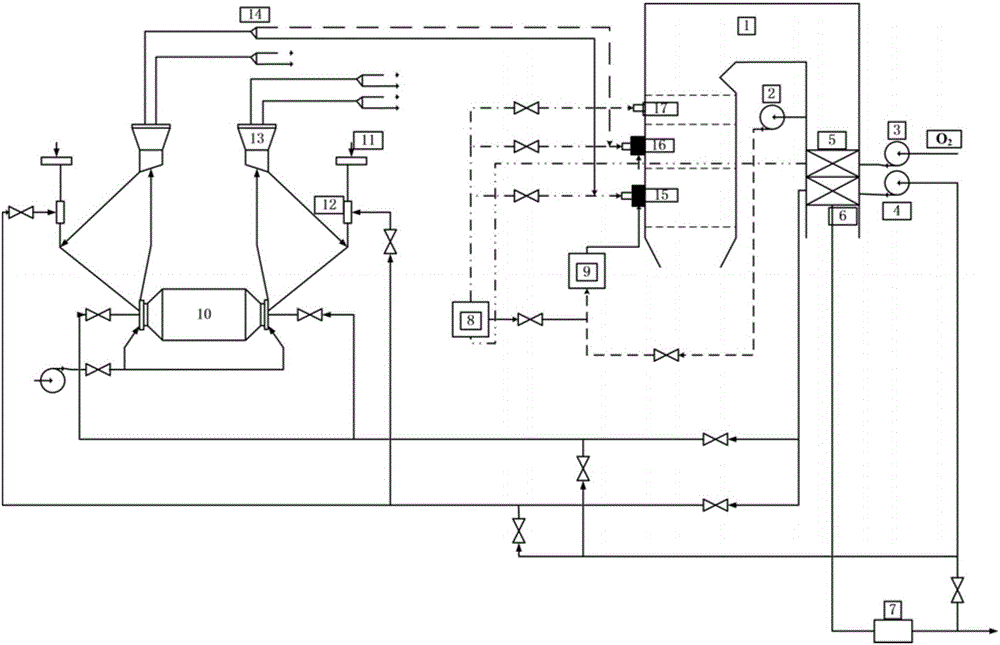

Anthracite large oxygen-enriched combustion system and method with novel direct blowing powder production device

A pulverizing device and oxygen-enriched combustion technology, which is applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of large consumption, high cost, and complicated debugging, so as to achieve CO2 emission reduction, improve ignition characteristics, The effect of increasing the burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiment of the present invention provides a large-scale anthracite oxygen-enriched combustion system and method with a new type of direct-blowing pulverizing device, which realizes a tangential combustion method or a wall combustion method for burning anthracite with a large capacity (600MW and above). When using the direct-blown pulverizing system, the temperature of the primary air powder is low. This system optimizes the air flow of the primary air powder and improves its ignition characteristics. This combustion method achieves CO 2 Emission reduction fundamentally reduces the emission of nitrogen oxides and at the same time improves the burnout rate of pulverized coal.

[0037] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com