High-temperature generator for lithium bromide cold and warm water unit and pipe expanding method

A technology of cold and warm water unit and high temperature generator, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve problems such as damage, decreased heat transfer capacity, stainless steel intolerance, etc., to reduce the difficulty factor and improve the service life. , Improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

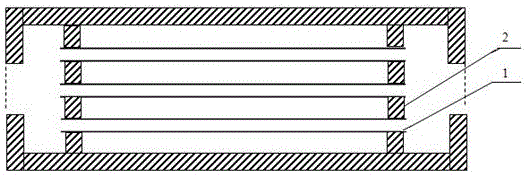

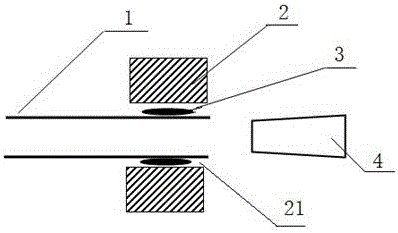

[0024] Such as figure 1 and figure 2 Shown: a high-temperature generator for a lithium bromide cold and warm water unit, including a tube plate 2 and a heat exchange tube, the heat exchange tube is inserted into the hole 21 of the tube plate 2; the heat exchange tube is titanium heat exchange tube 1, titanium heat exchange tube 1 The outside of the tube end is coated with simethicone 3, and the coating thickness of simethicone 3 is 0.05mm. The titanium heat exchange tube 1 is made of pure titanium.

[0025] The use of titanium heat exchange tube 1 in this embodiment has the following advantages: (1) Titanium has no corrosion in the use environment and is durable; (2) The thermal expansion coefficient of titanium is less than that of carbon steel used as a high-temperature generator shell 10%, the shell and heat exchange tubes expand consistently during work, and there is no hidden danger of stress damage; (3) The strength of titanium is close to that of stainless steel, and...

Embodiment 2

[0033] The difference from Example 1 is that the simethicone oil is coated in the holes of the tube sheet, and the coating thickness is 0.1 mm.

[0034] Others are with embodiment 1.

Embodiment 3

[0036] The difference from Example 1 is that the simethicone oil is coated not only in the hole of the tube sheet, but also on the outside of the tube end of the titanium heat exchange tube, and the coating thickness in the hole of the tube sheet is 0.02 mm. The coating thickness on the outside of the tube end of the heat exchange tube was 0.08 mm.

[0037] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com