Gas filter foam with graphene oxide and preparation method thereof

A technology of filter cotton and graphene, which is applied in the field of materials science, can solve problems such as poor results, achieve significant technological progress, improve adsorption performance, and increase specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

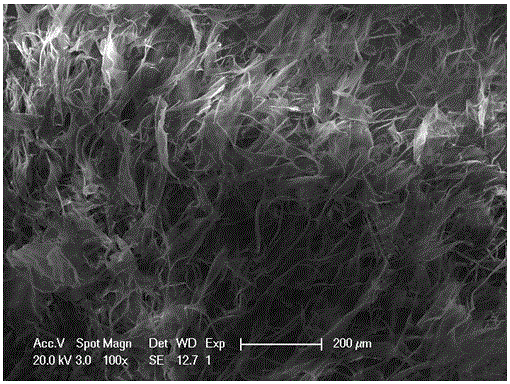

Image

Examples

Embodiment 1

[0031] (1) Preparation of graphene oxide: mix 0.5g of natural flake graphite with 50ml of concentrated sulfuric acid / concentrated phosphoric acid with a volume ratio of 9:1 in a high-pressure reactor, and slowly add 4g of high Potassium manganate, seal the reactor, heat up to 80°C and react for 3 hours, then cool to room temperature, take the product out of the reactor and dilute to 200ml, then add 10ml of hydrogen peroxide to obtain a bright yellow graphite oxide solution; then use a mass fraction greater than 5% After washing with dilute hydrochloric acid for 5 times, centrifuge and wash with deionized water until the pH of the supernatant is 5-7, ultrasonically disperse graphite oxide for 2 hours, and the ultrasonic power is 200W. Obtain graphene oxide dispersion liquid;

[0032] (2) Impregnated filter cotton: The activated carbon filter cotton is soaked in the dispersion liquid with a concentration of 0.01mg / ml, and the dispersion liquid is submerged in the synthetic fiber...

Embodiment 2

[0036] (1) prepare graphene oxide: take embodiment 1 to obtain graphene oxide dispersion;

[0037] (2) Impregnated filter cotton: The non-woven filter cotton is soaked in the dispersion liquid with a concentration of 0.1mg / ml, and the dispersion liquid is submerged in the synthetic fiber filter cotton.

[0038] (3) Freezing: The impregnated filter cotton obtained in step (2) is placed in the freezing chamber of a freeze dryer, and solidified at -50°C.

[0039] (4) Drying: vacuumize, the vacuum degree is less than 10Pa, sublimate the solvent at room temperature, and obtain graphene oxide filter cotton.

Embodiment 3

[0041] (1) prepare graphene oxide: take embodiment 1 to obtain graphene oxide dispersion;

[0042] (2) Impregnated filter cotton: soak the glass fiber filter cotton in the dispersion liquid with a concentration of 1mg / ml, and the dispersion liquid is submerged in the synthetic fiber filter cotton.

[0043] (3) Freezing: The impregnated filter cotton obtained in step (2) is placed in the freezing chamber of a freeze dryer, and solidified at -20°C;

[0044] (4) Drying: vacuumize, the vacuum degree is less than 10Pa, sublimate the solvent at room temperature, and obtain graphene oxide filter cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com