Method for in-situ polymerization preparation of hyperbranched polyamide grafted carbon nanotubes

A technology of hyperbranched polyamide and carbon nanotubes, which is applied in the field of surface modification of carbon nanotubes, can solve the problems that carbon nanotubes are difficult to disperse and dissolve, difficult to uniformly disperse, thermodynamically unstable, etc., so as to improve performance and improve dispersion. The effect of sex, high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

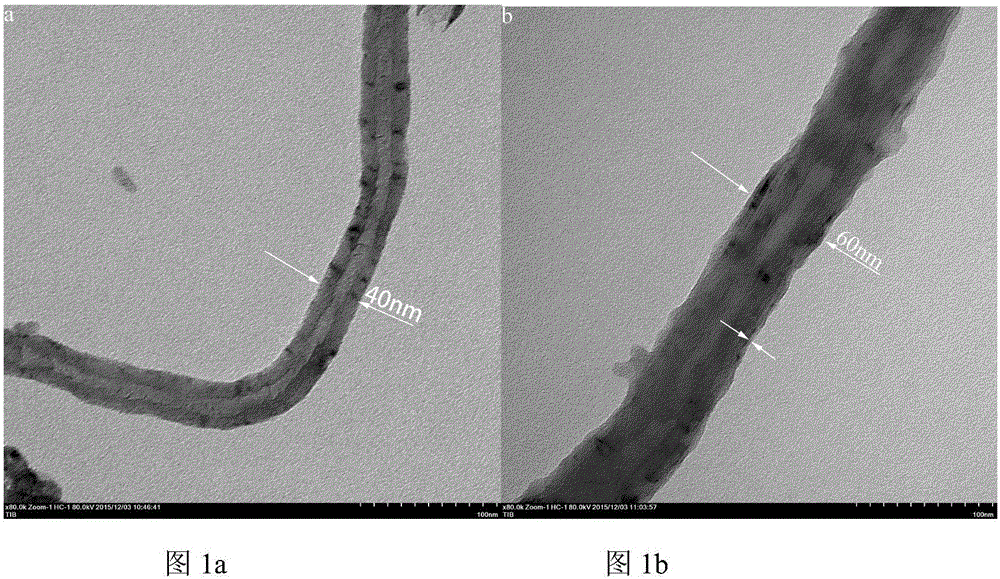

[0026] Using multi-walled carbon nanotubes prepared by catalytic pyrolysis as raw materials, after acidification, in the presence of triphenyl phosphite and pyridine, polymerized with tris(3-aminophenyl)phosphine oxide and adipic acid, the obtained In situ modification of carbon nanotubes by hyperbranched polyamides.

[0027] (1) Weigh 2g of carbon nanotubes, mix concentrated sulfuric acid and concentrated nitric acid at a ratio of 3:1 by volume, add 240ml of mixed acid, ultrasonicate at 40kHz for 0.5h, then stir strongly for 0.5h, heat up to 60°C, continue Stir for 4 hours, filter with a microporous membrane after the reaction is completed, wash with distilled water repeatedly until neutral, and vacuum dry at 120°C for 12 hours to obtain carboxylated carbon nanotubes;

[0028] (2) Weigh 27.8% of triphenylphosphine oxide in a flask, add 100ml of concentrated sulfuric acid, stir to dissolve, mix 60ml of concentrated sulfuric acid and 16ml of fuming nitric acid, then add the mix...

Embodiment 2

[0034] Using multi-walled carbon nanotubes prepared by catalytic pyrolysis as raw materials, after acidification, in the presence of triphenyl phosphite and pyridine, polymerized with tris(3-aminophenyl)phosphine oxide and adipic acid, the obtained In situ modification of carbon nanotubes by hyperbranched polyamides.

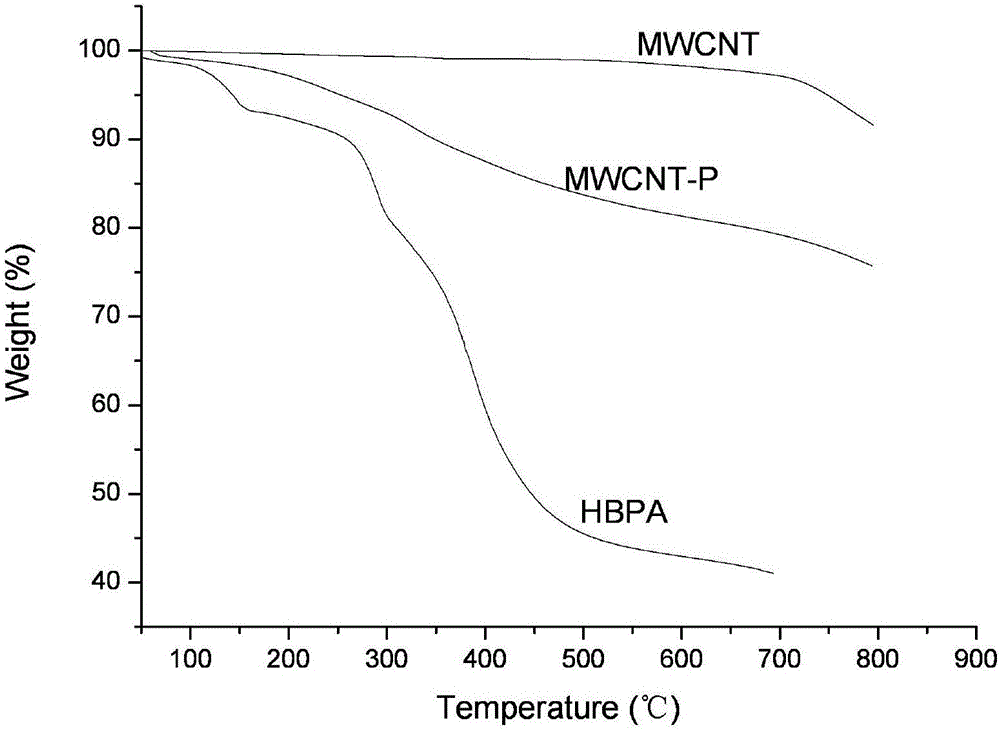

[0035] Steps (1), (2), and (3) are the same as in Example 1, and the addition of acidified carbon nanotubes in step (4) is changed to 10% of the total mass of three (3-aminophenyl) phosphine oxide and adipic acid , other technological processes remain unchanged, the target product is obtained, thermal analysis shows that the grafting rate of hyperbranched polyamide is 31%.

Embodiment 3

[0037] Using multi-walled carbon nanotubes prepared by catalytic pyrolysis as raw materials, after acidification, in the presence of triphenyl phosphite and pyridine, polymerized with tris(3-aminophenyl)phosphine oxide and adipic acid, the obtained In situ modification of carbon nanotubes by hyperbranched polyamides.

[0038] Steps (1), (2), and (3) are the same as in Example 1, and the addition of acidified carbon nanotubes in step (4) is changed to 5% of the total mass of three (3-aminophenyl) phosphine oxide and adipic acid , other technical processes remain unchanged, the target product is obtained, thermal analysis shows that the grafting rate of hyperbranched polyamide is 29%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com