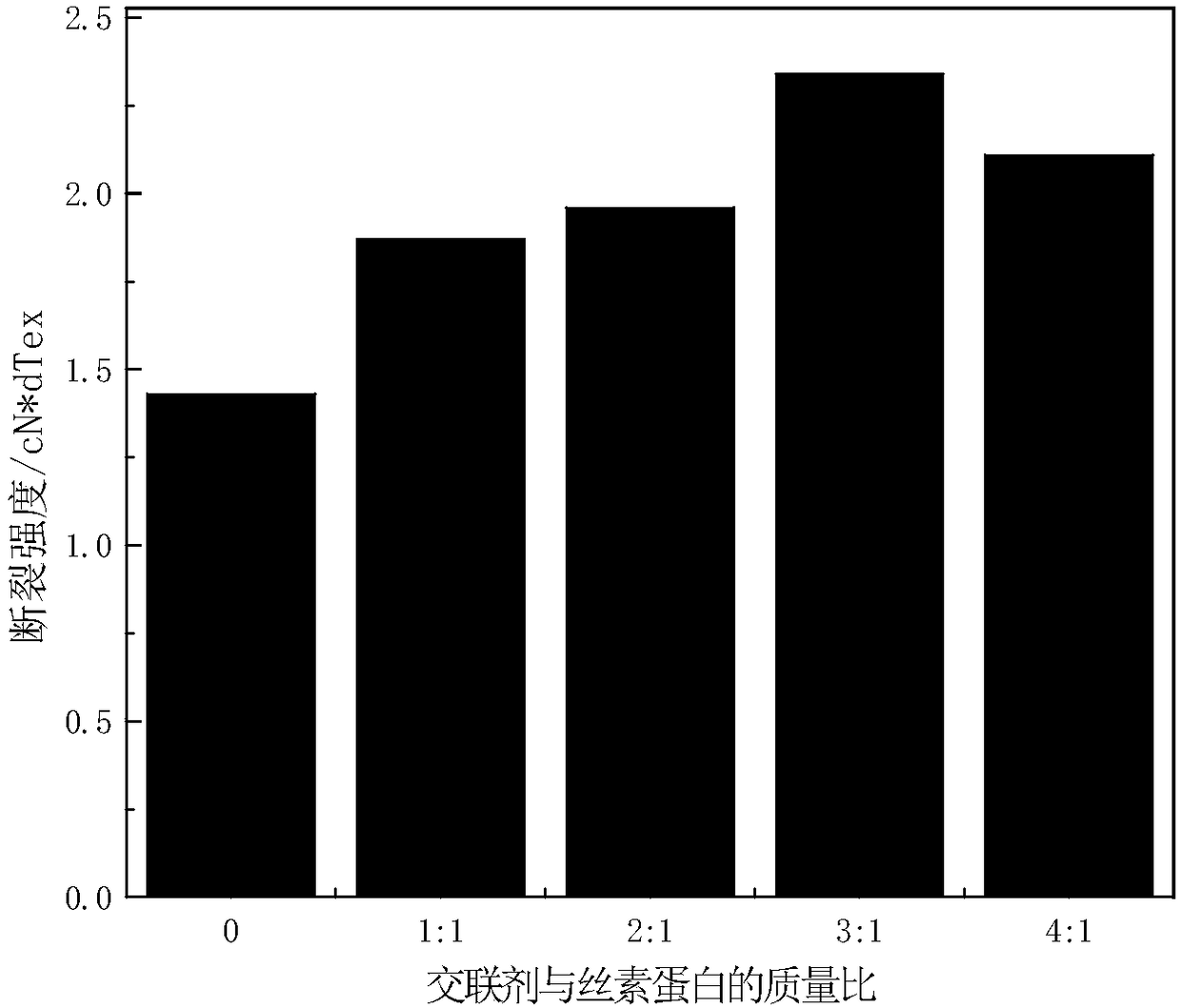

[0026] Dissolve 2g of sodium alginate in a certain amount of water to prepare a sodium alginate solution with a mass concentration of 2%. According to the solid mass ratio of silk fibroin and sodium alginate as 1:10, mix the mass concentration of 4.5% silk fibroin solution and seaweed Mix sodium acid solution, add 0.2g polyethylene glycol diglycidyl ether, mechanically stir and react for 60min in water at 60°C, after the reaction is completed, let it st...

Embodiment 2

[0032] This example discloses a chemically cross-linked modified silk fibroin / alginate composite fiber, which is prepared by the following method:

[0033] Put the shredded cocoons into 0.5% NaCO 3In the solution, degumming was carried out three times in water at 100° C. for 30 minutes each time, and the silk fiber was obtained after drying. Prepare a mixed solution of calcium chloride, ethanol, and water (molar ratio 1:2:8), dissolve silk fibers at 70°C, and obtain a silk fibroin solution after dialysis and centrifugation. Dissolve 2g of sodium alginate in a certain amount of water to prepare a sodium alginate solution with a mass concentration of 2%. The mass ratio of silk fibroin and sodium alginate at a mass concentration of 4.5% is 1:10, and the silk fibroin solution and Sodium alginate solution was mixed, 0.4g polyethylene glycol diglycidyl ether was added, mechanically stirred and reacted in water at 60°C for 60 minutes, after the reaction was completed, it was allowed...

Embodiment 3

[0036] This example discloses a chemically cross-linked modified silk fibroin / alginate composite fiber, which is prepared by the following method:

[0037] Put the shredded cocoons into 0.5% NaCO 3 In the solution, degumming was carried out three times in water at 100° C. for 30 minutes each time, and the silk fiber was obtained after drying. Prepare a mixed solution of calcium chloride, ethanol, and water (molar ratio 1:2:8), dissolve silk fibers at 70°C, and obtain a silk fibroin solution after dialysis and centrifugation. Dissolve 2g of sodium alginate in a certain amount of water to configure a sodium alginate solution with a mass concentration of 2%. According to the solid mass ratio of silk fibroin and sodium alginate as 1:10, mix the silk fibroin solution with a mass concentration of 4.5% and Mix the sodium alginate solution, add 0.6g of polyethylene glycol diglycidyl ether, mechanically stir and react for 60 minutes in water at 60°C, after the reaction is completed, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com