Dry surface-mortar additive material and preparation method thereof

A technology of plastering mortar and additives, which is applied in the field of architectural coatings and can solve the problems of poor waterproof and antifreeze performance and low bonding strength of plastering mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

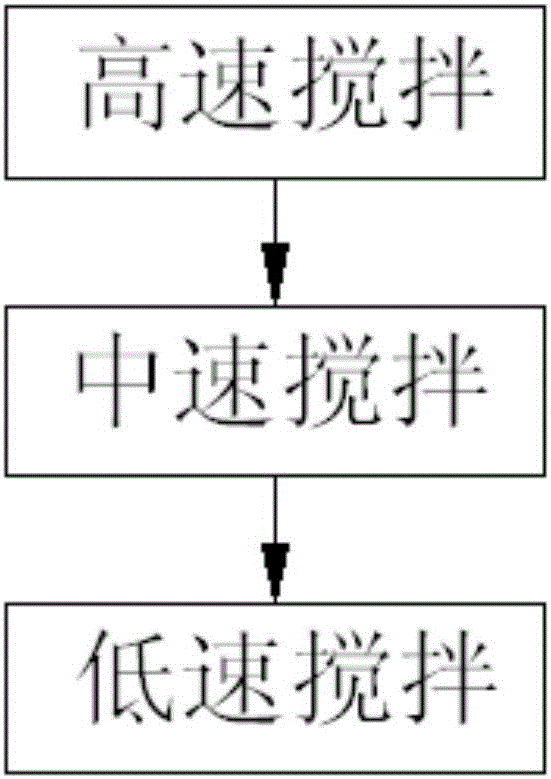

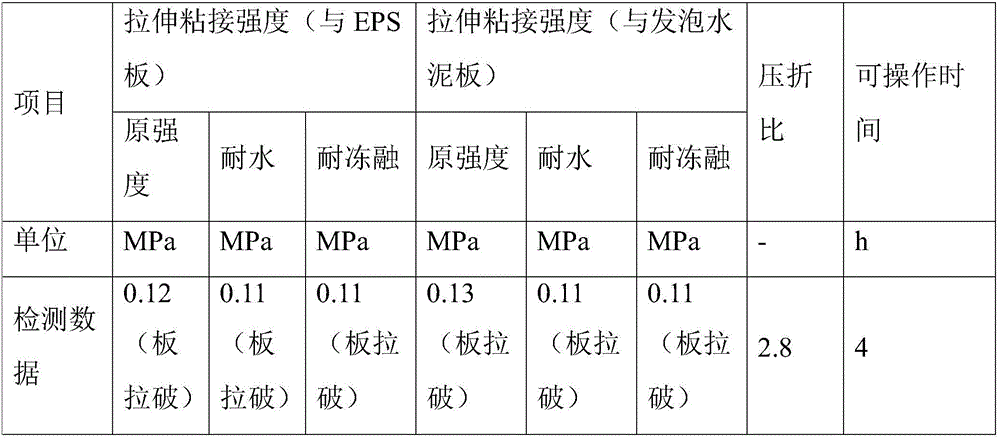

[0016] Such as figure 1 As shown, the present invention provides a dry mortar additive dry material, which comprises the following components: 2 kg of hydroxypropyl methylcellulose with a viscosity of 80,000 to 120,000, redispersible latex powder 10kg, 0.3kg for silicone water repellent, 0.5kg for starch ether, 0.5kg for calcium formate, 1kg for polycarboxylate superplasticizer with polyester structure, 2kg for polyvinyl alcohol 2488, and 2kg for modified wood fiber 2kg, the modified PVAC is 2kg. When preparing the dry material of the plastering mortar additive, a variable speed mixer is used for variable speed mixing. First, the modified wood fiber and the polycarboxylate water reducer are stirred at high speed for 3 minutes, and then the silicone water-repellent is added. After stirring at a medium speed for 3 minutes, finally add hydroxypropyl methylcellulose, redispersible latex powder, starch ether, calcium formate, polyvinyl alcohol, and modified PVAC and stir at a low s...

Embodiment 2

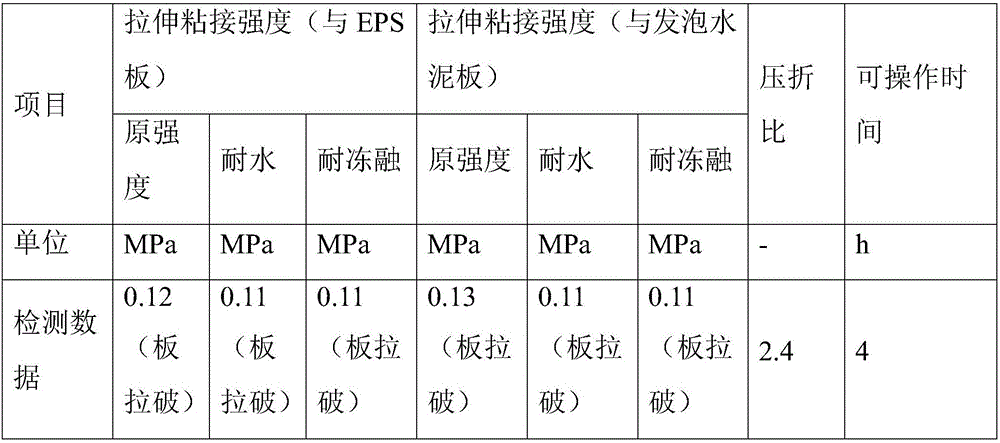

[0022] The invention provides a dry plastering mortar additive, which comprises the following components: 3 kg of hydroxypropyl methylcellulose with a viscosity of 80,000 to 120,000, 20 kg of redispersible latex powder, 0.5kg for silicone water repellent, 1.0kg for starch ether, 1.0kg for calcium formate, 2kg for polycarboxylate superplasticizer with polyester structure, 4kg for polyvinyl alcohol 2488, and 1.8kg for modified wood fiber , the modified PVAC is 2kg. When preparing the dry material of the plastering mortar additive, a variable speed mixer is used for variable speed stirring. First, the modified wood fiber and the polycarboxylate water reducer are stirred at high speed for 3 minutes, and then the organic silicon water repellent is added. After stirring at a medium speed for 3 minutes, finally add hydroxypropyl methylcellulose, redispersible latex powder, starch ether, calcium formate, polyvinyl alcohol, and modified PVAC and stir at a low speed for 6 minutes to prep...

Embodiment 3

[0027] The invention provides a dry mortar additive material, which comprises the following components: 2.5 kg of hydroxypropyl methylcellulose with a viscosity of 80,000 to 120,000, and 15 kg of redispersible latex powder , 0.4kg for silicone water repellent, 0.7kg for starch ether, 0.8kg for calcium formate, 1.5kg for polycarboxylate water reducer with polyester structure, 3kg for polyvinyl alcohol 2488, and 2.2kg for modified wood fiber kg, the modified PVAC is 2kg. When preparing the dry material of the plastering mortar additive, a variable speed mixer is used for variable speed stirring. First, the modified wood fiber and the polycarboxylate water reducer are stirred at high speed for 3 minutes, and then the organic silicon hydrophobic After stirring at a medium speed for 3 minutes, finally add hydroxypropyl methylcellulose, redispersible latex powder, starch ether, calcium formate, polyvinyl alcohol, and modified PVAC and stir at a low speed for 6 minutes to prepare the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com