Nickel colloid catalyst solution for electroless nickel or nickel alloy plating, and electroless nickel or nickel alloy plating method

A technology of electroless nickel plating and nickel alloy, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as chemical plating not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 13

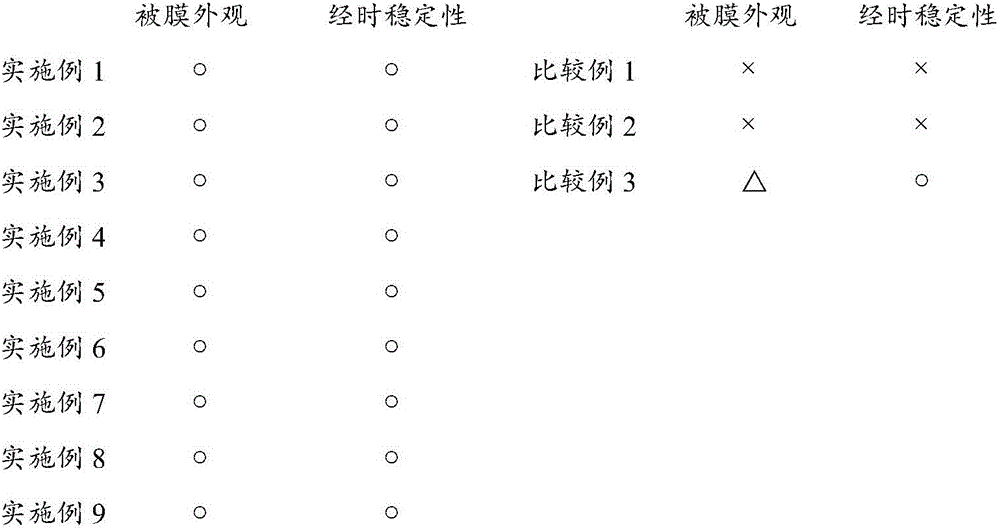

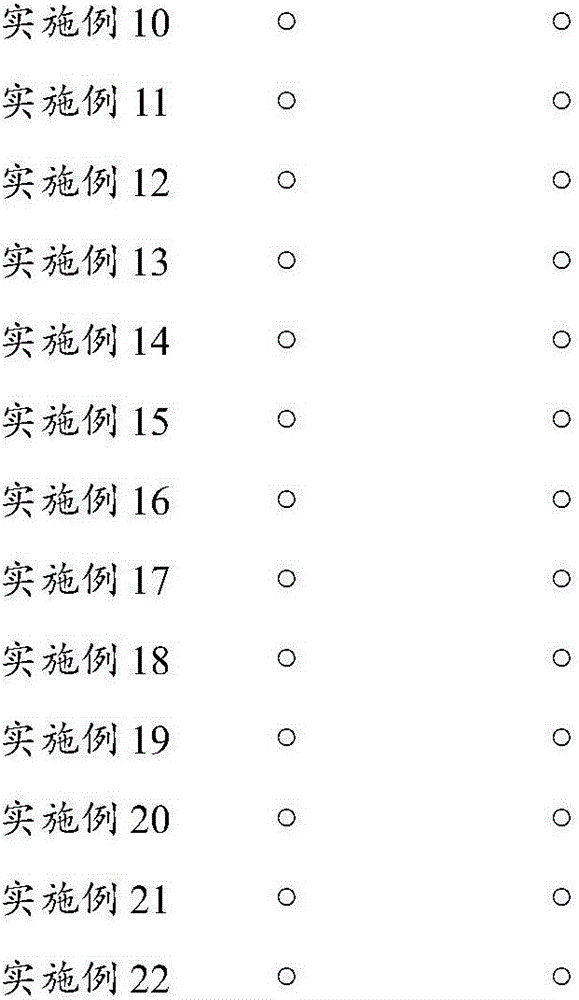

[0130] Examples 13 to 14 are based on Example 9, Example 13 is an example of changing the type of nickel salt, and Example 14 is an example of using a borohydride compound and hypophosphorous acid as a reducing agent.

[0131] In addition, as mentioned above, Examples 21 to 22 are examples of the electroless nickel-cobalt alloy plating method. Among them, in Example 21, after the pretreatment process of decontamination and neutralization, the adsorption promotion→catalyst application→chemical Each process of the coating film, the pretreatment process, the adsorption promotion process, and the catalyst application process are based on the above-mentioned Example 1. Embodiment 22 is based on the above-mentioned embodiment 21, and is an example in which the nickel colloid catalyst solution is changed from embodiment 1 to the catalyst solution of embodiment 18.

[0132]On the other hand, among the following Comparative Examples 1 to 3, Comparative Example 1 is a blank example in w...

Embodiment 1

[0134] The electroless nickel plating method of the present invention is characterized in that the steps of adsorption promotion→catalyst application→electroless plating are sequentially carried out, and this Example 1 is an example of further performing the pretreatment steps of decontamination and neutralization before the adsorption promotion step.

[0135] That is, after pretreatment under the following condition (p), adsorption promotion is performed under condition (a), catalyst application is performed under condition (b), and then electroless nickel-phosphorus plating is performed under condition (c).

[0136] (p) Pretreatment process

[0137] First, on a double-sided copper-clad glass-epoxy resin substrate (FR-4 manufactured by Panasonic Electric Works Co., Ltd., thickness: 1.0 mm), remove 35 μm of copper foil by dissolving and desmearing / neutralizing substrate as the sample substrate.

[0138] The compositions of the desmutting treatment liquid and the neutralizatio...

Embodiment 2

[0175] Based on above-mentioned embodiment 1, prepare nickel colloidal catalyst liquid according to following composition, except that, the preparation method of nickel colloidal catalyst liquid and electroless nickel plating liquid and the processing condition of each operation are set to be identical with embodiment 1.

[0176] (b) Preparation of nickel colloidal catalyst solution

[0177] [nickel solution]

[0178] Nickel sulfate (as Ni 2+ 0.1 mol / L): 0.1 mol / L

[0179] Citric acid: 0.15 mol / L

[0180] [reducing agent solution]

[0181] Sodium borohydride: 0.2 mol / L

[0182] [Preparation conditions of nickel colloidal catalyst solution]

[0183] Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com