High-voltage rapidly charged lithium ion battery and preparation method thereof

A lithium-ion battery, high-voltage technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of shortening battery charging time, achieve product quality that is difficult to control, internal resistance is small, and contributes to Effect of rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

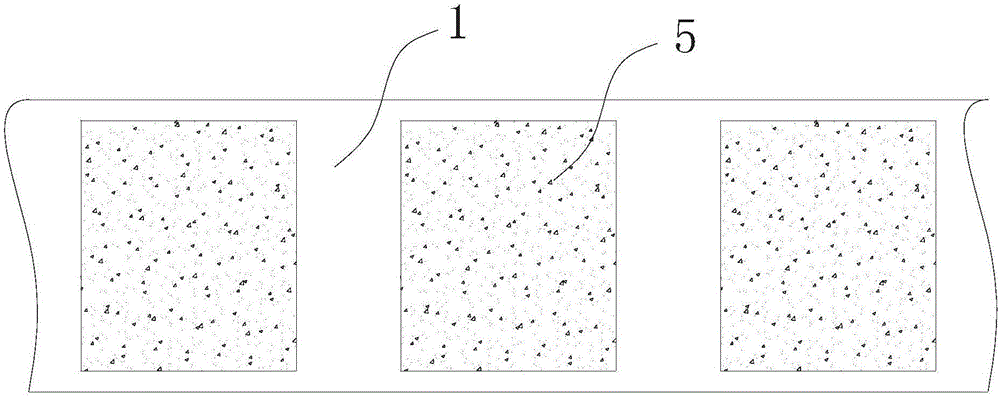

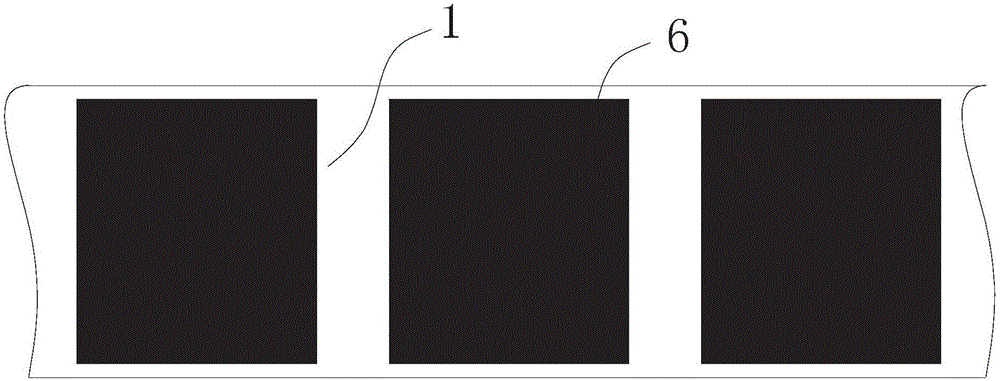

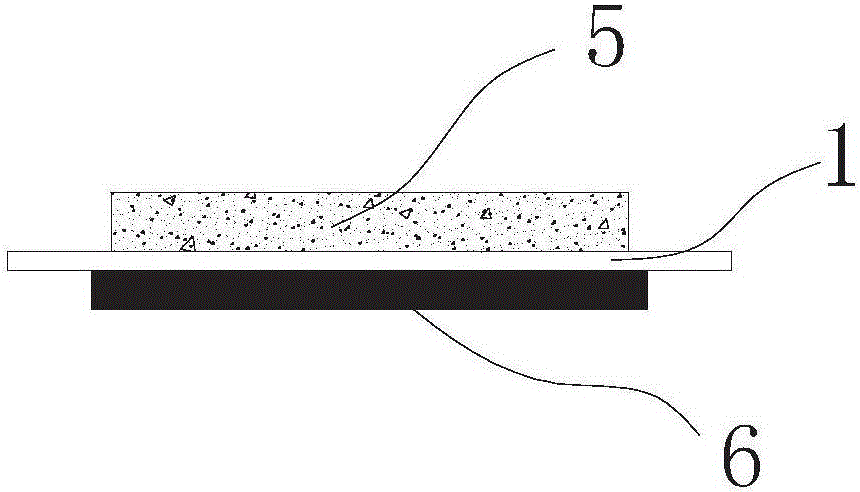

[0058] A high-voltage fast-charge lithium-ion battery, such as Figure 1 to Figure 15 As shown, it includes a separator 1, a pole piece, an electrolyte, a positive electrode collector 2, a negative electrode collector 3 and an aluminum-plastic film 4. Coating the positive electrode material to form the positive electrode 5 and coating the negative electrode material to form the negative electrode 6 are then die-cut and cut. The negative electrode material dressing area corresponding to the negative electrode 6 on the separator 1 covers the positive electrode material dressing area corresponding to the positive electrode 5. The die-cut diaphragm covers The dressing area corresponding to the positive electrode 5 and the negative electrode 6 respectively.

[0059] like Figure 4 As shown, two sheet-shaped separators (1a, 1b) with positive and negative electrodes after thermal die-cutting are arranged side by side and the polar materials on the same side of the separator are arra...

Embodiment 2

[0075] The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here; the difference is that the materials selected in this embodiment are different from those of Embodiment 1, as follows:

[0076] Step 1, select a diaphragm made of PP material as the coating substrate;

[0077] Step 2, using the intermittent coating method, at the positive corresponding positions on both sides of the diaphragm substrate, one side of the diaphragm substrate is coated with the lithium manganate material corresponding to the positive electrode, and the other side of the diaphragm substrate is coated with the corresponding negative electrode. The lithium titanate material, wherein, the lithium titanate material dressing area corresponding to the negative electrode covers the lithium manganate material dressing area corresponding to the positive electrode, and the separator covers the dressing areas corresponding to the negative electrode and the positive elect...

Embodiment 3

[0088] The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here; the difference is that the materials selected in this embodiment are different from those of Embodiment 1, as follows:

[0089] Step 1, select a diaphragm made of a combination of PE and double-sided ceramics as the coated substrate;

[0090] Step 2, using the intermittent coating method, at the corresponding positions on both sides of the diaphragm substrate, one side of the diaphragm substrate is coated with the nickel cobalt lithium manganese oxide material corresponding to the positive electrode, and the other side of the diaphragm substrate is single-coated The lithium titanate material corresponding to the negative electrode, wherein the lithium titanate material dressing area corresponding to the negative electrode covers the nickel cobalt lithium manganate material dressing area corresponding to the positive electrode, and the separator covers the dressing areas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com