A low-energy recovery system and process for abamectin extraction solvent

A technology for abamectin and solvent extraction, applied in the field of low energy consumption recovery systems, can solve problems such as energy waste, and achieve the effects of high efficiency utilization and high solvent recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

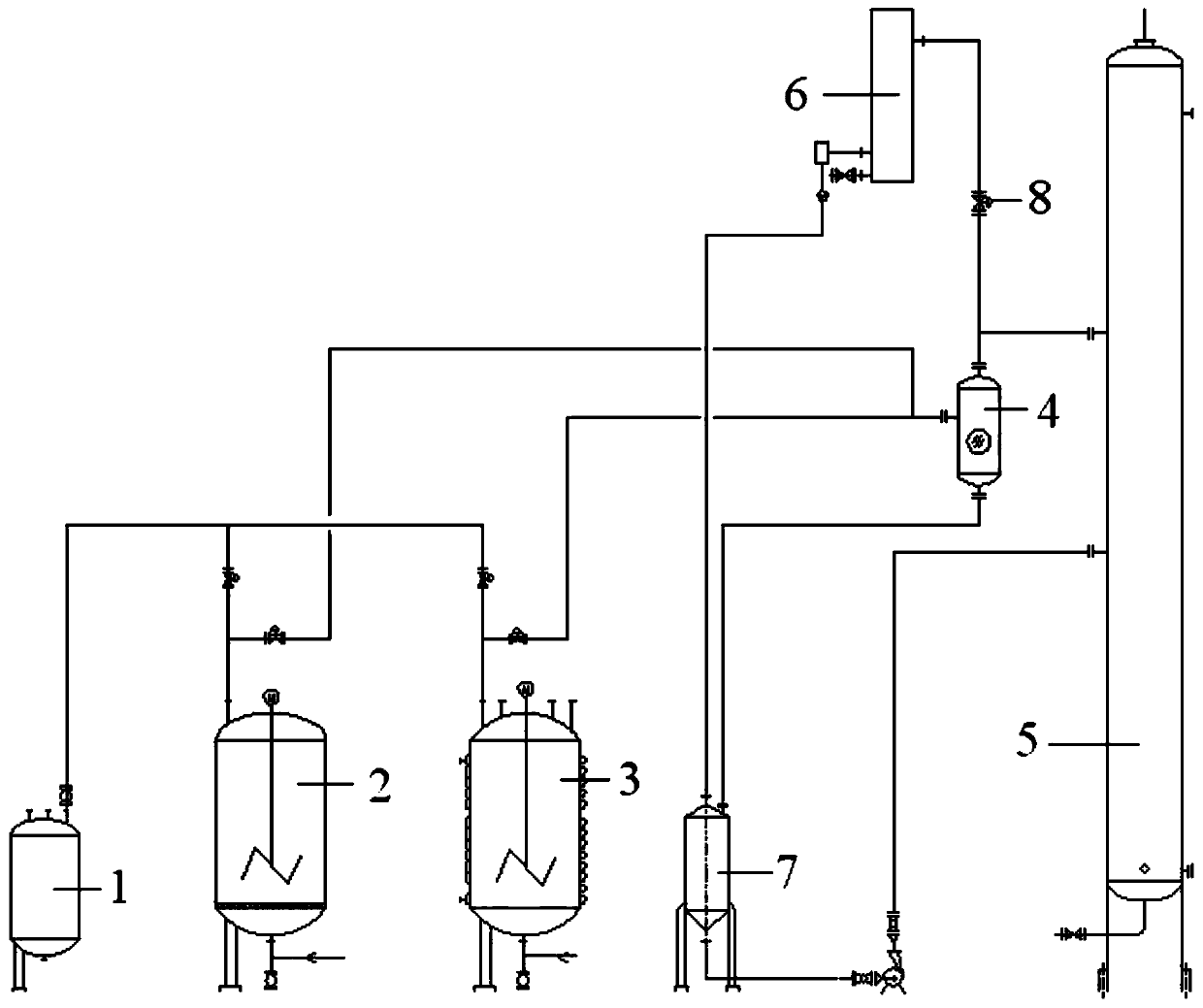

[0036] A kind of recovery system of abamectin extraction solvent, this system comprises methanol storage tank 1, leaching column 2, crystallization tank 3, methanol vapor buffer tank 4, rectification tower 5, condenser 6 and methanol collection tank 7;

