Non-return ring free multiaxial volume pulse injection forming method and device

An injection molding device and injection molding technology, which are applied in the injection molding of plastic blending modified materials and long-fiber online compounding materials, and in the field of injection molding, which can solve the problems of poor plasticization mixing effect, high energy consumption, and long thermomechanical process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

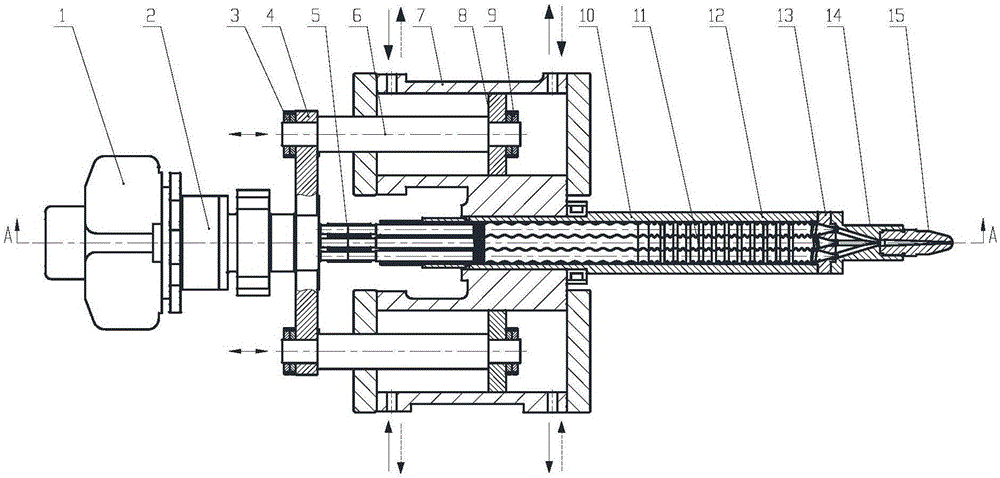

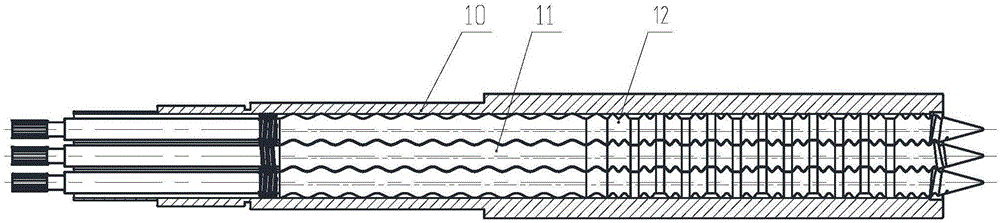

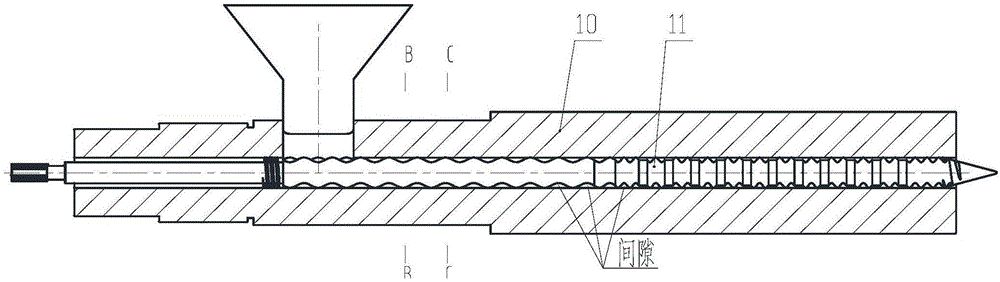

[0038] refer to figure 1 , a multi-axis (three-axis) volume pulsation injection molding device without check ring, including oil motor 1, power distributor 2, first locking round nut 3, motor seat 4, spline sleeve 5, plunger rod 6. Injection cylinder 7, injection piston 8, second locking round nut 9, barrel 10, first eccentric rotor 11, second eccentric rotor 12, barrel head 13, nozzle connection seat 14 and nozzle 15; oil motor 1 It is connected with the power distributor 2 through screws, and the power distributor 2 is fixed on the motor base 4; the plunger rod 6 of the injection cylinder, the motor base 4 and the injection piston 8 are respectively locked by the first locking round nut 3 and the second locking nut. The round nut 9 is connected, the injection piston 8 is placed in the oil cylinder 7, and the plunger piston 8 reciprocates in the oil cylinder under the action of oil pressure; the motor seat 4 is installed on the guide rail of the frame, driven by the hydraulic...

Embodiment 2

[0047] The main difference between embodiment 2 and embodiment 1 is the number of rotors. In embodiment 1, there are 3 eccentric rotors, while in embodiment 2 there are only 2 eccentric rotors. refer to Figure 6 , the multi-axis (two-axis) volume pulsation injection molding device without non-return ring in this embodiment mainly includes an oil motor 16, a power distributor 17, a first locking round nut 18, a motor seat 19, a spline sleeve 20, a column Plug rod 21, injection cylinder 22, injection piston 23, second locking round nut 24, double hole barrel 25, first eccentric rotor 26, second eccentric rotor 27, barrel head 28, nozzle connecting seat 29, nozzle 30 and other parts. The oil motor 16 and the power distributor 17 are connected by screws and fixed on the motor base 19; the motor base 19 is connected with the injection plunger rod 21 and the injection piston 23 through the first locking round nut 18 and the second locking round nut 24, The plunger piston 23 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com