[0037] The discharge port of the methanol storage tank 1 is connected with the feed port of the leaching tank 2, the discharge port of the leaching tank 2 is connected with the feed port of the crystallization tank 3, and the leaching tank 2 and crystallization tank 3 steam outlets are connected with the inlet of methanol vapor buffer tank 4 respectively, and the upper end of described methanol vapor buffer tank 4 is connected with rectifying column 5 and condenser 6 respectively, and described methanol vapor buffer tank The lower end of 4 is connected with methanol collection tank 7; described condenser 6 is connected with methanol collection tank 7, and described methanol collection tank 7 is also connected rectification colu...

Embodiment 2

[0041] A kind of recovery process that utilizes the system of embodiment 1 to Abamectin extraction solvent, comprises steps as follows:

[0042] Methanol is pumped into the extraction column 2 from the methanol storage tank 1 to extract the dry powder of abamectin mycelium, and the extraction solution is transferred to the crystallization tank 3 for crystallization, and the extraction column 2 and crystallization The bottom of the tank 3 is fed with hot steam to heat and evaporate the methanol, and the wet fungus residue of abamectin adsorbed with methanol in the extraction column 2 is heated up to 90-95°C and kept for 2-3 hours; Raise the temperature of the material to 60-70°C and keep it for 2-3 hours, then raise the temperature to 70-80°C and keep it for 4-6 hours;

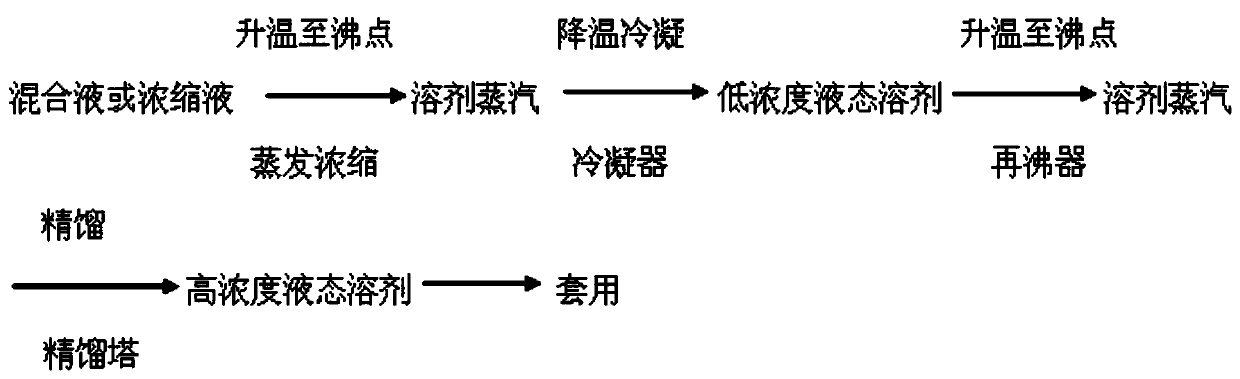

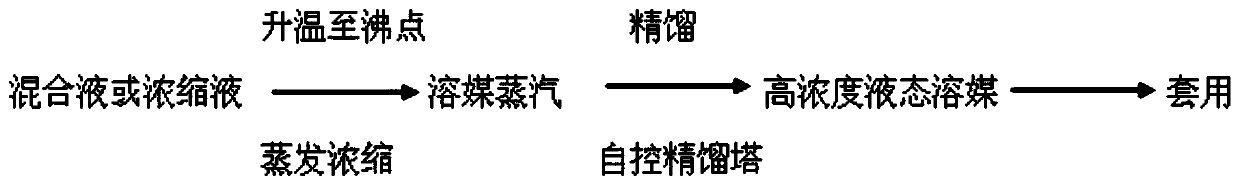

[0043] The methanol vapor in the leaching column 2 and the crystallization tank 3 is transported to the methanol vapor buffer tank 4 through respective pipelines for buffering, and then the buffered methanol va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com